Method for measuring content of barium in barium nitrate for fireworks and crackers

A technology for fireworks and firecrackers and barium nitrate, which is applied in the field of analysis and testing, can solve the problems of insufficient operation proficiency, complicated operation steps, error in measurement results, etc., and achieves the effects of low labor intensity, simple operation, and short detection period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

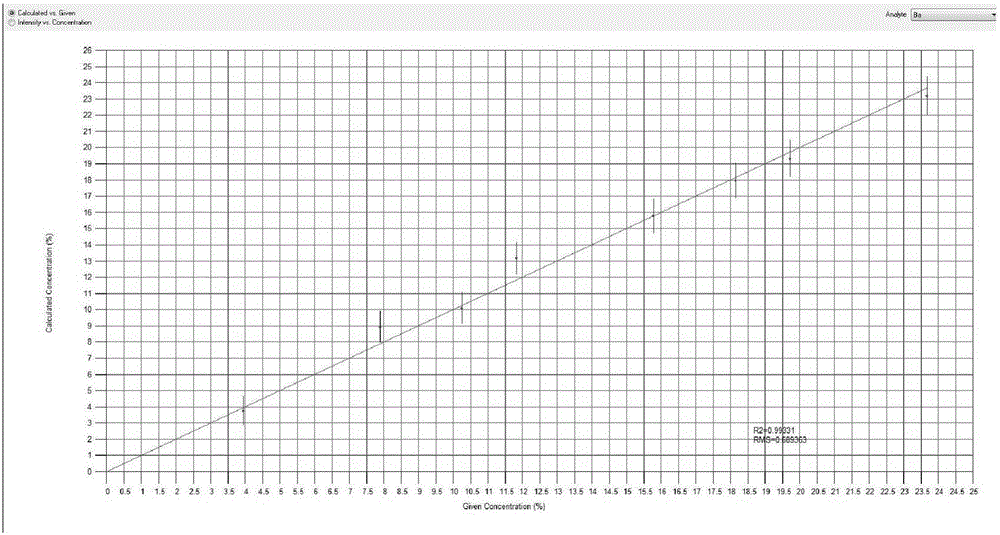

[0033] Embodiment 1: Make calibration curve

[0034] 1) Prepare several parts of barium working solution (the mass concentration of Ba in the obtained barium nitrate working solution is required to be 0.15g / L~0.73g / L):

[0035] The specific preparation method is as follows:

[0036] Accurately weigh 3.0g of high-purity barium nitrate (accurate to 0.1mg), put it in a 300mL beaker, add 100mL~150mL of water, place the beaker on an electric furnace and heat for 10min~15min, filter it with filter paper while it is hot, and filter the filtrate to a capacity of 500mL bottle, add 10mL ~ 30mL nitric acid, after the solution in the volumetric flask is cooled to room temperature, add water to make it up to the mark; wherein, the nitric acid is HNO 3 Nitric acid with a content of 10% to 30% by mass.

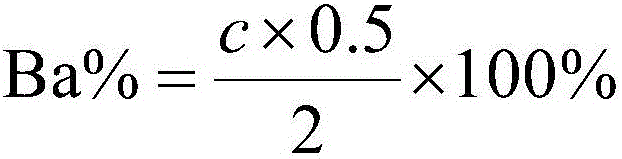

[0037] Prepare 8 parts of barium nitrate working solution: pipette 5mL, 10mL, 13mL, 15mL, 20mL, 23mL, 25mL and 30mL of the above-mentioned barium nitrate working solution after constant vo...

Embodiment 2

[0048] Embodiment 2: adopt method of the present invention to measure the control experiment of barium nitrate reference substance and barium standard solution

[0049] Test with barium nitrate reference material and barium standard solution listed in table 3, wherein the barium nominal content of barium nitrate reference material and barium standard solution is as shown in table 3; When adopting the method for the present invention to measure, barium nitrate The reference substance is prepared in the following way to prepare the sample solution, and then the barium content is determined.

[0050] 1) Preparation of sample solution:

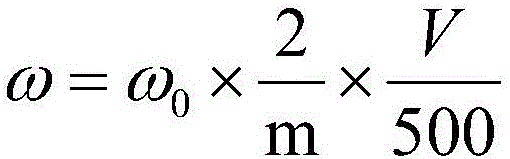

[0051] Use the reference substance No. 1 as the sample to prepare the sample solution, weigh 3 parts of 0.4g ~ 0.6g sample, and the weighing is accurate to 0.1mg, put the first sample in a 300mL beaker, add 100mL ~ 150mL of water , put the beaker on the electric furnace and heat it for 10min~15min, filter it with filter paper while it is hot, fil...

Embodiment 3

[0063] Embodiment 3: Adopt the precision test of the detection result of barium nitrate reference substance by method of the present invention

[0064] In this embodiment, three barium nitrate reference substances for fireworks and firecrackers with different main contents were taken as samples for testing, and the numbers were 4, 5 and 6 respectively.

[0065] 1) Preparation of sample solution:

[0066] Use the reference substance No. 4 as the sample to prepare the sample solution, weigh 4 parts of 0.4g ~ 0.6g sample, and weigh it accurately to 0.1mg, put the first sample in a 300mL beaker, add 100mL ~ 150mL of water , put the beaker on the electric furnace and heat it for 10min~15min, filter it with filter paper while it is hot, filter the filtrate into a 500mL volumetric flask, add 10mL~30mL of nitric acid with a concentration of 10%~30%, and add water after the solution in the volumetric flask cools to room temperature Dilute to the mark to obtain the first sample solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com