Preparation method of two-component automotive cathodic electrophoretic coating and preparation method thereof

A cathodic electrophoretic coating, two-component technology, applied in the field of coatings, can solve the problems of high toxicity, reduce energy consumption, and environmental protection, and achieve the effect of strong coating ability, good uniformity, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

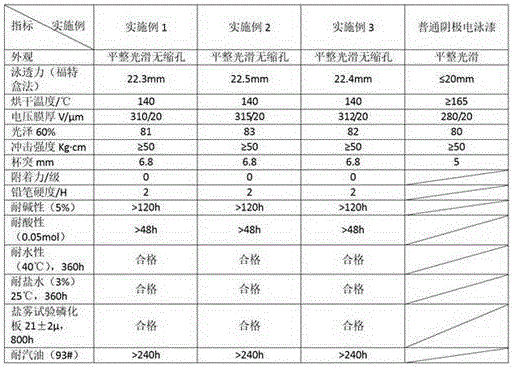

Examples

Embodiment 1

[0032] A two-component automotive cathodic electrophoretic coating, comprising, in parts by mass, 1 part of color paste, 6 parts of emulsion and 5 parts of deionized water;

[0033] The color paste formula includes 20 parts of water-based cationic epoxy resin, 20 parts of pigment and filler, 10 parts of solvent, 0.5 part of non-toxic drier, 0.5 part of dispersant, and 30 parts of deionized water;

[0034] The emulsion formula includes, 40 parts of modified epoxy resin A, 10 parts of modified epoxy resin B, 10 parts of curing agent, 3 parts of diketimine of diethylenetriamine and 2 parts of N-methylethanolamine , 0.1 part of emulsifier, 0.1 part of acetic acid and 30 parts of deionized water; the modified epoxy resin A formula includes, 10 parts of bisphenol A, 40 parts of epoxy resin, 8 parts of solvent, 4 parts of bisphenol A polyoxygen Vinyl ether, 10 parts of polyether diols with a number average molecular weight of 400-1500; the modified epoxy resin B formula includes 10 p...

Embodiment 2

[0040] A two-component automotive cathodic electrophoretic paint, comprising, in parts by mass, 2 parts of color paste, 6 parts of emulsion and 7 parts of deionized water;

[0041] The color paste formula includes 30 parts of water-based cationic epoxy resin, 40 parts of pigments and fillers, 20 parts of solvent, 1.5 parts of non-toxic drier, 2 parts of dispersant, and 50 parts of deionized water;

[0042] The emulsion formula includes, 50 parts of modified epoxy resin A, 20 parts of modified epoxy resin B, 30 parts of curing agent, ketimine of 4 parts of aminoethylethanolamine and 3 parts of diethanolamine, 2 parts of emulsifier, 1 part of acetic acid and 50 parts of deionized water; the modified epoxy resin A formula includes, 20 parts of bisphenol A, 60 parts of epoxy resin, 16 parts of solvent, 16 parts of bisphenol A polyoxypropylene ether, 35 parts A polyether diamine with an average molecular weight of 400-1500; the modified epoxy resin B formula includes 20 parts of bi...

Embodiment 3

[0048] A two-component automotive cathodic electrophoretic coating, comprising, in parts by mass, 1 part of color paste, 5 parts of emulsion and 6 parts of deionized water;

[0049] The color paste formula includes 35 parts of water-based cationic epoxy resin, 25 parts of pigment and filler, 15 parts of solvent, 0.7 part of non-toxic drier, 1 part of dispersant, and 40 parts of deionized water;

[0050] The emulsion formula includes, 45 parts of modified epoxy resin A, 15 parts of modified epoxy resin B, 20 parts of curing agent, ketimine of 4 parts of aminoethylethanolamine and 3 parts of diethanolamine, 0.8 part of emulsifier, 0.5 parts of acetic acid and 40 parts of deionized water; the modified epoxy resin A formula includes, 15 parts of bisphenol A, 50 parts of epoxy resin, 12 parts of solvent, 10 parts of bisphenol A polyoxypropylene ether, 25 parts of A polyether diamine with an average molecular weight of 400 to 1500; the modified epoxy resin B formula includes 15 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com