Ultraviolet (UV) light LED (light emitting diode) lamp bead packaging glue and preparation method thereof

A technology of LED lamp beads and ultraviolet light, applied in the direction of adhesives, adhesive additives, electrical components, etc., can solve the problems of short service life, long response time, low heat, etc., and achieve good adhesion, reasonable formula, and high transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

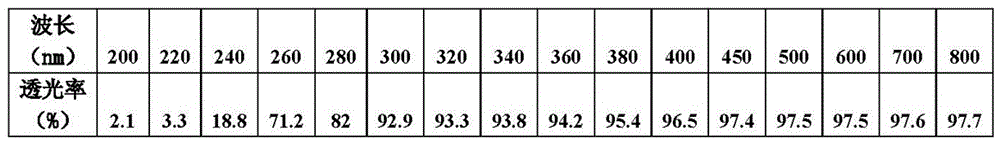

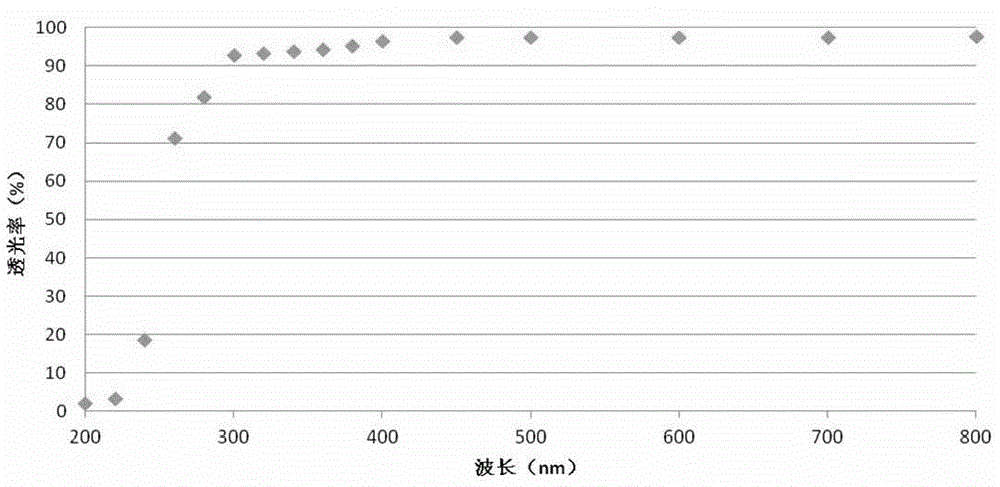

Embodiment 1

[0033] Embodiment 1, a kind of glue for packaging ultraviolet LED lamp beads provided in this embodiment, includes the following components in parts by weight: 10 parts of vinyl-terminated organopolysiloxane, 60 parts of liquid vinyl MQ silicone resin, linear 10 parts of methyl hydrogen polysiloxane, 0.5 parts of platinum complex catalyst, 0.2 parts of inhibitor, and 2 parts of tackifier.

[0034] Preferably, the vinyl-terminated organopolysiloxane is preferably a linear organopolysiloxane whose two ends of the molecule are terminated with vinyl groups, and the viscosity is 1000-50000 mpa.s / 25°C. The linear methylhydrogenpolysiloxane is preferably a linear methylhydrogenpolysiloxane containing two or more hydrogen atoms in the molecule. The platinum complex catalyst is preferably a Castel platinum catalyst. The inhibitor is preferably one or more of acetylenic alcohols or polyvinylsiloxanes. The tackifier is preferably γ-(2,3-epoxypropoxy)propyltrimethoxysilane, γ-methacrylo...

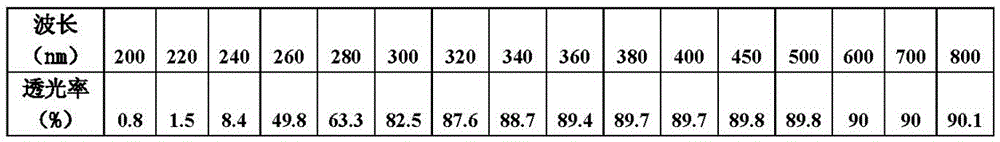

Embodiment 2

[0039] Example 2, a kind of glue for packaging ultraviolet LED lamp beads and its preparation method provided in this example, it is basically the same as Example 1, the difference is that its component weight ratio is different: terminal vinyl organic 30 parts of polysiloxane, 80 parts of liquid vinyl MQ silicone resin, 18 parts of linear methyl hydrogen polysiloxane, 0.1 part of platinum complex catalyst, 0.3 parts of inhibitor, and 5 parts of tackifier.

Embodiment 3

[0040] Example 3, a kind of glue for packaging ultraviolet LED lamp beads and its preparation method provided in this example, which is basically the same as Example 1, the difference is that its component weight ratio is different: vinyl-terminated organic 50 parts of polysiloxane, 50 parts of liquid vinyl MQ silicone resin, 2 parts of linear methyl hydrogen polysiloxane, 1 part of platinum complex catalyst, 0.03 parts of inhibitor, and 1 part of tackifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com