A kind of method that takes carnallite as raw material to produce potassium sulfate

A carnallite and potassium sulfate technology, which is applied in the preparation of sulfate/bisulfate, solid separation, flotation, etc., can solve the high mineral composition requirements of potassium mixed salt ore, the recycling of transformation mother liquor, and the large amount of discharged mother liquor to avoid energy consumption and potassium salt loss, improve utilization methods, and achieve high potassium yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

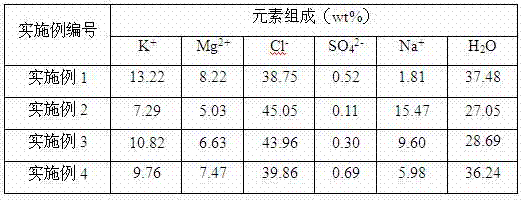

Embodiment 1

[0036] (1) Batching conversion: mix the chloride-type Yantian carnallite ore 1, sodium sulfate and water according to the ratio of 1:0.5:0.4 by weight, and convert it for 2.0 hours at 35°C to obtain langbeinite slurry ;

[0037] (2) langbeinite flotation: add langbeinite and sodium chloride co-saturated mother liquor in step (1) obtained lenbeinite slurry (the mass concentration of each element is: K + : 3.01wt%, Mg 2+ : 4.68wt%, Cl - : 15.80wt%, SO 4 2- : 8.07wt%, the rest is water) adjust the slurry mass concentration to 26wt%, and add 150g sodium dodecylsulfonate / ton of langbeinite slurry, and adopt a rough and sweep flotation process for flotation separation , to obtain soft potassium concentrate and mother liquor I; wherein, the mass percentage of each element in soft potassium concentrate is: K + : 16.97%, Mg 2+ : 5.81%, Cl - : 6.24%, SO 4 2- : 39.14%, the remainder is water; the mass concentration of each element in mother liquor Ⅰ is: K + : 2.62wt%, Mg 2+ : ...

Embodiment 2

[0042] (1) Batching conversion: mix the chloride-type Yantian carnallite ore 2, sodium sulfate with the forced evaporation of the mother liquor II obtained in step (3) of Example 1 and mix the ingredients according to the ratio of 1:1.05:1.64 by weight, Transform at 30°C for 1.5 hours to obtain langbeinite slurry;

[0043] (2) langbeinite flotation: Add the mother liquor I obtained in step (2) of Example 1 to the slurry of langbeinite obtained in step (1) as the slurry mixing mother liquor to adjust the mass concentration of the slurry to 28wt%, and add 120g Sodium dodecylsulfonate / tonne langbeinite slurry is separated by flotation by a rough and sweep flotation process to obtain soft potassium concentrate and mother liquor I; wherein, the mass percentage of each element of soft potassium concentrate is :K + : 15.92%, Mg 2+ : 6.50%, Cl - : 7.26%, SO 4 2- : 39.15%, the remainder is water; the mass concentration of each element in mother liquor Ⅰ is: K + : 2.85wt%, Mg 2+ ...

Embodiment 3

[0048] (1) Batching conversion: mix the chloride-type Yantian carnallite ore 3, sodium sulfate and the system slurry obtained from the mother liquor II obtained in step (3) of Example 2 by forced evaporation according to the weight ratio of 1:1.48:2.05, Transform at 35°C for 2.5 hours to obtain langbeinite slurry;

[0049] (2) langbeinite flotation: Add the mother liquor I obtained in step (2) of Example 2 to the langbeinite slurry obtained in step (1) as the pulping mother liquor to adjust the mass concentration of the slurry to 30wt%, and add 240g Sodium dodecyl sulfonate / tonne langbeinite slurry, using a roughing process for flotation separation, to obtain soft potash concentrate and mother liquor I; wherein, the mass percentage of each element of soft potash concentrate is: K + : 16.31%, Mg 2+ : 6.35%, Cl - : 5.61%, SO 4 2- : 40.51%, the remainder is water; the mass concentration of each element in mother liquor Ⅰ is: K + : 2.72wt%, Mg 2+ : 4.54wt%, Cl - : 15.33wt%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com