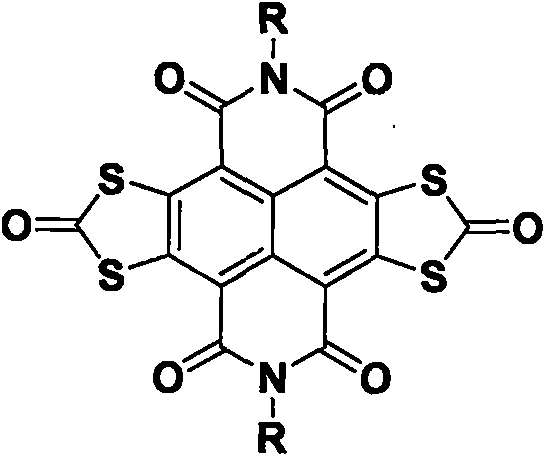

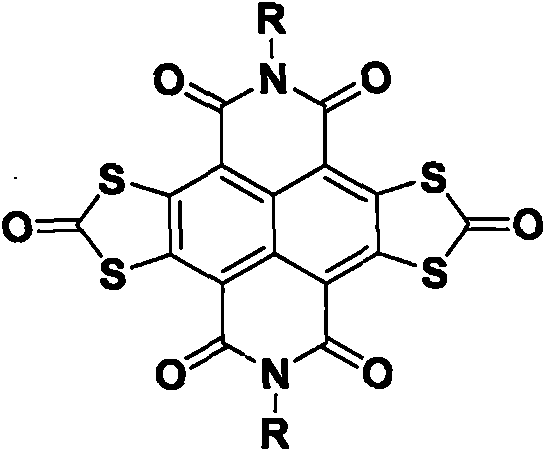

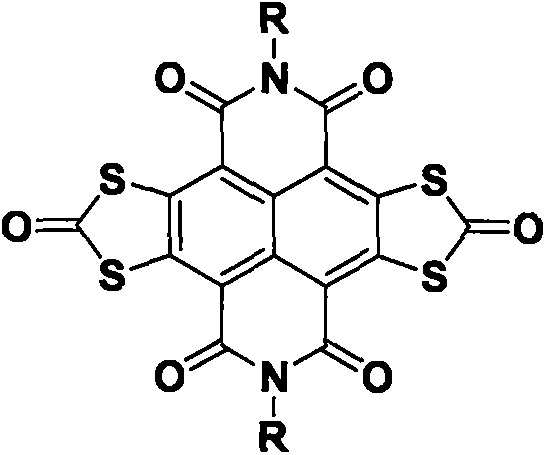

Preparation method of (1,3-dithio-2-carbonyl)-condensed naphthaldiimide/carbon nanotube composite thermoelectric material

A technology of naphthalene diimide and carbon nanotubes is applied in the field of preparing composite thermoelectric materials by physical blending, which can solve the problems of complex polymerization reaction conditions of conductive polymers, insufficient quantification of polymerization degree, affecting the thermoelectric properties of materials, and the like. Achieve the effects of good component dispersion uniformity, easy operation and improved thermoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 13 mg of single-walled carbon nanotubes to 35 mL of ethanol solvent, and ultrasonically disperse for 30 min;

[0029] (2) Add 13 mg of (1,3-dithio-2-carbonyl) fused naphthalene diimide to 7 mL of dichloromethane solvent, and stir at room temperature until the solid is basically dissolved;

[0030] (3) slowly drop the suspension obtained in step (2) into the suspension obtained in step (1);

[0031] (4) The mixture obtained in step (3) was stirred at room temperature for 24h;

[0032] (5) The reaction mixture obtained in step (4) was vacuum filtered to obtain a yellow-black solid filter membrane. Wash the yellow-black solid several times with ethanol, dry it, and finally obtain a relatively high-purity (1,3-dithio-2-carbonyl) fused naphthalene diimide / carbon nanotube composite thermoelectric material, whose electrical conductivity 144.1S cm -1 , Seebeck coefficient is 52.2μV / K.

Embodiment 2

[0034] According to the method and steps described in Example 1, just add 13 mg of single-walled carbon nanotubes in step (1) to 35 mL of methanol, and filter the yellow-black solid membrane obtained in step (4) in step (5). Multiple washes were performed with methanol. Finally, the conductivity of (1,3-dithio-2-carbonyl)-fused naphthalene diimide / carbon nanotube composite thermoelectric material was 138.2 S cm -1 , Seebeck coefficient is 51.2μV / K.

Embodiment 3

[0036] According to the method and steps described in Example 1, only 13 mg of (1,3-dithio-2-carbonyl) fused naphthalene diimide in step (2) was added to 7 mL of chloroform solvent. Finally, the conductivity of (1,3-dithio-2-carbonyl)-fused naphthalene diimide / carbon nanotube composite thermoelectric material was 135.8 S cm -1 , Seebeck coefficient is 51.5μV / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com