Nitrogen doped TiO2 modified glass-carbon electrode, preparation method and applications thereof

A technology of glassy carbon electrode and nitrogen doping, which is applied in the field of electrochemical materials, can solve few problems, and achieve the effects of high peak current intensity, stable cyclic voltammetry performance, and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A nitrogen-doped TiO 2 A method for preparing a modified glassy carbon electrode, comprising the steps of:

[0040] A. Pretreatment of glassy carbon electrodes:

[0041] Take an appropriate amount of polishing powder in a beaker, drop an appropriate amount of distilled water to make the polishing powder into a paste, and transfer it to a silk cloth to polish the glassy carbon electrode. The polished glassy carbon electrode is ultrasonically treated with nitric acid, acetone, and ethanol Wash for 5-10 minutes each time until it is clean;

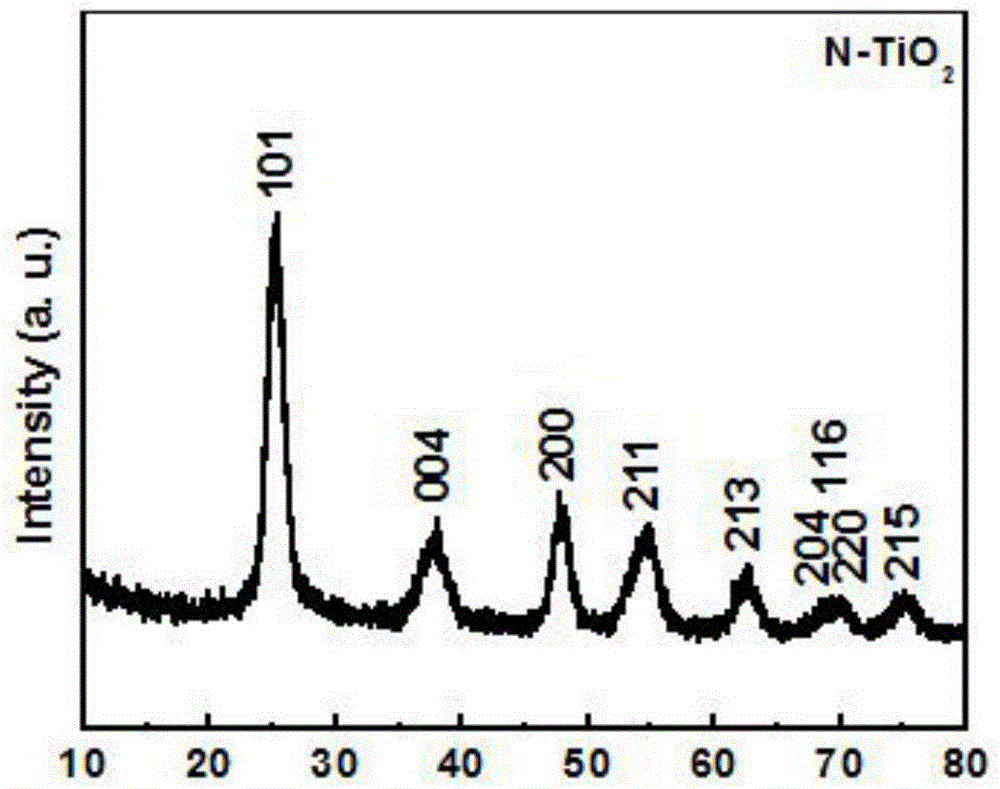

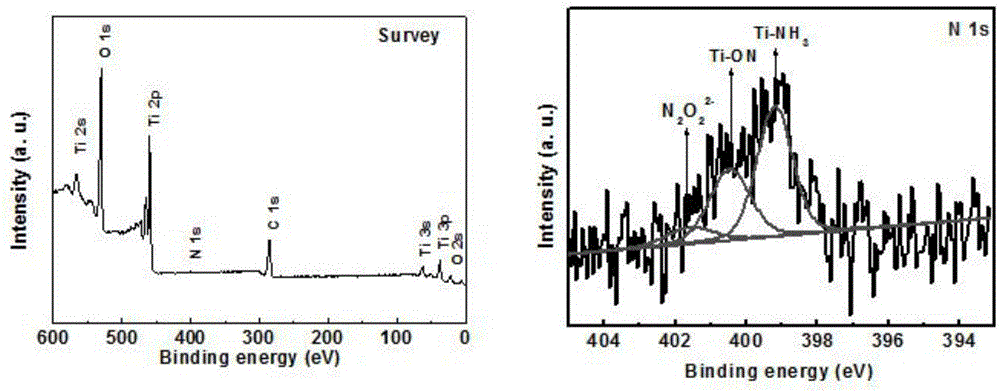

[0042] B. Nitrogen-doped TiO 2 Preparation of:

