Preparation method of nanofibrous membrane with core/shell structure loaded with traditional Chinese medicine asiaticoside and application in wound dressing

A nanofiber membrane and asiaticoside technology, which is applied in fiber processing, medical science, filament/thread forming, etc., can solve the problem of no obvious promotion effect on wound healing, instability of asiaticoside, easy damage to new tissue, etc. problems, achieve excellent biodegradability, easy large-scale industrial production, and promote wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

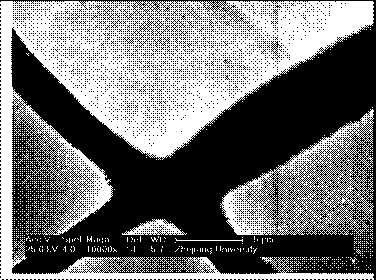

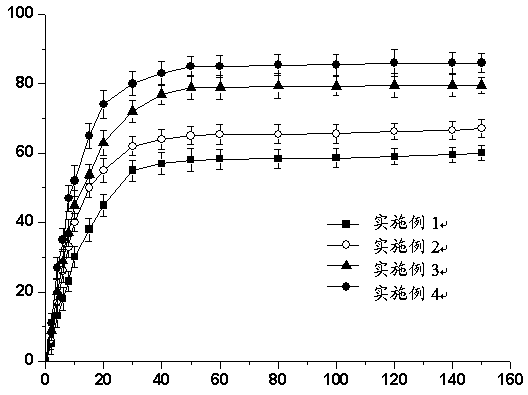

[0041] Dissolve lactic acid / glycolic acid copolymer (PLGA) in a mixed solution of dichloromethane and N,N-dimethylformamide (the volume ratio of dichloromethane to N,N-dimethylformamide is 3:1) , to make a shell spinning solution with a concentration of 0.15 g / mL; dissolve polycaprolactone (PCL) in dichloromethane to form a solution with a concentration of 0.13 g / mL, and add 0.02 g / mL of Centella asiatica Glycosides are formulated as an inner core spinning solution. Add the shell spinning solution and the core spinning solution into two syringes respectively, and connect them to the coaxial electrospinning device through a coaxial needle. When the power supply voltage is 12 kV, the distance between the needle and the receiving substrate is Under the spinning conditions of 13 cm, feeding speed of 0.5 mL / h for the outer layer and 2.0 mL / h for the inner layer, a core / shell nanofiber membrane loaded with asiaticoside was obtained.

Embodiment 2

[0043] Dissolve lactic acid / glycolic acid copolymer (PLGA) in a mixed solution of dichloromethane and N,N-dimethylformamide (the volume ratio of dichloromethane to N,N-dimethylformamide is 3.5:1) , to make a shell spinning solution with a concentration of 0.20 g / mL; dissolve polycaprolactone (PCL) in dichloromethane to form a solution with a concentration of 0.15 g / mL, and add 0.04 g / mL of Centella asiatica Glycosides are formulated as an inner core spinning solution. Add the shell spinning solution and the core spinning solution into two syringes respectively, and connect them to the coaxial electrospinning device through a coaxial needle. When the power supply voltage is 14 kV, the distance between the needle and the receiving substrate is Under the spinning conditions of 14 cm, feeding speed of 0.7 mL / h for the outer layer and 2.4 mL / h for the inner layer, a core / shell nanofiber membrane loaded with asiaticoside was obtained.

Embodiment 3

[0045] Dissolve lactic acid / glycolic acid copolymer (PLGA) in a mixed solution of dichloromethane and N,N-dimethylformamide (the volume ratio of dichloromethane to N,N-dimethylformamide is 4:1) , to make a shell spinning solution with a concentration of 0.23 g / mL; dissolve polycaprolactone (PCL) in dichloromethane to form a solution with a concentration of 0.20 g / mL, and add 0.06 g / mL of Centella asiatica Glycosides are formulated as an inner core spinning solution. Add the shell spinning solution and the core spinning solution into two syringes respectively, and connect them to the coaxial electrospinning device through the coaxial needle. The distance between the needle and the receiving substrate is Under the spinning conditions of 15 cm, feeding speed of 0.9 mL / h for the outer layer and 2.8 mL / h for the inner layer, a core / shell nanofiber membrane loaded with asiaticoside was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com