Preparation method of silica-modified multi-spherical-cavity carbon material and application of carbon material to fuel cell membrane electrode

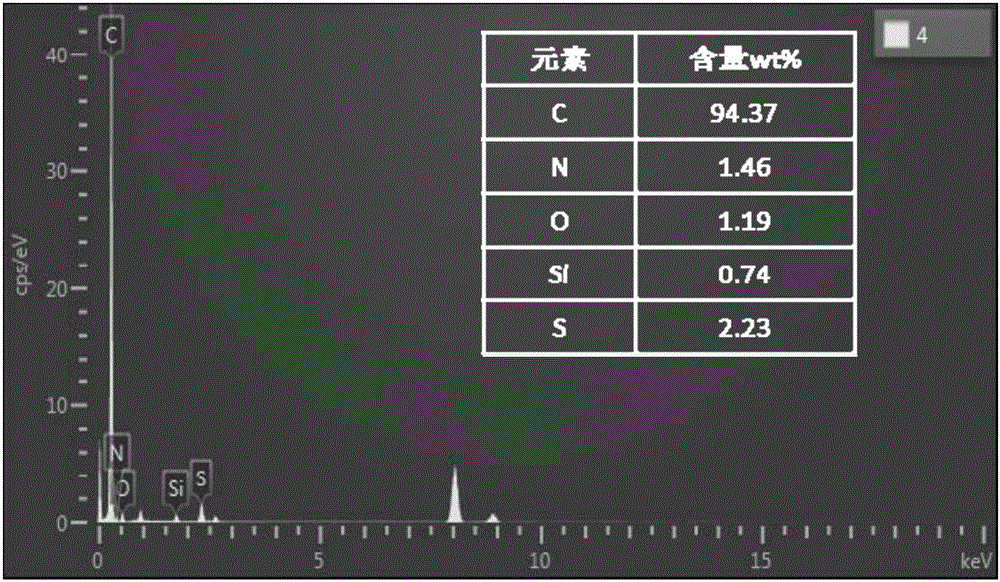

A technology of silicon dioxide and carbon materials, which is applied in the direction of fuel cells, battery electrodes, silicon dioxide, etc., can solve the problems of increasing energy consumption and increasing the complexity of batteries, and achieves long service life, good performance and stability, and relatively The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

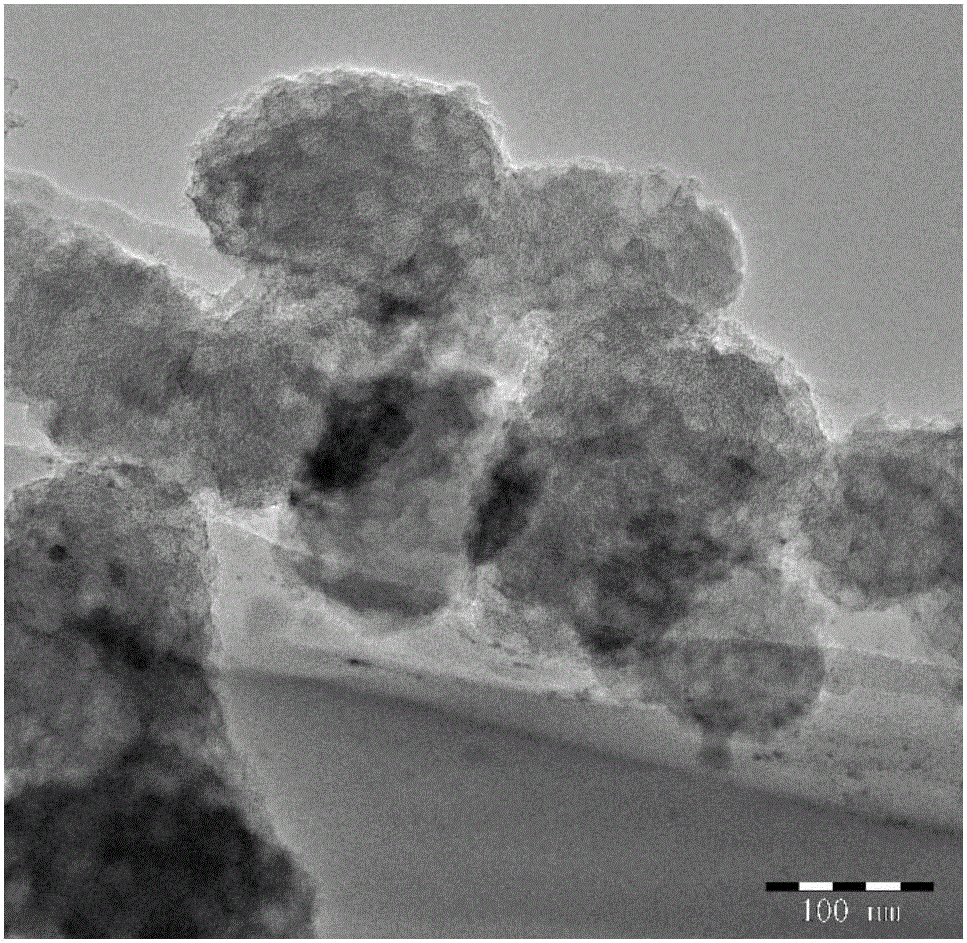

[0046] (1) SiO 2 - Preparation of MSCC-2h material:

[0047] 1) Take 82 mg, 2.1 mL and 45 mL of L-arginine, cyclohexane and water, respectively, and fully dissolve them under stirring at 60°C to obtain a mixed solution A;

[0048] 2) Add 2.1 mL tetraethyl orthosilicate to the mixed solution A obtained in step 1) at a rate of 1 drop / second, keep the temperature and continue stirring for 12 h to obtain the silica pellet mother solution B;

[0049] 3) Add the growth solution prepared with 5 mL cyclohexane, 4 mL tetraethyl orthosilicate and 50 mL water to the silica pellet mother liquid B obtained in step 2), keep the temperature and continue stirring for 15 h to obtain Silica sol C;

[0050] 4) Add 0.8 g of PVP-k30 to the silica gel C obtained in step 3) to obtain a mixed solution D;

[0051] 5) Adjust the pH value of the mixed solution D obtained in step 4) to 0 with concentrated hydrochloric acid, add 6.7 mL of aniline to the mixed solution D under continuous stirring, and t...