[0043] B1. Add 2mL of tetrabutyl titanate to every 38mL of absolute ethanol solution under magnetic stirring conditions, and mix thoroughly to obtain a mixed solution 1, then add 2mmol of sodium nitrate to the mixed solution 1, and then add 2mmol of ammonium chloride And mix evenly to get the mixed solution 2, then transfer the mixed solution 2 to the polytetraethylene liner, heat it...

Embodiment

[0054] A nitrogen-doped TiO 2 A method for preparing a modified glassy carbon electrode, comprising the steps of:

[0055] 1. Pretreatment of glassy carbon electrodes

[0056] Take an appropriate amount of polishing powder in a beaker, drop an appropriate amount of distilled water to make the polishing powder into a paste, and polish the glassy carbon electrode. The polished glassy carbon electrode is ultrasonically washed with nitric acid, acetone, and ethanol in sequence, each time for 5 to 10 minutes until cleaned.

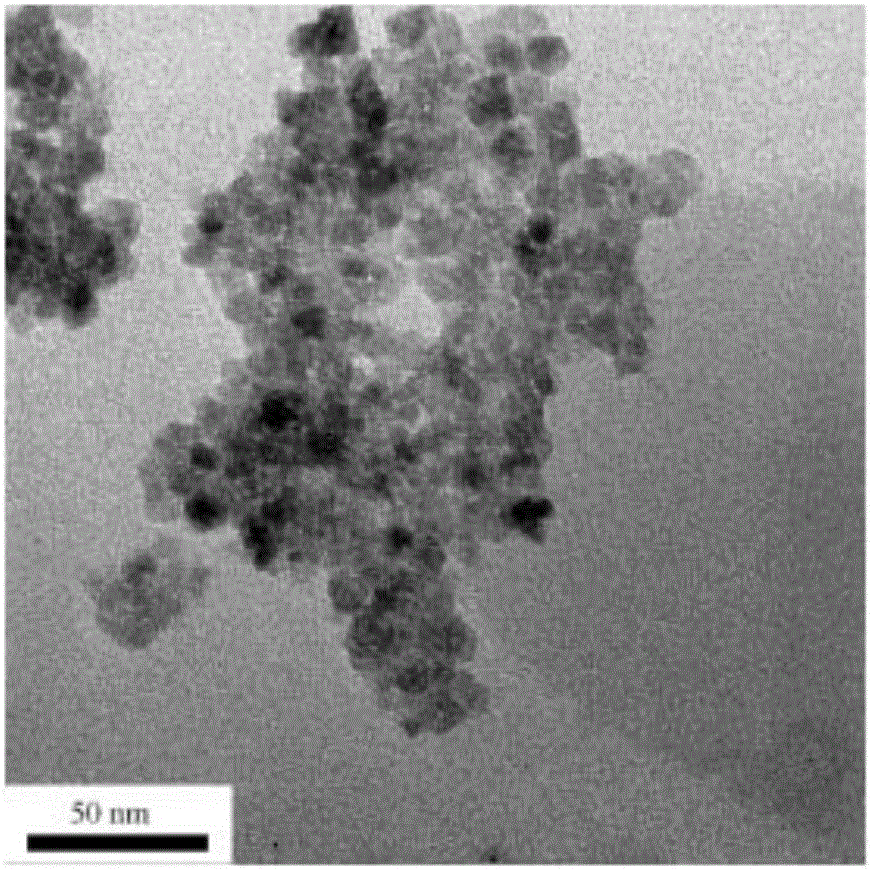

[0057] 2. Nitrogen-doped TiO 2 preparation of

[0058] Add 2mL tetrabutyl titanate to 38mL absolute ethanol solution under magnetic stirring, mix the above solution evenly, first add 2mmol sodium nitrate, then add 2mmol ammonium chloride, transfer the mixed solution to the polytetraethylene liner, After being heated in an oven at 180° C. for 12 hours, it was naturally cooled to room temperature. The obtained product is filtered by suction, washed with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com