Foaming basalt material used for high speed train and manufacturing method

A technology of high-speed trains and production methods, which is applied in the field of building decoration materials, can solve problems such as surface scratches, failure to meet market demand, and lack of fire resistance, and achieve the effects of long service life, good thermal insulation performance, and convenient combination and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

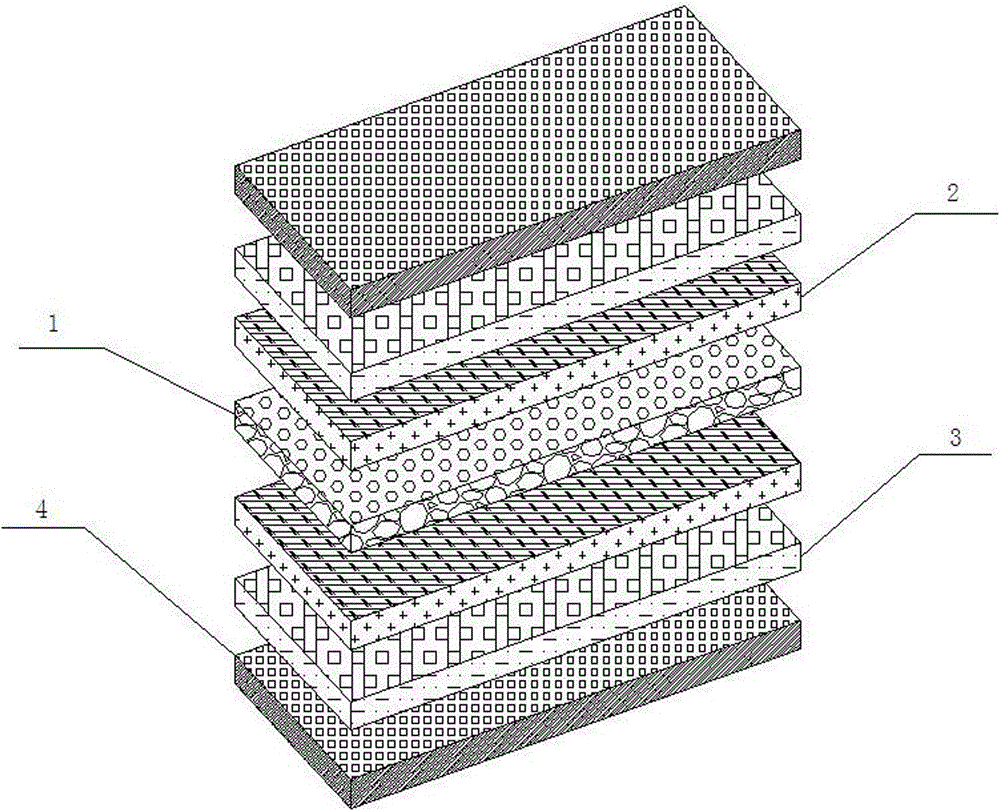

[0021] A foamed basalt material for high-speed trains, characterized in that: it includes a foamed basalt plate 1, a flame-retardant PEF foam 2, a foamed aluminum plate 3, and a veneer 4; the foamed basalt plate 1 is surrounded by flame-retardant PEF Foam 2, the outer surface of the flame-retardant PEF foam 2 is connected to the foamed aluminum plate 3, and the outer surface of the foamed aluminum plate 3 is connected to the decorative panel 4; the foamed basalt plate 1 and the flame-retardant PEF foam 2 are connected by gluing, so The foamed aluminum plates 3 are connected by a broken bridge structure, and the veneer 4 and the foamed aluminum plates 3 are connected by gluing.

[0022] A preferred technical solution is: the foamed basalt board 1 and the flame-retardant PEF foam 2 are connected by a polycarbonate adhesive.

[0023] A preferred technical solution is: the foamed aluminum plate 3 and the veneer 4 are connected by environmentally friendly glue.

[0024] A preferre...

Embodiment 2

[0032] In the present invention, in the manufacturing method of the foamed basalt material used for high-speed trains, when step 1 is carried out according to the following scheme: put the mixed dry powder of basalt into the kiln, heat up at a rate of 10-25° C. / min, and set the temperature at 600- After melting and sintering at 900°C, keep it warm for 10-15 minutes, then cool it down to 320-400°C at a rate of 20-30°C / min, then keep it warm for 15-45 minutes, and then cool it to room temperature with the furnace to form it, and then make it into a basalt environmental protection wallboard foaming material .

[0033] The foamed basalt material for high-speed trains of the present invention has a large number of fine closed-cell bubble structures, the pore size varies from nanometer to micrometer, and the distribution of cells is uniform. The main technical indicators are shown in Table 1.

[0034] Table 1: the main technical index of the expanded basalt material that high-speed ...

Embodiment 3

[0037] In the present invention, in the production method of the foamed basalt material for high-speed trains, when step 1 is carried out according to the following scheme: put the mixed dry powder of basalt into the kiln, heat up at a rate of 10°C / min, and melt and sinter at 600°C After it is finished, keep it warm for 10 minutes, then cool it down to 320 ℃ at a rate of 20 ℃ / min, then keep it warm for 15 minutes, and then cool it to room temperature with the furnace to form it, and then it is made into a basalt environmental protection wallboard foaming material.

[0038] The foamed basalt material for high-speed trains of the present invention has a large number of fine closed-cell bubble structures, the pore size varies from nanometer to micrometer, and the distribution of pores is uniform. The main technical indicators are shown in Table 2.

[0039] Table 2: the main technical index of the expanded basalt material that high-speed train of the present invention is used:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap