A Method to Simultaneously Improve the Hardness and Toughness of (cr,fe)7c3

A toughness and hardness technology, applied in the field of improving the hardness and toughness of 7C3 at the same time, can solve problems such as accelerating alloy solidification, and achieve the effects of strong wear resistance, simple and easy process, and improved fracture toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

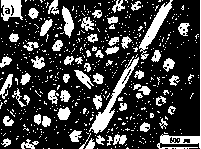

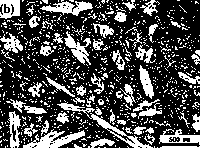

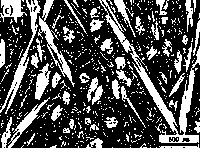

Image

Examples

Embodiment 1

[0036] A kind of (Cr, Fe) in the high chromium cast iron described in this embodiment simultaneously improves 7 C 3 The method for carbide hardness and toughness specifically comprises the following steps:

[0037] (1) Use scrap steel, pig iron, high-carbon ferrochrome, low-carbon ferrochrome and ferrotungsten as raw materials, so that the weight percentages of each component are as follows: 4.50% C, 12.00% Cr, 0.10% Ti, 1.50% Si, and the W content is 1.5%, the rest is Fe;

[0038] (2) Melt the raw materials in step 1 in an intermediate frequency induction furnace. The feeding sequence is to add steel scrap and pig iron first, then add high-chromium cast iron, then add low-chromium cast iron, and finally add ferrotungsten. The temperature of the molten metal reaches 1450°C Finally, use aluminum wire to deoxidize, and then pour the molten metal into the standard Kiel test block sand mold through the ladle, and let it cool naturally for 8 hours to fully dissolve the tungsten e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com