Catalyst for electrochemically synthesizing ammonia and preparing method thereof

A technology for synthesizing ammonia and catalysts, applied in physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc. The effect of reducing consumption and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

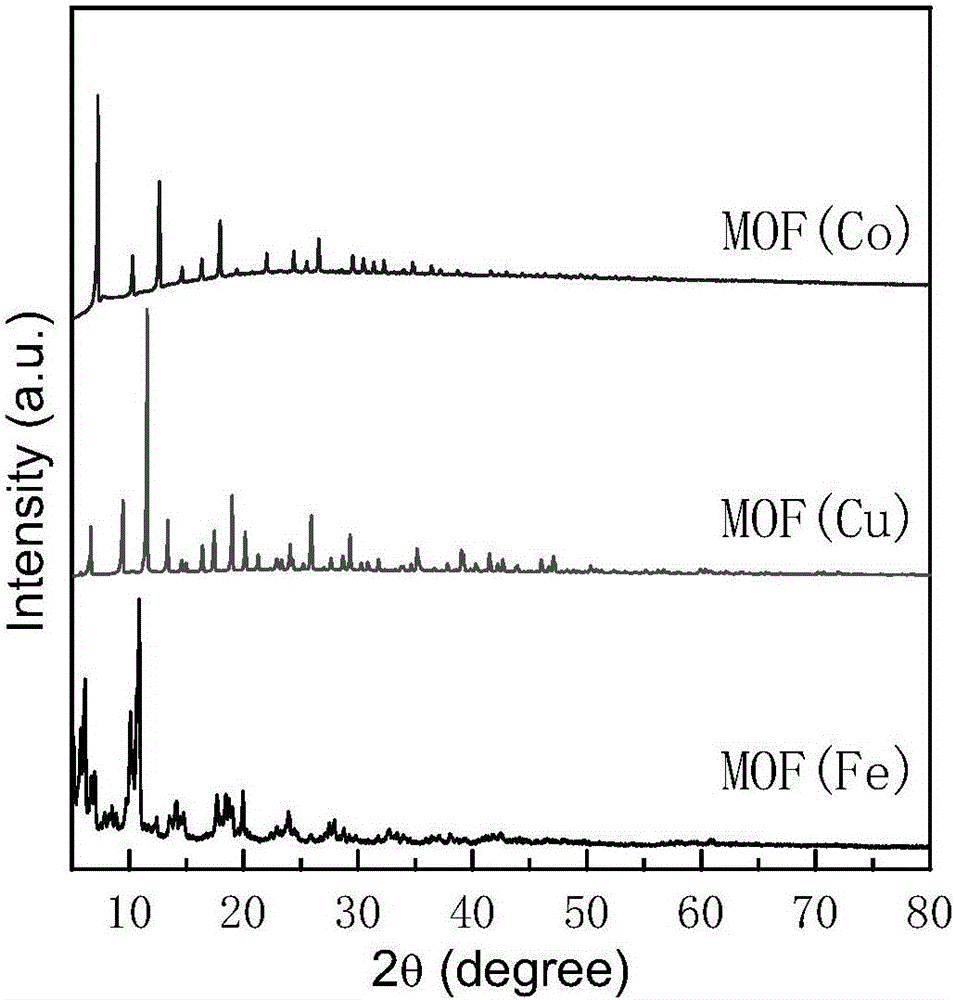

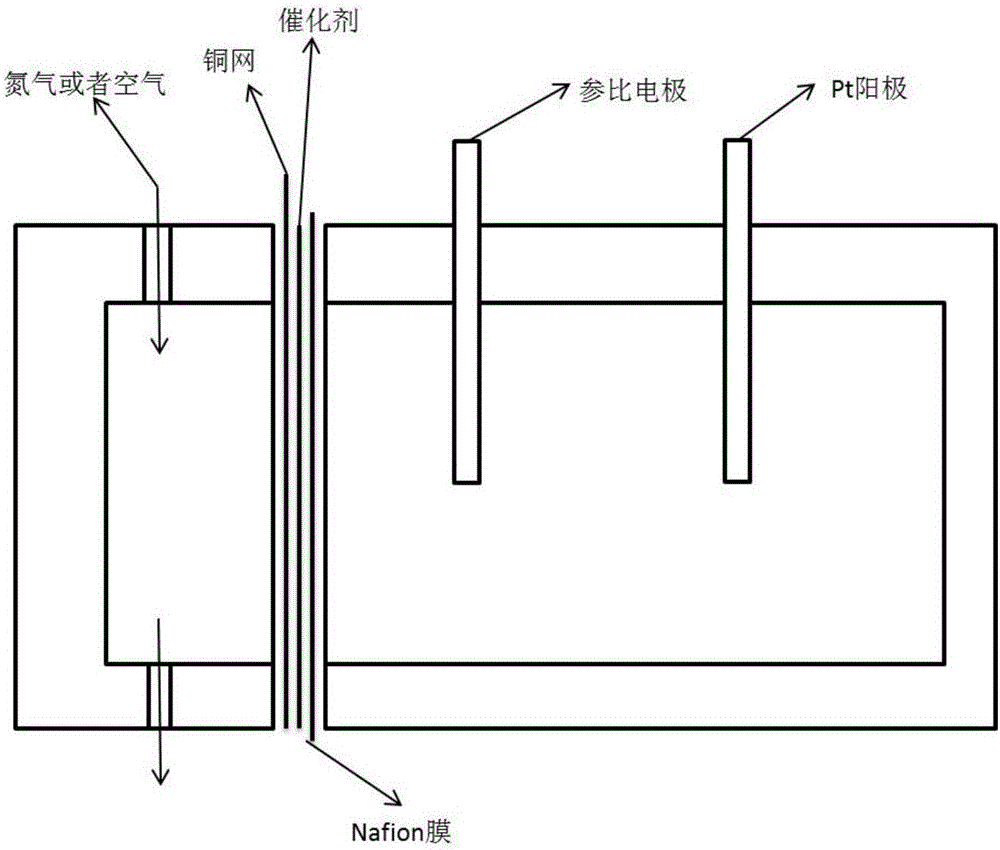

[0024] MOF(Cu) is selected as the metal-organic framework material, and the synthesis step is Cu(NO 3 ) 2 ·3H 2 O, 1,3,5-BTC, according to a certain molar ratio (Cu 2+ :1,3,5-BTC:H 2 O=3:6:2) were dissolved in 180ml of water and 180ml of absolute ethanol respectively, and after stirring for 1 hour until uniform, the Cu(NO 3 ) 2 ·3H 2 O solution was dropped into 1,3,5-BTC solution and stirred for 2 hours. The mixed solution was then transferred to a polytetrafluoroethylene-lined jelly, then loaded into a stainless steel hydrothermal jelly, and placed in an oven, kept at 120°C for 24 hours and then cooled to room temperature. The product was filtered and washed, and the final product was dried in a vacuum oven at 60°C to obtain a MOF (Cu) sample, whose XRD pattern is as follows figure 1 shown. With the mass ratio of MOF(Cu):graphite:nafion=80:15:5, where the concentration of nafion is 80wt%, mix it with absolute ethanol to make a slurry, and evenly coat it on 4cm 2 On h...

Embodiment 2

[0026] MOF(Cu) is selected as the metal-organic framework material, and the synthesis step is Cu(NO 3 ) 2 ·3H 2 O, 1,3,5-BTC, according to a certain molar ratio (Cu 2+ :1,3,5-BTC:H 2 O=3:6:2) were dissolved in 180ml of water and 180ml of absolute ethanol respectively, and after stirring for 1 hour until uniform, the Cu(NO 3 ) 