Preparation method of nano oxide coated long-life lithium ion sieve adsorbent

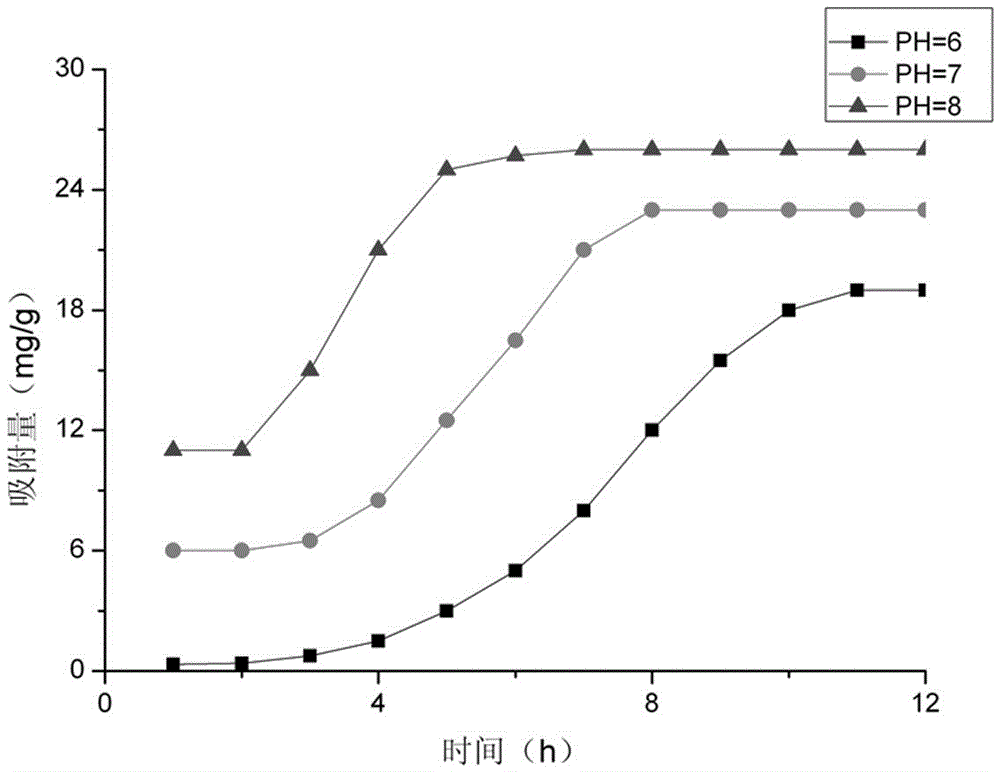

A nano-oxide and adsorbent technology, applied in the field of lithium resource recovery, can solve the problems of low extraction efficiency, difficult commercialization of production capacity, high adsorbent loss rate, increase specific surface area and wettability, improve ion exchange capacity, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

