Preparation method and application of lignin-based hierarchical-pore carbon material

A lignin-based, multi-level porous technology is applied in the field of preparation of lignin-based hierarchical porous carbon materials, can solve problems such as environmental impact, environmental pollution, etc., and achieves easy control of operation, abundant sources, and simple and feasible preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

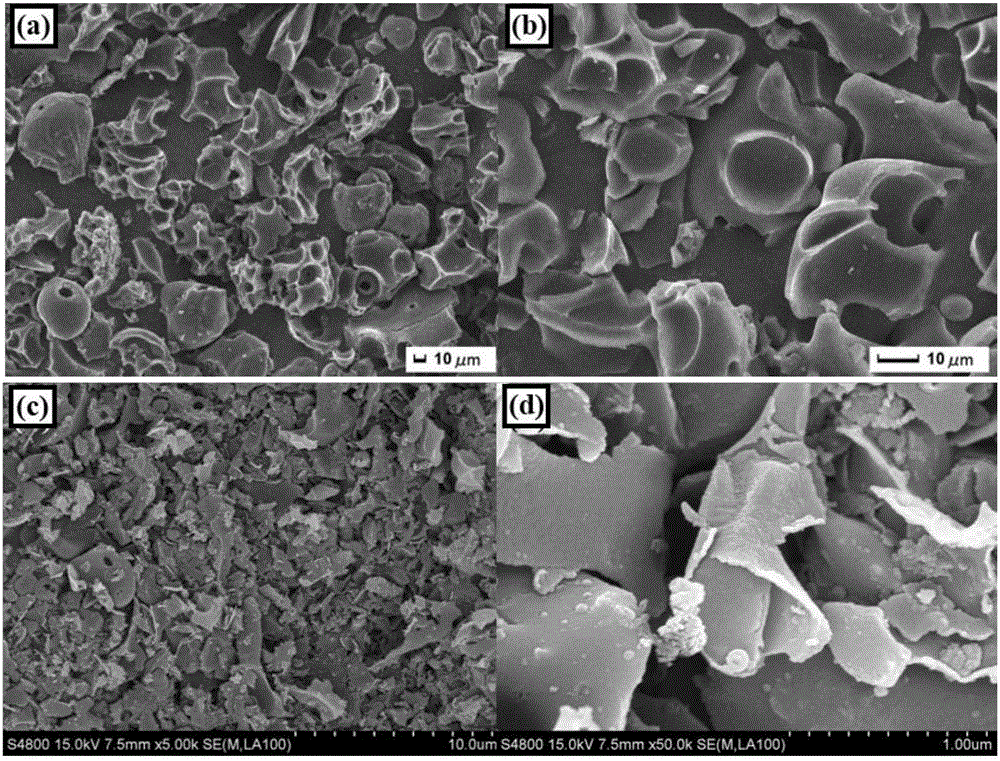

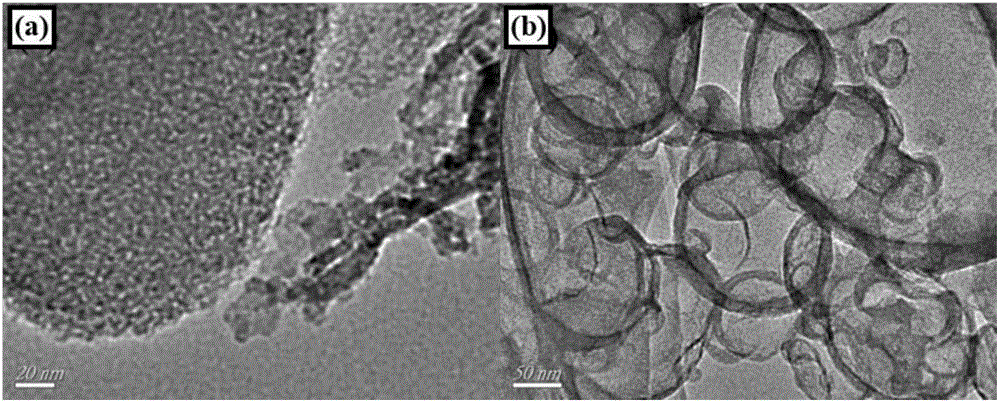

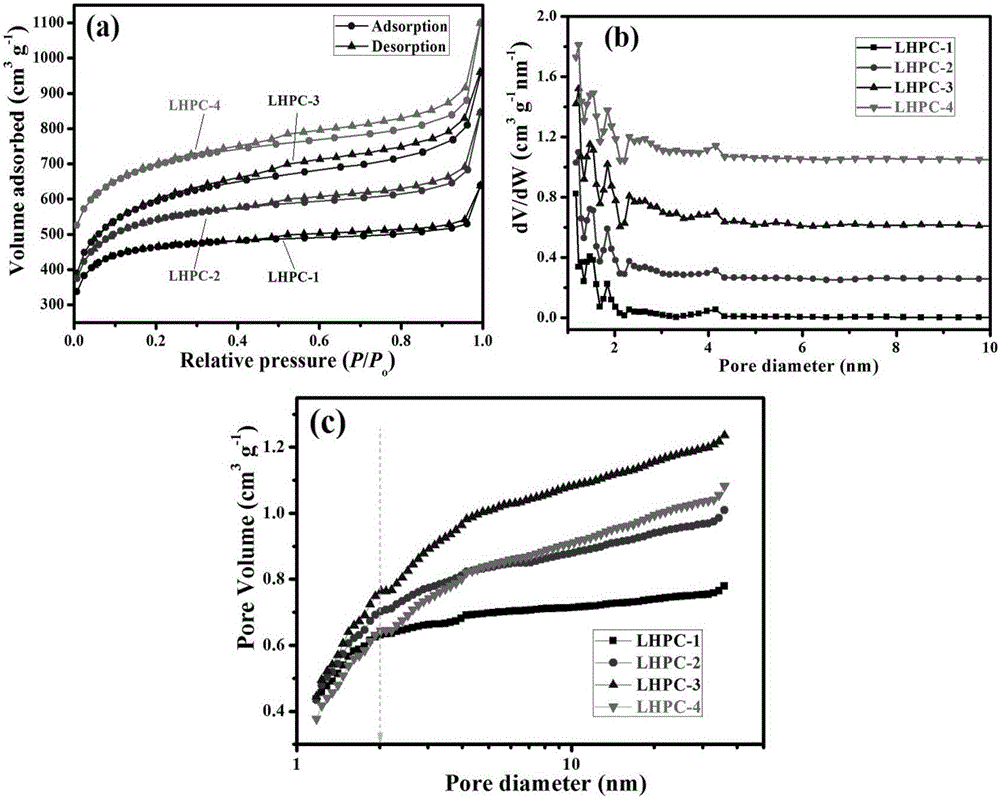

[0030] Fully mix potassium hydroxide and sodium lignosulfonate according to a certain mass ratio, the mass ratios are 0:1, 1:1, 2:1, 3:1 and 4:1, and then add it into the nickel pot, under nitrogen protection Under the conditions of carbonization and activation in a tube furnace, the temperature is 850°C, the heating rate is 5°C / min, and the temperature is maintained for 1h. Activated product with 0.5mol L -1 Soak in hydrochloric acid to remove impurities, vacuum filter, wash with deionized water until neutral, and dry to obtain lignin-based hierarchical porous carbon materials, which are sequentially marked as LHPC-0, LHPC-1, LHPC-2, LHPC-3, LHPC- 4.

[0031] Table 1 shows the pore structure parameters of LHPC-x. S of LHPC-1, LHPC-2, LHPC-3 and LHPC-4 BET 1759, 2001, 2235 and 1876m respectively 2 g -1 . As the amount of KOH increases, the specific surface area of the carbon material LHPC increases significantly, but the specific surface area of LHPC-4 decreases inst...

Embodiment 2