Embodiment 2

[0060] (1) SiO 2 - Preparation of MSCC-2h material:

[0061] 1) Take 82 mg, 4.2 mL and 90 mL of L-arginine, cyclohexane and water, respectively, and fully dissolve them under stirring at 40°C to obtain a mixed solution A;

[0062] 2) Add 5.2 mL of ethyl orthosilicate to the mixed solution A obtained in step 1) at a rate of 2 drops / second, keep the temperature and continue stirring for 18 h to obtain the silica pellet mother solution B;

[0063] 3) Add the growth solution prepared with 45 mL cyclohexane, 24 mL tetraethyl orthosilicate and 300 mL water to the silica pellet mother liquid B obtained in step 2), keep the temperature and continue stirring for 22.5 h to obtain silica Sol C;

[0064] 4) Add 0.5 g PVP-k10 and 0.5 g PVP-k15 to the silica gel C obtained in step 3) to obtain a mixed solution D;

[0065] 5) Adjust the pH value of the mixed solution D obtained in step 4) to 0.15 with concentrated hydrochloric acid, add 18.7 mL of aniline to the mixed solution D under con...

Embodiment 3

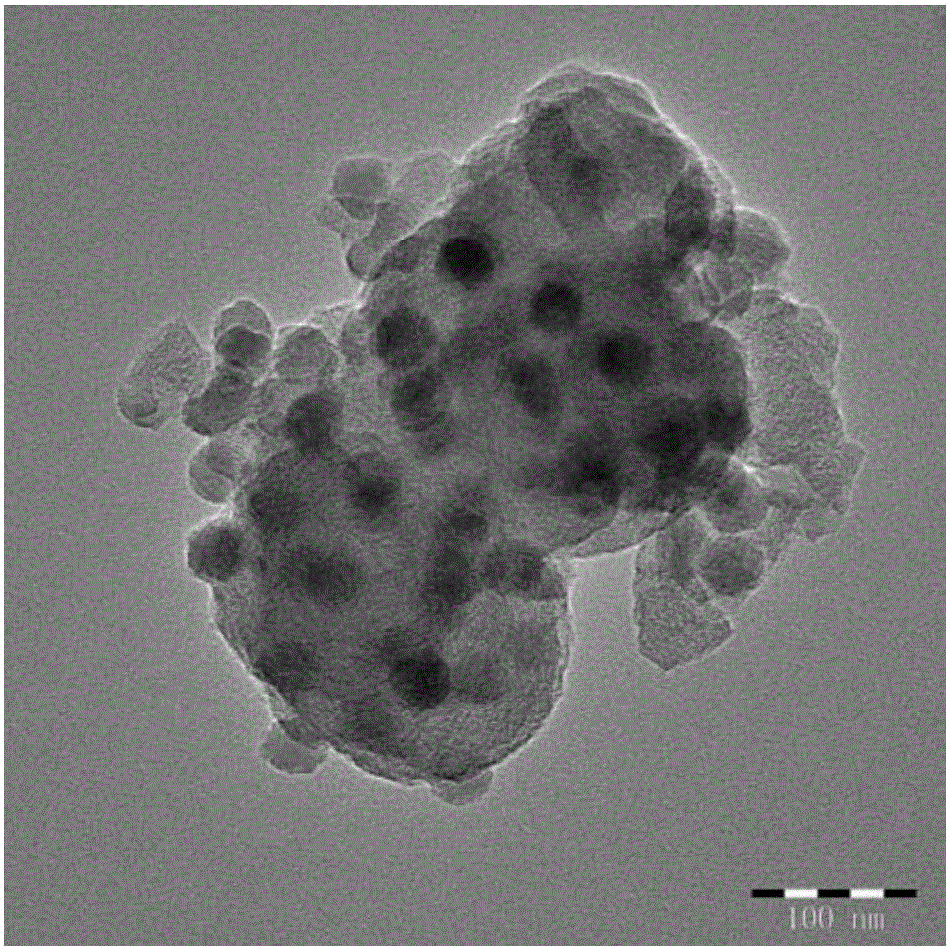

[0072] (1) SiO 2 - Preparation of MSCC-4h material:

[0073] 1) Take 82 mg, 6.3 mL and 135 mL of L-arginine, cyclohexane and water, respectively, and fully dissolve them under stirring at 80°C to obtain a mixed solution A;

[0074] 2) Add 8.32 mL tetraethyl orthosilicate to the mixed solution A obtained in step 1) at a rate of 1.5 drops / second, keep the temperature and continue stirring for 24 h to obtain the silica pellet mother solution B;

[0075] 3) Add the growth solution prepared with 120 mL cyclohexane, 60 mL tetraethyl orthosilicate and 750 mL water to the silica pellet mother liquid B obtained in step 2), keep the temperature and continue stirring for 30 h to obtain silica Sol C;

[0076] 4) Add 0.625 g PVP-k17 and 0.625 g PVP-k30 to the silica gel C obtained in step 3) to obtain a mixed solution D;

[0077] 5) Adjust the pH value of the mixed solution D obtained in step 4) to 0.3 with concentrated hydrochloric acid, add 31.7 mL of aniline to the mixed solution D u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com