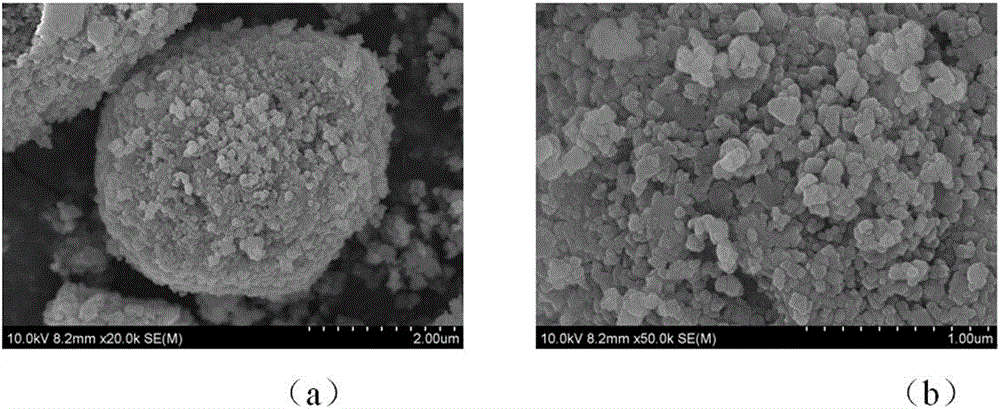

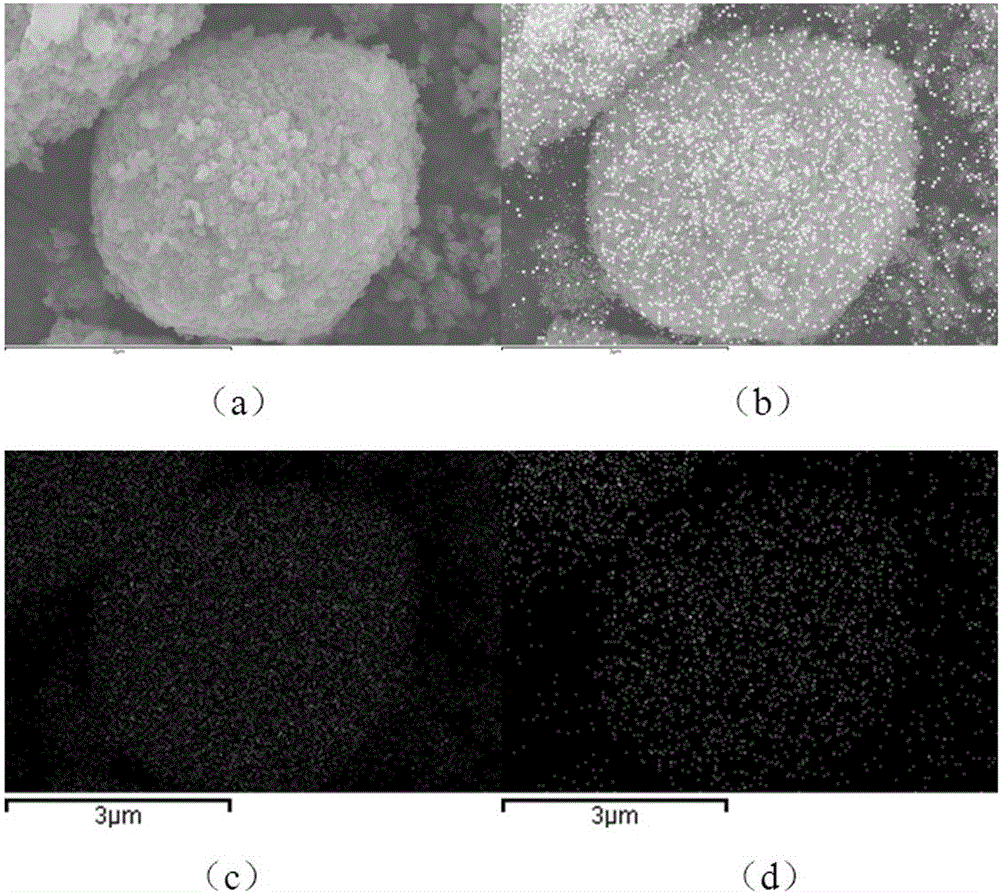

Embodiment 1

[0031] Weigh 1~4g of aluminum nitrate powder, add 20~40ml of absolute ethanol, place it in an ultrasonic device and ultrasonicate for 1~3h, until the aluminum nitrate powder is dispersed and dissolved, and a colorless transparent solution is obtained. Weigh 33.3~66.6gLi 1.6 mn 1.6 o 2 Powder, for completely dispersed powder, add 50~100ml of absolute ethanol, and put it in the ultrasonic equipment for 1~3h to make Li 1.6 mn 1.6 o 2 Dispersion was complete, and a brown viscous suspension was obtained. Then mix the absolute ethanol solution containing aluminum nitrate and the suspension containing powder evenly with a magnetic stirring device, adjust the pH to 8~10 with 1M ammonia water, and at a stirring rate of 200~900r / min, 60~80 The absolute ethanol solvent was evaporated to dryness at low temperature. When the viscosity of the solution gradually increases to the point that it is difficult to stir, place it in a dry blast box at 60-80°C to make it completely dry. After...

Embodiment 2

[0038] Weigh 0.5-1.5g of nano-silica powder, add 20-40ml of absolute ethanol, and place it in an ultrasonic device for 1-3h until the nano-silica powder is dispersed to obtain a milky white suspension. Weigh 33.3~66.6gLi 1.6 mn 1.6 o 2 Powder, for complete dispersion of powder, add 50~100ml of absolute ethanol, and place it in an ultrasonic device for 1~3h to disperse the powder completely, and obtain a brown viscous suspension. Then mix the anhydrous ethanol suspension containing nano-silica and the suspension containing powder evenly with a magnetic stirring device, adjust the pH to 8~10 with 1M ammonia water, and stir at a stirring rate of 200~900r / min , 60 ~ 80 ℃ low temperature evaporation of absolute ethanol solvent. When the viscosity of the solution gradually increases to the point that it is difficult to stir, place it in a dry blast box at 60-80°C to make it completely dry. After cooling, take out the agglomerated, brown powder and grind it in a mortar until pulv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com