A kind of yttrium aluminate composite crystal and preparation method thereof

A composite crystal, yttrium aluminate technology, used in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problems of demanding manufacturing equipment, uneven optical quality, large laser loss, etc., and achieve low cost and large size. Economical adaptability, simple effect of equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In a second aspect, an embodiment of the present invention provides a method for preparing the above-mentioned yttrium aluminate composite crystal, the method comprising the following steps:

[0038] Step 101, respectively activate the doped yttrium aluminate crystal and the yttrium aluminate crystal, so that the bonding surface of the doped yttrium aluminate crystal has hydrogen bond dangling bonds, and at the same time make the bonding surface of the yttrium aluminate crystal There are hydrogen and oxygen dangling bonds on the bonding surface of the doped yttrium aluminate crystal, or the bonding surface of the doped yttrium aluminate crystal is provided with hydrogen and oxygen dangling bonds, and at the same time, the bonding surface of the yttrium aluminate crystal is provided with hydrogen bonding dangling bonds.

[0039] Step 102 , pre-bonding the bonding surface of the yttrium aluminate crystal and the bonding surface of the doped yttrium aluminate crystal by mea...

Embodiment 1

[0055] The bonding surfaces of the doped yttrium aluminate crystal and the yttrium aluminate crystal are polished so that the respective bonding surfaces meet the bonding quality requirements. Then, soak the doped yttrium aluminate crystal in dilute nitric acid with a mass concentration of 5% for 30 minutes, so that the bonding surface of the doped yttrium aluminate crystal has hydrogen bond dangling bonds, and the yttrium aluminate crystal is placed on the mass concentration Soak in ethanol solution of 5% NaOH for 30 minutes, so that the bonding surface of the yttrium aluminate crystal has hydrogen-oxygen dangling bonds. Then the above-mentioned crystals were taken out, rinsed with deionized water and wiped clean. Aligning the bonded facets of the yttrium aluminate crystal with the bonded facets of the doped yttrium aluminate crystal by the direct bonding technique while using a strain gauge to observe the stress profile of the bonded crystal to achieve high-precision axial m...

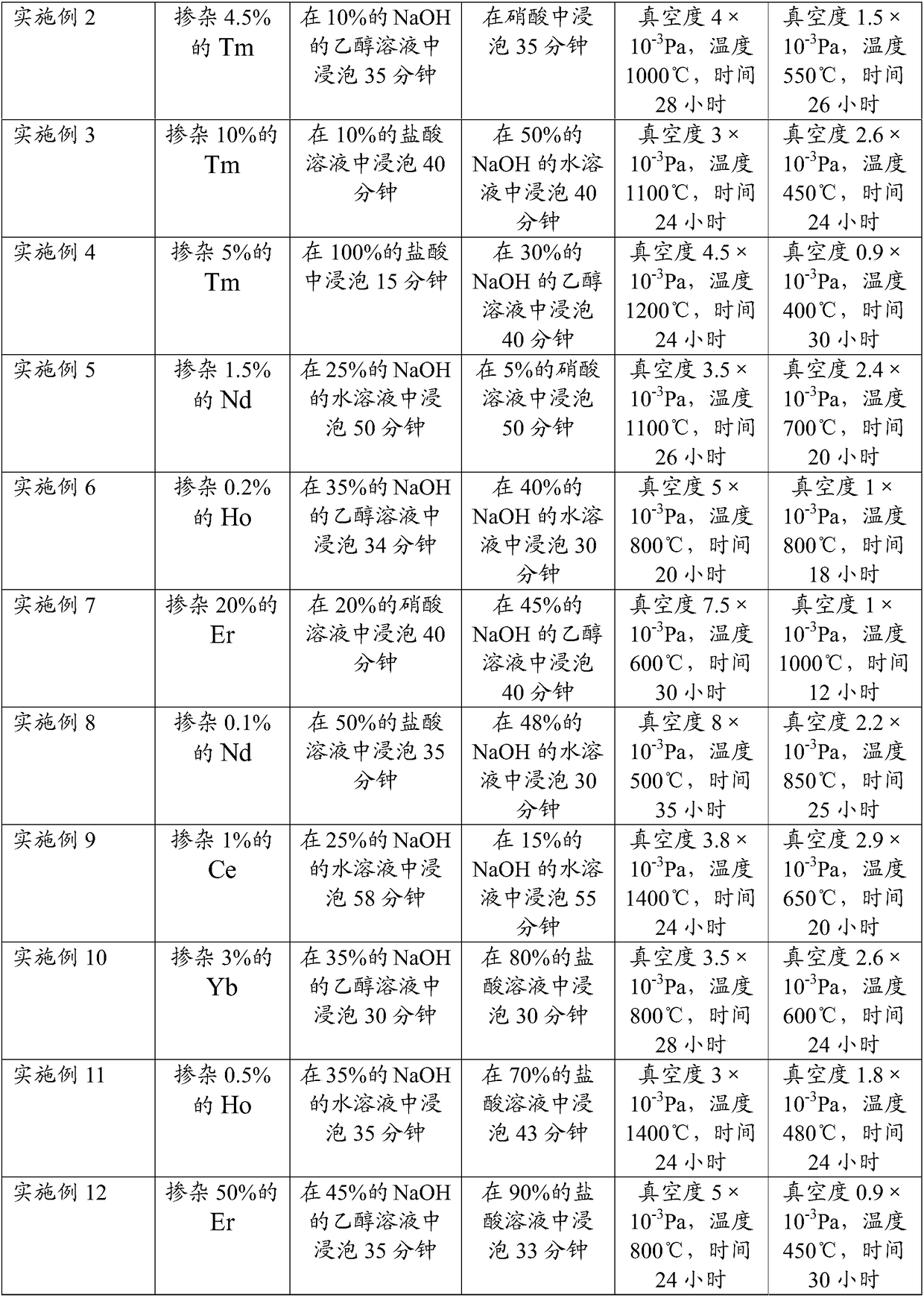

Embodiment 2-12

[0058] The operation steps of the following examples are basically the same as those of Example 1. Please refer to Table 1 for the differences, where the mass of active ions doped in the column of doped yttrium aluminate crystal specifications in Table 1 is measured in atomic concentration. In the two columns of doped yttrium aluminate crystal activation treatment and yttrium aluminate crystal activation treatment, the quality of the alkaline washing solution and the pickling washing solution is measured by mass concentration.

[0059] Table 1

[0060]

[0061]

[0062] Under white light or helium-neon laser, the bonding surfaces of the yttrium aluminate composite crystals prepared in the above examples were observed with naked eyes, and there were no bubbles, no cracks, and no scattering. It can be seen that the yttrium aluminate composite crystal provided by the embodiment of the present invention has uniform optical quality at the bonding surface, and there is no inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com