[0041] Fully mix potassium hydroxide and sodium lignosulfonate according to a certain mass ratio, the mass ratios are 0:1, 1:1, 2:1, 3:1 and 4:1, and then add it into the nickel pot, under nitrogen protection Under the conditions of carbonization and activation in a tube furnace, the temperature is 850°C, the heating rate is 3°C / min, and the temperature is maintained for 1h. Activated product with 1mol L -1 Soak in hydrochloric acid to remove impurities, vacuum filter, wash with deionized water until neutral, and dry to obtain lignin-based hierarchical porous carbon materials, which are sequentially marked as LHPC-0, LHPC-1, LHPC-2, LHPC-3, LHPC- 4.

Embodiment 3

[0043] Fully mix potassium hydroxide and sodium lignosulfonate according to a certain mass ratio, the mass ratios are 0:1, 1:1, 2:1, 3:1 and 4:1, and then add it into the nickel pot, under nitrogen protection Under the conditions of carbonization and activation in a tube furnace, the temperature is 850°C, the heating rate is 7°C / min, and the temperature is maintained for 1h. Activated product with 1.2mol L -1 Soak in hydrochloric acid to remove impurities, vacuum filter, wash with deionized water until neutral, and dry to obtain lignin-based hierarchical porous carbon materials, which are sequentially marked as LHPC-0, LHPC-1, LHPC-2, LHPC-3, LHPC- 4.

[0044] 2. In order to clarify the technical scheme and technical purpose of the present invention, the present invention will be further described below in conjunction with specific implementation examples:

[0045] In the present invention, the adsorption performance evaluation in the specific embodiment is carried out accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com