Multiphase hybrid micro-nano structure magnetic composite material and preparation method thereof

A magnetic composite material and micro-nano structure technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problem of non-uniform dispersion of nanoparticles, achieve excellent biocompatibility, promote adhesion and growth, and have good biological compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

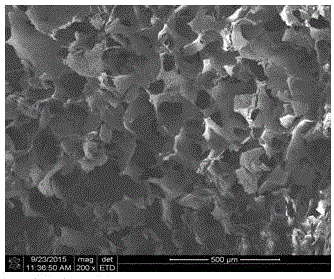

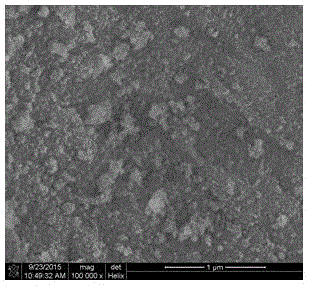

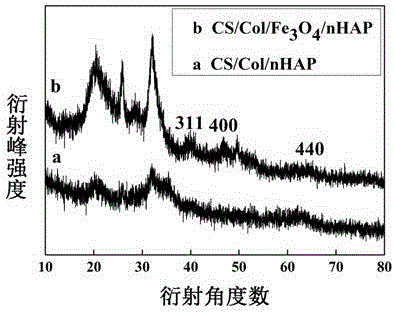

Image

Examples

Embodiment 1

[0035] (1) Weigh 1.0g of chitosan and dissolve it in 1mL of acetic acid solution with a volume fraction of 1% to obtain an acetic acid solution of chitosan; dissolve 8g of bovine collagen in 8mL of secondary water and stir at room temperature for 2 days to obtain bovine Aqueous solution of collagen;

[0036] (2) Slowly add the dissolved bovine collagen into the chitosan acetic acid solution, stir for 0.5h to make it fully mixed;

[0037] (3) Add 3mL, 2mol / L soluble calcium salt solution and stir for 30min, then add 3mL, 1.2mol / L soluble phosphate solution and stir for 4h;

[0038] (4) According to n(Fe 3+ ):n( Fe 2+ )=2:1 after adding 0.8mol soluble ferrous salt and stirring for 30min, then adding 0.4mol soluble ferrous salt and stirring for 30min;

[0039] (5) Add 5mL, 4mg / mL, EDC and 6.25mL, 1mg / mL, NHS mixed cross-linking agent for cross-linking, cross-linking at room temperature for 4 hours; the final mixture is poured into the mold, moved to 3 ℃ refrigerator for 5 hour...

Embodiment 2

[0049] (1) Weigh 1.3g of chitosan and dissolve it in 1.5mL of acetic acid solution with a volume fraction of 1% to obtain an acetic acid solution of chitosan; dissolve 82g of bovine collagen in 85mL of secondary water and stir at room temperature for 2.5d. Obtain the aqueous solution of bovine collagen;

[0050] (2) Slowly add the dissolved bovine collagen into the chitosan acetic acid solution, stir for 0.5h to make it fully mixed;

[0051] (3) Add 2.4mL, 2.5mol / L soluble calcium salt solution and stir for 30min, then add 2.4mL, 1.5mol / L soluble phosphate solution and stir for 4h;

[0052] (4) According to n(Fe 3+ ): n(Fe 2+ )=1.7:1 ratio, after adding 0.51mol soluble ferrous salt and stirring for 30min, then adding 0.3mol soluble ferrous salt and stirring for 30min;

[0053] (5) Add 6.7mL, 3mg / mL, EDC and 8.3mL, 2mg / mL, NHS mixed cross-linking agent for cross-linking, cross-linking at room temperature for 6h; the final mixture is poured into the mold, and moved to a 3°C r...

Embodiment 3

[0056] (1) Weigh 1.25g of chitosan and dissolve it in 2mL of acetic acid solution with a volume fraction of 1.5% to obtain an acetic acid solution of chitosan; dissolve 9g of bovine collagen in 10mL of secondary water and stir at room temperature for 3 days;

[0057] (2) Slowly add the dissolved bovine collagen into the chitosan acetic acid solution, stir for 0.5h to make it fully mixed;

[0058] (3) Add 2mL, 3mol / L soluble calcium salt solution and stir for 30min, then add 2mL, 1.8mol / L soluble phosphate solution and stir for 4h;

[0059] (4) According to n(Fe 3+ ):n( Fe 2+ )=1.9:1 ratio, after adding 0.76mol soluble ferrous salt and stirring for 30min, then adding 0.4mol soluble ferrous salt and stirring for 30min;

[0060] (5) Add 4.5mL, 0.02g / mL, EDC and 5.6mL, 0.03g / mL, NHS mixed cross-linking agent for cross-linking, cross-linking at room temperature for 4h; the final mixture is poured into the mold, and moved to a 4°C refrigerator for pre-freezing 5h, then freeze at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com