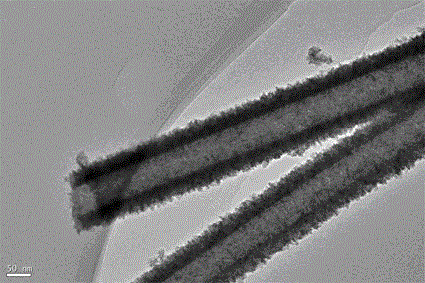

Method for growing porous tin dioxide nano-tubes on electric conduction substrate

A conductive substrate, tin dioxide technology, applied in tin oxide, nanotechnology, nanotechnology, etc., can solve problems such as environmental pollution, cumbersome experimental steps, and increase in preparation costs, and achieve wide application prospects, large specific surface area, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further illustrate the method for preparing one-dimensional porous tin dioxide nanotubes, this embodiment is implemented according to the technical solution of the present invention, and specific implementation methods are given:

[0025] a. The first step is to prepare ZnO nanorods as in situ sacrificial templates.

[0026] First, ultrasonically clean FTO with acetone, ethanol, and ultrapure water for 10 min each, and place it obliquely into the polytetrafluoroethylene lining of the autoclave with the conductive side facing down, weigh 0.0658 g of zinc acetate, and dissolve it into 10 mL of ultrapure water, and the resulting solution was stirred at room temperature for 5 min; weighed 0.0421 g of hexamethylenetetramine, dissolved it in 10 mL of ultrapure water, stirred at room temperature for 5 min, and then transferred it to the Zinc acetate solution and stirred at room temperature for 10 min; finally, transfer the obtained mixed solution to an autoclave, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com