High-strength abrasion-resistant compound castable

A high-temperature wear-resistant and castable technology, which is applied in the field of refractory materials, can solve the problems of hidden dangers in the safety production of molten salt furnaces, poor fluidity of castables, and low bonding strength, so as to improve oxidation resistance, continuous and reliable construction performance, and Effect of improving thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

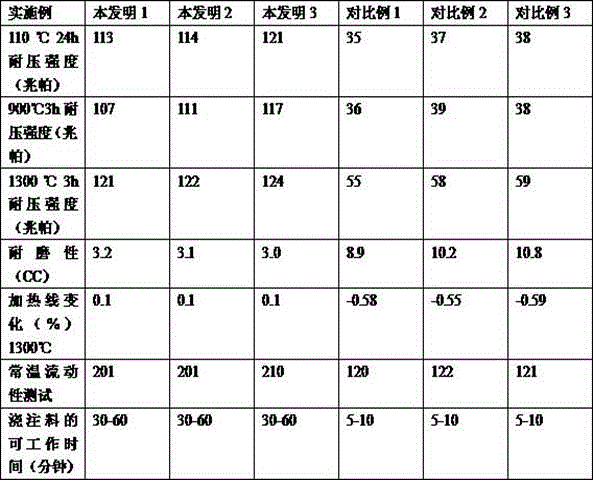

Examples

Embodiment 1

[0067] Example 1, 50 parts of 12-5mm chrome corundum, 10 parts of 5-3mm silicon carbide, 5 parts of 3-1mm calcium hexaaluminate, 4 parts of 1-0mm andalusite, 1 part of 200 mesh Yongji clay, 325 mesh silicon nitride 10 parts of powder, 5 parts of 325 mesh cutting powder, 5 parts of zinc silicate powder, 3 parts of 800 mesh andalusite powder, 1 part of 1000 mesh iron-zinc spinel powder, 3 parts of 1000 mesh zinc oxide powder, 3 parts of CA60 cement , plus the additive REFPAC ® 100 1 part, plus fluidity improving additive Peramin ® 0.1 part of AL 200, plus 0.1 part of nanocellulose.

Embodiment 2

[0068] Example 2, 50 parts of 12-5mm chrome corundum, 7 parts of 5-3mm silicon carbide, 5 parts of 3-1mm calcium hexaaluminate, 3 parts of 1-0mm andalusite, 1 part of 200 mesh Yongji clay, 325 mesh silicon nitride 8 parts of powder, 6 parts of 325 mesh cutting powder, 5 parts of zinc silicate zirconium powder, 3 parts of 800 mesh andalusite powder, 1 part of 1000 mesh iron-zinc spinel powder, 5 parts of 1000 mesh zinc oxide powder, 6 parts of CA60 cement , plus the additive REFPAC ® 100 1 part, plus fluidity improving additive Peramin ® 0.1 part of AL 200, plus 0.1 part of nanocellulose.

Embodiment 3

[0069] Example 3, 55 parts of 12-5mm chrome corundum, 8 parts of 5-3mm silicon carbide, 5 parts of 3-1mm calcium hexaaluminate, 3 parts of 1-0mm andalusite, 2 parts of 200 mesh Yongji clay, 325 mesh silicon nitride 9 parts of powder, 3 parts of 325 mesh cutting powder, 3 parts of zinc silicate powder, 4 parts of 800 mesh andalusite powder, 1 part of 1000 mesh iron zinc spinel powder, 3 parts of 1000 mesh zinc oxide powder, 4 parts of CA60 cement , plus the additive REFPAC ® 100 1 part, plus fluidity improving additive Peramin ® 0.1 part of AL 200, plus 0.1 part of nanocellulose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com