Offshore platform sewage treatment method

An offshore platform and treatment method technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem that COD is difficult to meet the pollutant discharge concentration limit and limit requirements, and can resist hydraulic load. Problems such as poor capacity and unstable treatment effect can reduce the amount of subsequent treatment, occupy less floor space, and reduce the oil content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

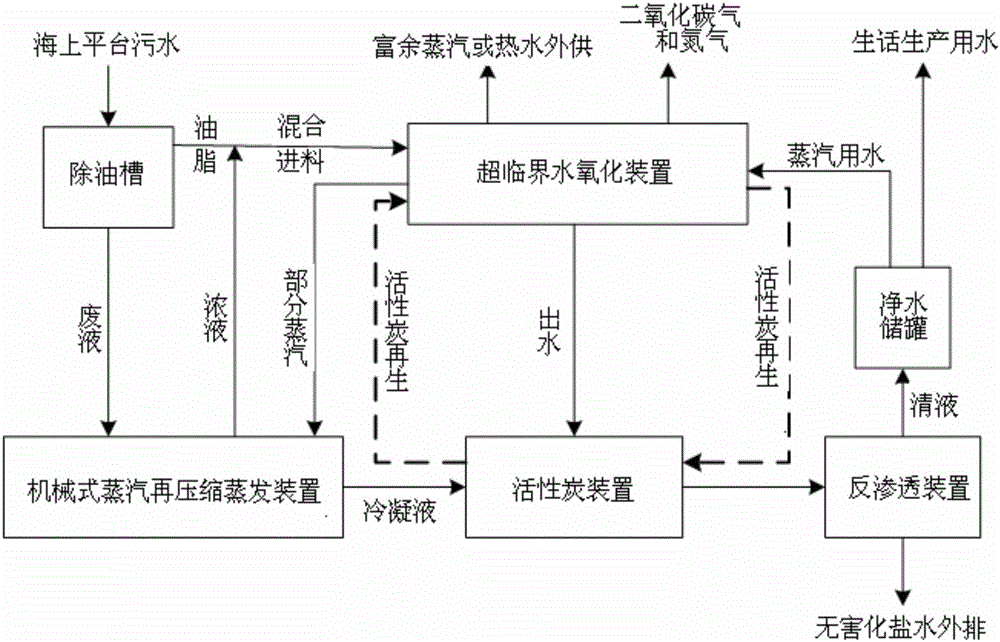

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0025] The process flow of the invented treatment method for offshore platform sewage is as follows figure 1 As shown, a method for treating sewage on an offshore platform includes an oil removal tank, a mechanical vapor recompression evaporation device, an activated carbon device, a reverse osmosis device, a clean water storage tank and a supercritical water oxidation device. The method operates as follows:

[0026] 1. First, degreasing treatment is carried out on the sewage on the offshore platform through the degreasing tank. The upper layer skims the grease, and the lower layer waste liquid enters the mechanical steam recompression evaporation device for concentration. system.

[0027] 2. The condensate evaporated from the mechanical vapor recompression evaporation device and the effluent treated by the supercritical water oxidation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com