Multiphase Magnesium Rare Earth Nickel Hydrogen Storage Alloy and Its Application

A hydrogen storage alloy, nickel-based technology, applied in the field of hydrogen storage materials, can solve the problems of mismatched expansion ratio, unsatisfactory cycle performance, and increased alloy cost, and achieve good activity performance, good cycle stability, and ease of internal stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

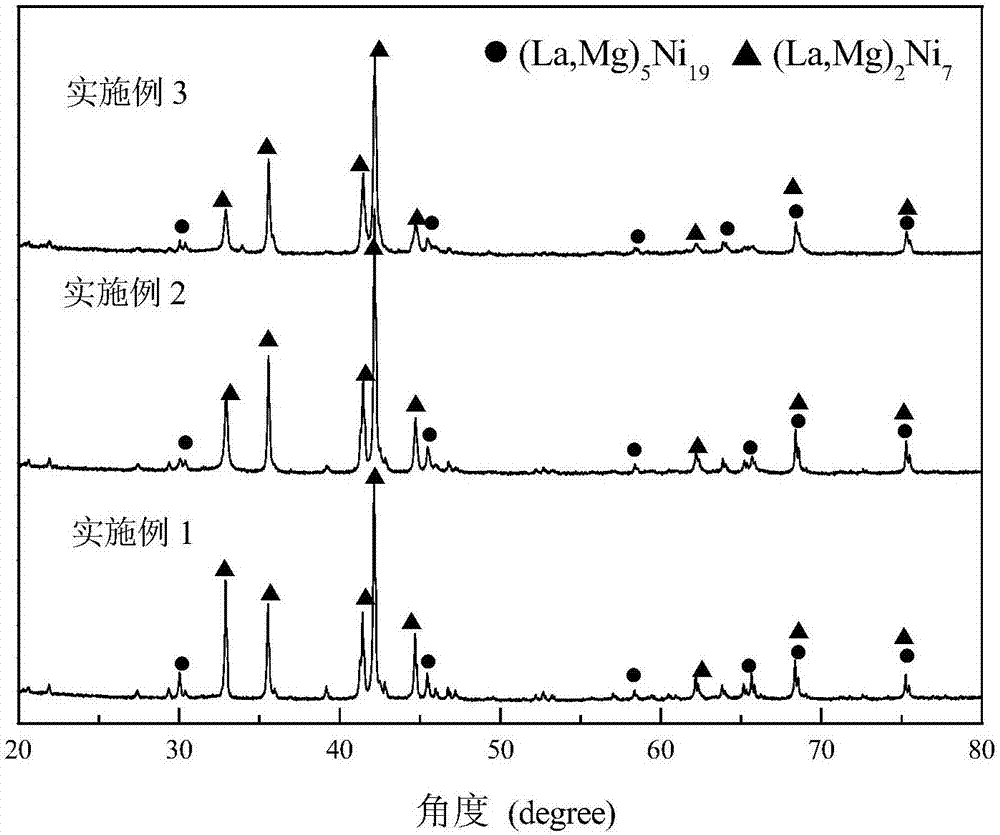

[0036] According to the designed chemical composition formula La 4 MgNi 17 Carry out batching, consider the loss of Mg, Mg excess 15wt%, take the La, Mg and Ni metal that purity is 99.9%, adopt medium-frequency induction melting of argon protection to prepare alloy, the alloy obtained is heat treated at 950 ℃ under argon protection, when When the temperature is lower than 500°C, the heating rate is 5°C / min, and then heated to 950°C at a heating rate of 2°C / min, and kept for 24 hours. The above-mentioned heat-treated alloy is naturally cooled in a protective atmosphere. Samples were subjected to X-ray analysis and Rietica software was used for refinement.

[0037] To measure the electrochemical performance of the alloy, the sample used for the test is the internal sample of the block alloy. The above-mentioned hydrogen storage alloy is mechanically pulverized, sieved with a sieve, and 0.15 grams of 200-400 mesh alloy powder and 0.75 grams of carbonyl nickel powder are taken. A...

Embodiment 2

[0042] Embodiment 2: chemical composition formula is La 3 SmMgNi 17.5 , the preparation method is the same as in Example 1.

[0043] Such as figure 1 Shown, the alloy La prepared in embodiment 2 3 SmMgNi 17.5 Middle A 5 B 19 Phase abundance is 8.34%, A 2 B 7 The phase abundance is 91.66%.

