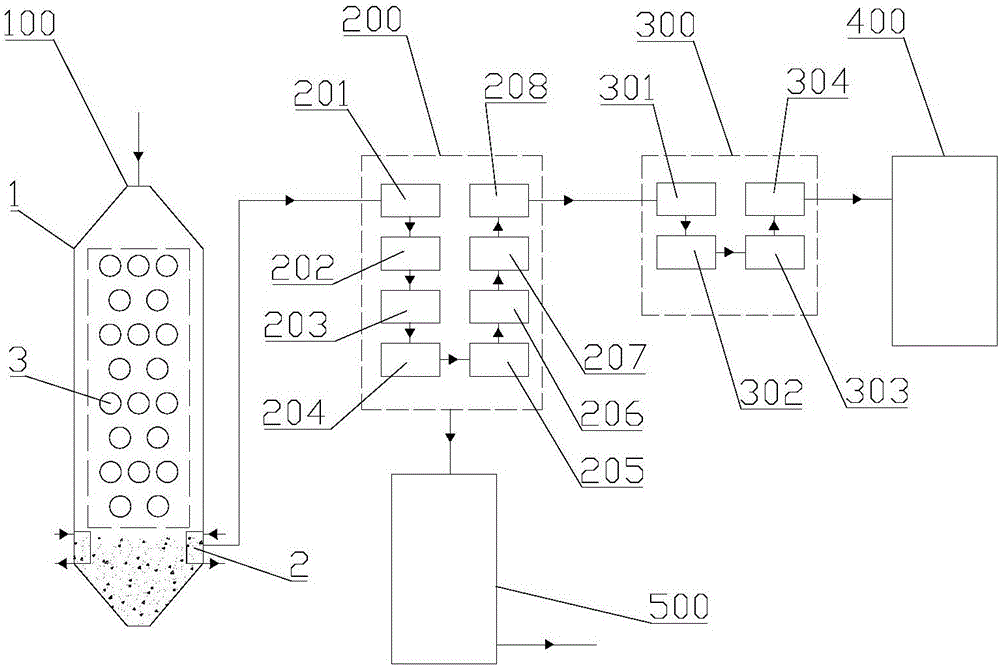

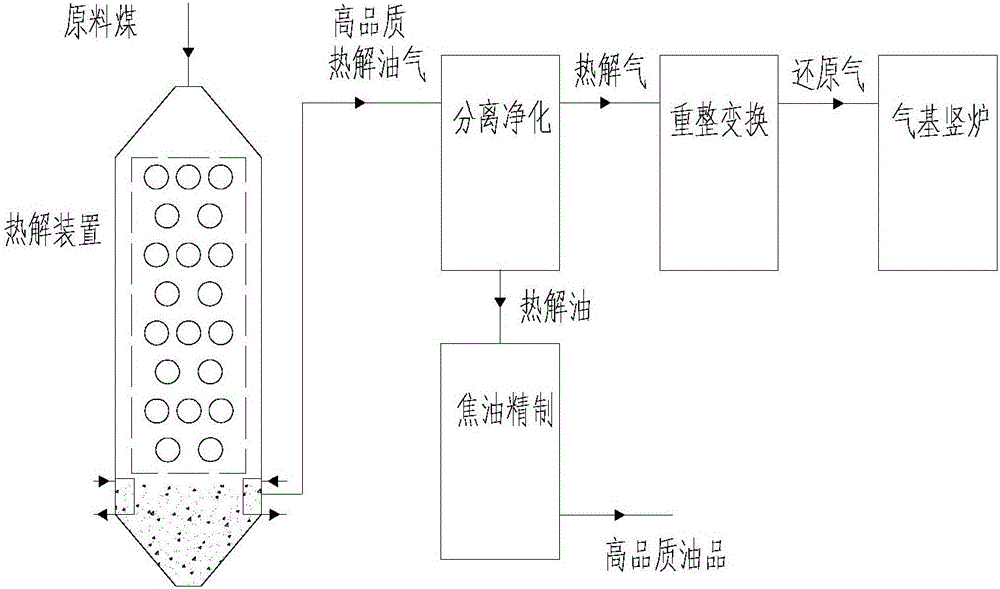

Pyrolysis device and gas-based shaft kiln combined system and method for treating coal

A technology of gas-based shaft furnace and pyrolysis of oil and gas, which is applied in the direction of shaft furnace, removal of gas pollutants, furnace, etc., can solve the problems of irregular dust shape, heavy tar components, large dust content, etc., and achieve Reduce the cost of pretreatment, low cost, reduce the effect of dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

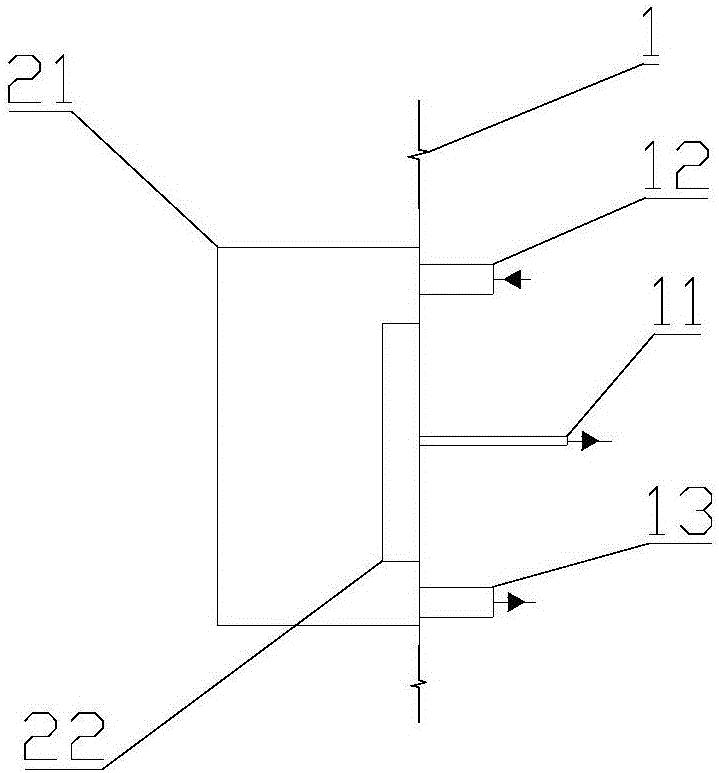

[0059] The raw coal is crushed to a particle size below 3mm, and sent to the combined system of the pyrolysis device and the gas-based shaft furnace. The temperature in the pyrolysis device is controlled at 900°C. The pyrolysis device is equipped with multi-layer heating radiant tubes and particle moving bed dust removal system. . The pyrolysis oil gas is continuously cracked by the action of the catalyst in the particle moving bed to obtain high-quality pyrolysis oil gas. After the high-quality pyrolysis oil and gas produced by the pyrolysis unit pass through the separation and purification system and the tar refining system, pyrolysis gas and high-quality oil can be obtained. The pyrolysis gas is processed by the reforming conversion system to obtain reducing gas, and the reducing gas directly enters the gas-based shaft furnace for production. The composition of the pyrolysis gas after the separation and purification system is shown in Table 1.

[0060] Table 1 Composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com