Submicron-order boron carbide powder and preparation method and application thereof

A sub-micron boron carbide powder technology, which is applied in chemical instruments and methods, offensive equipment, protective equipment, etc., can solve the problems of high cost and low production efficiency, reduce energy consumption, increase production efficiency, and reduce dust production. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation

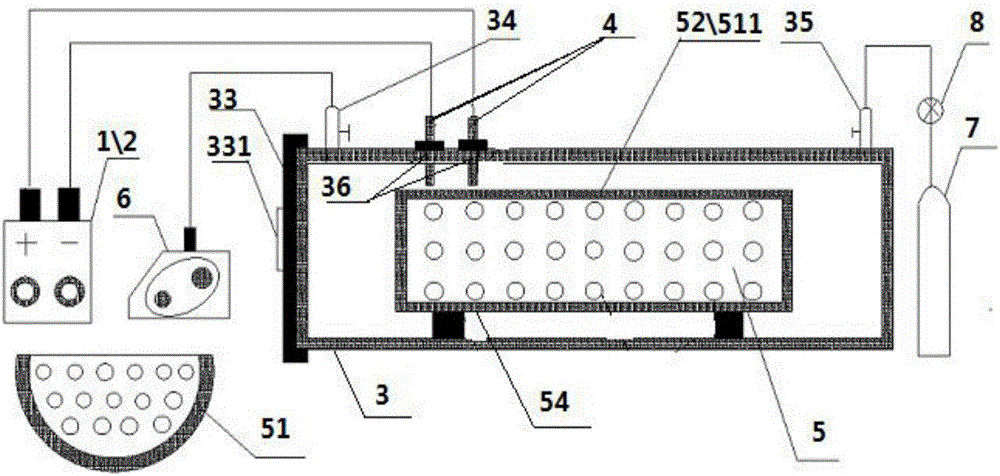

[0038] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

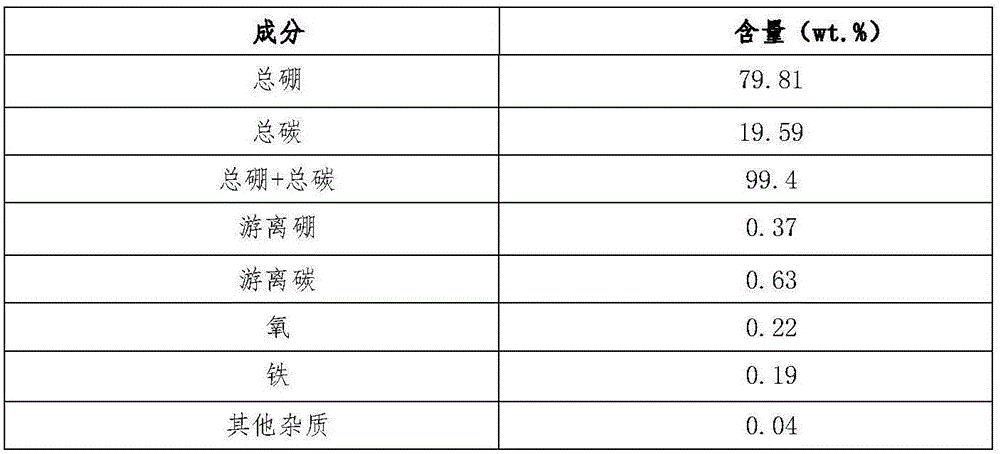

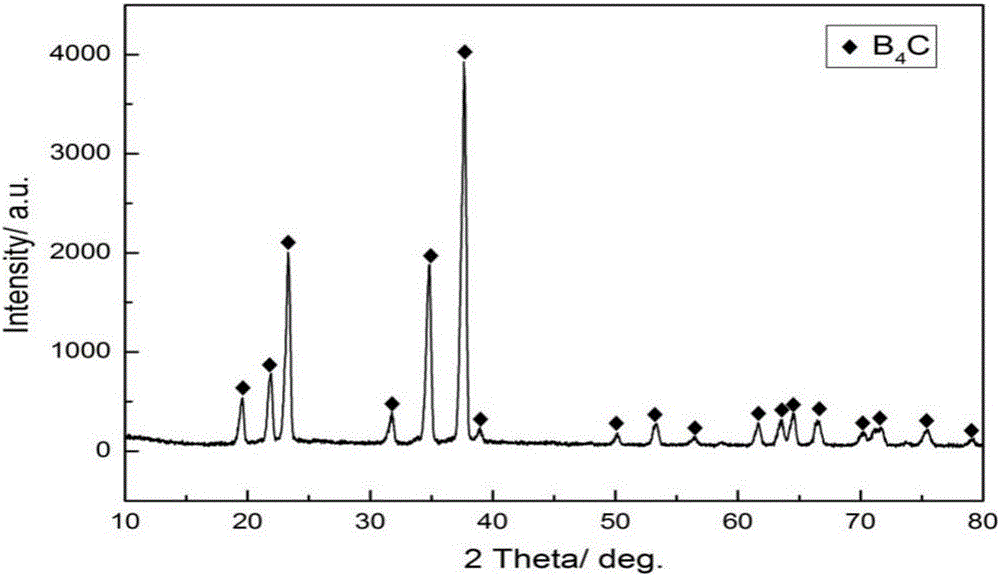

[0039] The present invention provides a boron carbide powder with a particle size of submicron (100 μm) and a synthesis method thereof. The following examples are only used to describe the present invention in detail, and do not limit the protection scope of the invention in any way. The inventive method is:

[0040] Step 1 Prepare raw materials for preliminary mixing

[0041] The present invention takes B 2 o 3 , nanometer carbon black is boron source and carbon source, is reducing agent with metal magnesium, and diboron trioxide (B 2 o 3 ), nanometer carbon black (C) and metal magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com