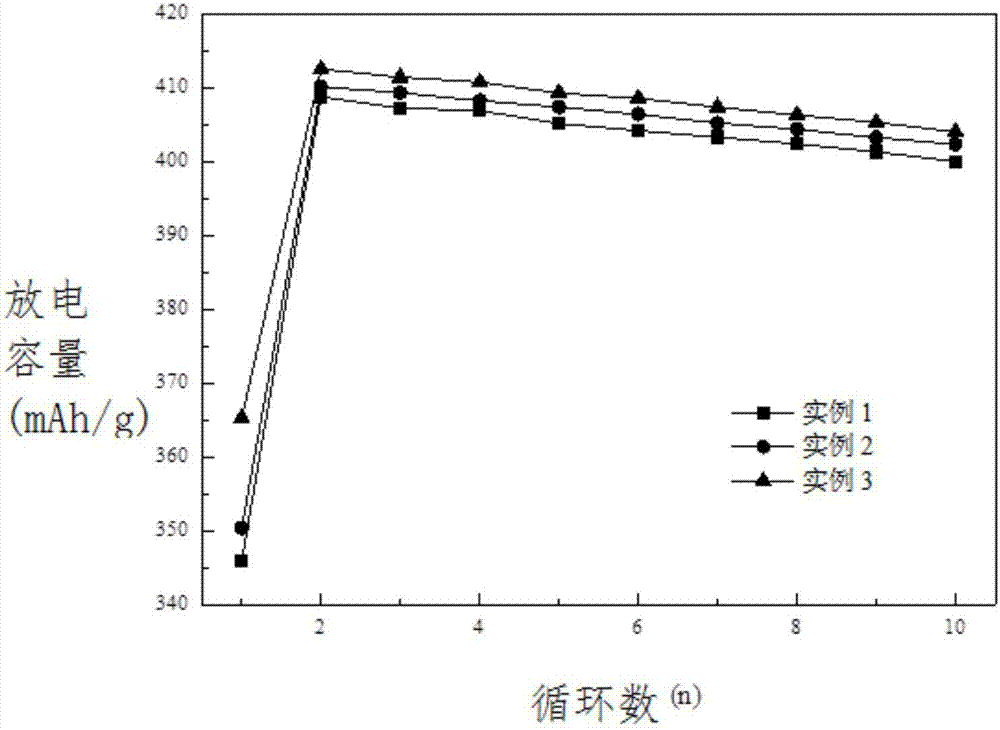

[0044] Such as figure 2 As shown, the La-Mg-Ni alloy prepared in Example 2 has good activation performance, and the maximum discharge capacity is 410.10mAh / g.

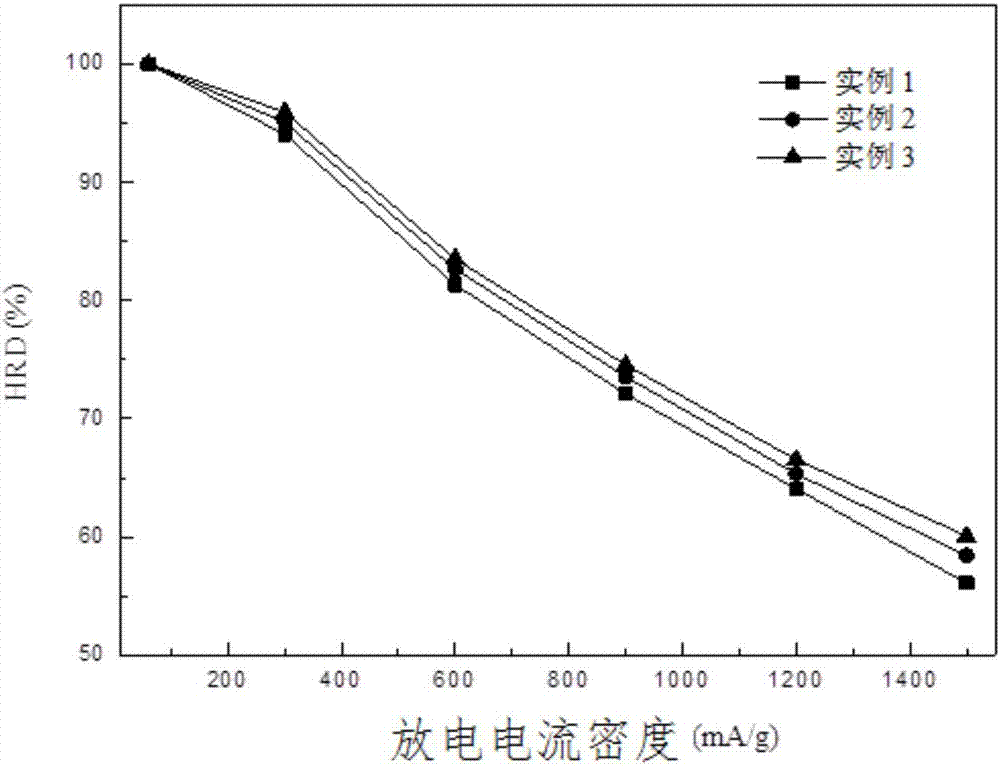

[0045] Such as image 3 Shown, the La-Mg-Ni series alloy that embodiment 2 prepares has the characteristic of high power, HRD 1500 (High-rate discharge performance at a discharge current density of 1500 mA / g) was 58.45%.

[0046] Such as Figure 4 Shown, the cycle stability of the La-Mg-Ni series alloy prepared in embodiment 2 is very good, S 200 (The capacity retention rate at 200 cycles of charge and discharge) was 95.00%, and the charge retention rate CR(36h)=93.2%.

Embodiment 3

[0047] Embodiment 3: chemical composition formula is La 4 MgNi 16.5 Co, the sample was kept at 900° C. for 24 hours after it came out of the furnace, and the rest were the same as in Example 1.

[0048] Such as figure 1 Shown, the alloy La prepared in embodiment 3 4 MgNi 16.5 A in Co 5 B 19 Phase abundance is 6.78%, A 2 B 7 The phase abundance is 93.22%.

[0049] Such as figure 2 As shown, the La-Mg-Ni alloy prepared in Example 3 has good activation performance, and the maximum discharge capacity is 412.48mAh / g.

[0050] Such as image 3 Shown, the La-Mg-Ni system A prepared in embodiment 3 2 B 7 type two-phase alloys are characterized by high power, HRD 1500 (High-rate discharge performance at a discharge current density of 1500 mA / g) was 60.10%.

[0051] Such as Figure 4 Shown, the cycle stability of the La-Mg-Ni series alloy prepared in embodiment 3 is very good, S 200 (The capacity retention rate at 200 cycles of charge and discharge) was 95.71%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com