2 ·3H 2 O solution was dropped into 1,3,5-BTC solution and stirred for 2 hours. The mixed solution was then transferred to a polytetrafluoroethylene-lined jelly, then loaded into a stainless steel hydrothermal jelly, and placed in an oven, kept at 120°C for 24 hours and then cooled to room temperature. The product was filtered and washed, and the final product was dried in a vacuum oven at 60°C to obtain a MOF (Cu) sample, whose XRD pattern is as follows figure 1 shown. With the mass ratio of MOF (Cu): acetylene black: polytetrafluoroethylene: = 85:13.5:1.5, wherein the concentration of polytetrafluoroethylene is 5wt%, mixed evenly with absolute e...

Embodiment 3

[0028] The metal-organic framework material is MOF(Fe), and the synthesis step is Fe(NO 3 ) 3 9H 2 O, 1,3,5-BTC, 5mol / LHF and water according to a certain molar ratio (Fe 3+ :1,3,5-BTC:HF:H 2 (0=1.0:0.66:2.0:280) were mixed and stirred for 3-4 hours. The mixture was then transferred to a polytetrafluoroethylene-lined box, loaded into a stainless steel hydrothermal box, placed in an oven, and reacted at 150 °C for 84 hours before cooling to room temperature. The product was filtered and washed, and the final product was dried in a vacuum oven at 60°C to obtain a MOF(Fe) sample, whose XRD pattern is as follows figure 1 shown. With the mass ratio of MOF(Fe):carbon black:nafion:=80:1:5, wherein the concentration of nafion is 90wt%, mixed with absolute ethanol to make a slurry, uniformly coated on 4cm 2 On hydrophobic carbon paper, dry at 100°C for 8h, used for electrochemical synthesis of ammonia experiment, the reaction temperature is 80°C, the voltage is -1.2V, the synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com