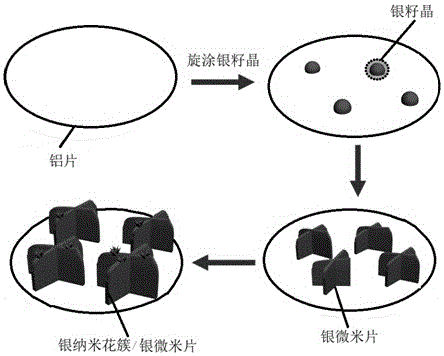

Preparation method and application of silver nano flower clusters/silver micro pieces of graded structures

A hierarchical structure, silver nanotechnology, applied in the field of analysis, can solve the problems that the structure uniformity of branches or flower clusters cannot be guaranteed, the density of silver nanosheets is small, and the silver nanostructure is not conducive to the detection of SERS technology, so as to achieve good SERS signal uniformity Reproducibility and repeatability, the effect of strong surface-enhanced Raman scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

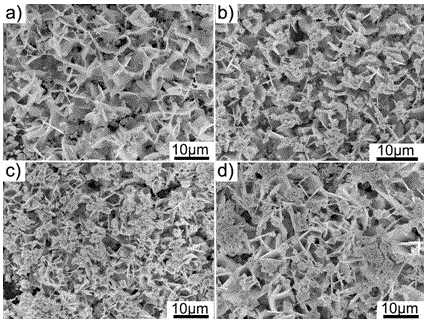

Examples

Embodiment 1

[0027] (1) Pretreatment of aluminum flakes: Cut the aluminum flakes into circular pieces with a diameter of 3 cm, first ultrasonically clean them in acetone for 40 minutes, then wash them several times with distilled water; then ultrasonically clean them in ethanol for 40 minutes, and then wash them with distilled water Several times, a clean aluminum sheet is obtained.

[0028] (2) Preparation of silver seed crystals: configure 5×10 -4 M Sodium borohydride (NaBH 4 ) solution, stand for 2 hours before use; take 0.005 g of silver nitrate and 0.04 g of PVP into 80 mL of deionized water, stir until completely dissolved; take 20 mL of 5×10 -4 M NaBH 4 The solution was quickly added to the mixed solution of silver nitrate and PVP, stirred at 800rpm for 10 minutes, and then left to stand for 24 hours to obtain silver seed crystals.

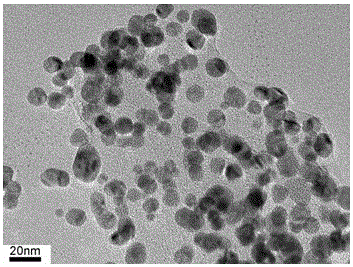

[0029] Such as figure 2 It can be seen that the size of the seed crystal is relatively uniform, and the average diameter is about 15nm.

[0030...

Embodiment 2

[0042] (1) Pretreatment of aluminum flakes: cut the aluminum flakes into circular slices with a diameter of 5 cm, first ultrasonically clean them in acetone and then wash them with distilled water for 3 times; then wash them with distilled water for 5 times after ultrasonic cleaning in ethanol, Clean aluminum flakes.

[0043] (2) Preparation of silver seed crystals: the concentration is 5×10 in an ice-water bath -4 Sodium borohydride solution of M (NaBH 4 ), stand still for 2 hours; get 0.005 grams of silver nitrate and 0.03 grams of PVP into deionized water, stir until completely dissolved; then quickly add sodium borohydride solution, so that the mass ratio of sodium borohydride to silver nitrate is 0.5:13, then stirred at 800 rpm for 10 minutes, and stood still for 24 hours to obtain silver seed crystals.

[0044] (3) Spin coating: drop 200 µL of silver seed crystal colloidal solution onto an aluminum sheet fixed on a spin coater, spin coat at a speed of 1000 rpm for 3 m...

Embodiment 3

[0048] (1) Pretreatment of aluminum flakes: cut the aluminum flakes into circular slices with a diameter of 4 cm, first ultrasonically clean them in acetone and then wash them with distilled water for 5 times; then ultrasonically clean them in ethanol and wash them with distilled water for 4 times, Clean aluminum flakes.

[0049] (2) Preparation of silver seed crystals: the concentration is 5×10 in an ice-water bath -4 Sodium borohydride solution of M (NaBH 4 ), stand still for 2 hours; get 0.005 gram of silver nitrate and 0.1 gram of PVP into deionized water, stir until completely dissolved; then quickly add sodium borohydride solution, so that the mass ratio of sodium borohydride to silver nitrate is 2:13, then stirred at 800rpm for 10 minutes, and left to stand for 24 hours to obtain silver seed crystals.

[0050] (3) Spin coating: drop 300 µL of silver seed crystal colloidal solution onto an aluminum sheet fixed on a spin coater, spin coat at a speed of 1500 rpm for 5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Excitation wavelength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com