Composite asphalt-based active carbon preparation method and supercapacitor

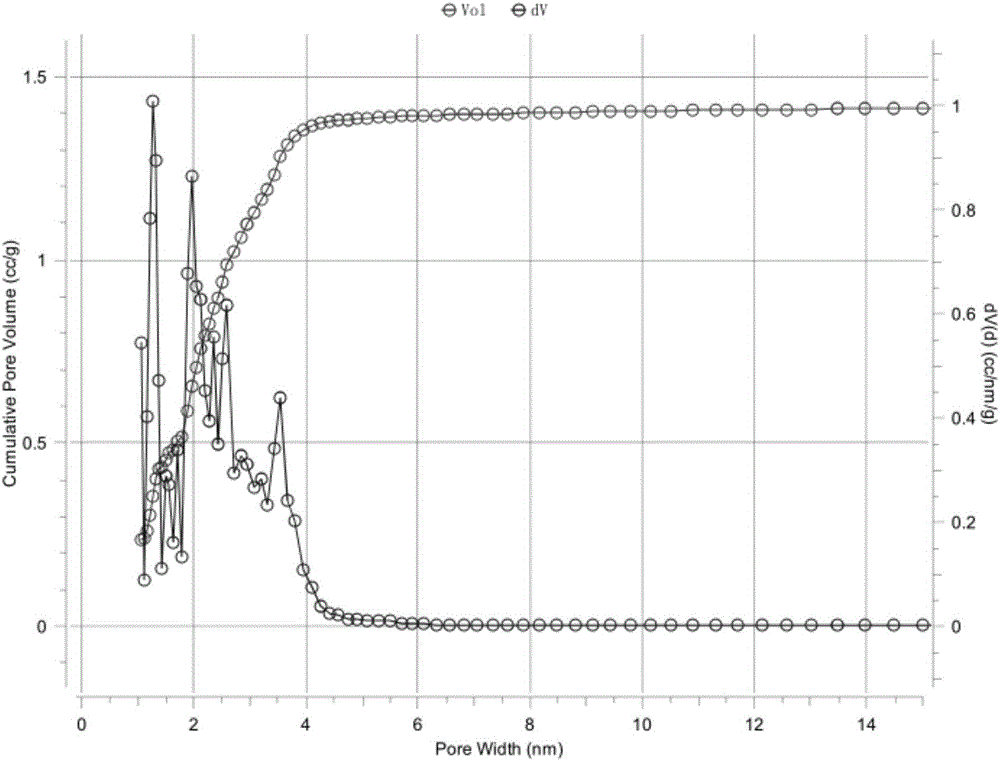

A pitch-based, composite technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low mesoporous content, low specific capacity, and high internal resistance, and achieve the effect of reducing internal resistance and increasing mesoporosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a kind of preparation method of composite pitch-based activated carbon, comprising the following steps:

[0040] A) after the matrix pitch after melting is mixed with graphene oxide, a mixture is obtained;

[0041] B) Under the condition of inert gas and / or nitrogen, after coking and reducing the mixture obtained in the above steps, mixed green coke is obtained;

[0042] C) pulverizing the mixed raw coke obtained in the above steps, mixing it with alkali again, and performing preactivation and activation under the conditions of inert gas and / or nitrogen to obtain a semi-finished product;

[0043] D) After washing and drying the semi-finished product obtained in the above steps, under the condition of protective gas, after heat treatment, the composite pitch-based activated carbon is obtained.

[0044] In the present invention, firstly, the melted base pitch and graphene oxide are mixed to obtain the mixture.

[0045] The present invention has no...

Embodiment 1

[0066] Take 500g of coal tar pitch, heat it to melt, and keep the temperature at 150°C; weigh 5g of graphene oxide powder and add it to coal tar pitch, stir for 20min, then use a shearing machine to stir for 90min at a shear rate of 150rmp; cool down to 120°C and place 60min, then cut again for 90min to obtain fully dispersed coal tar pitch with graphene oxide;

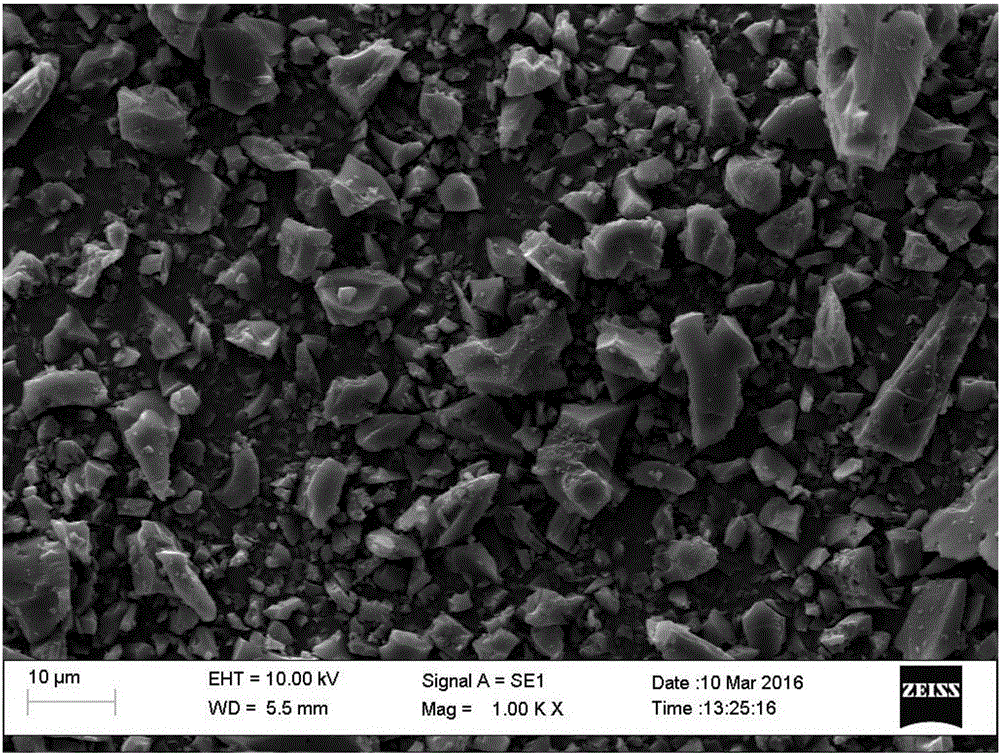

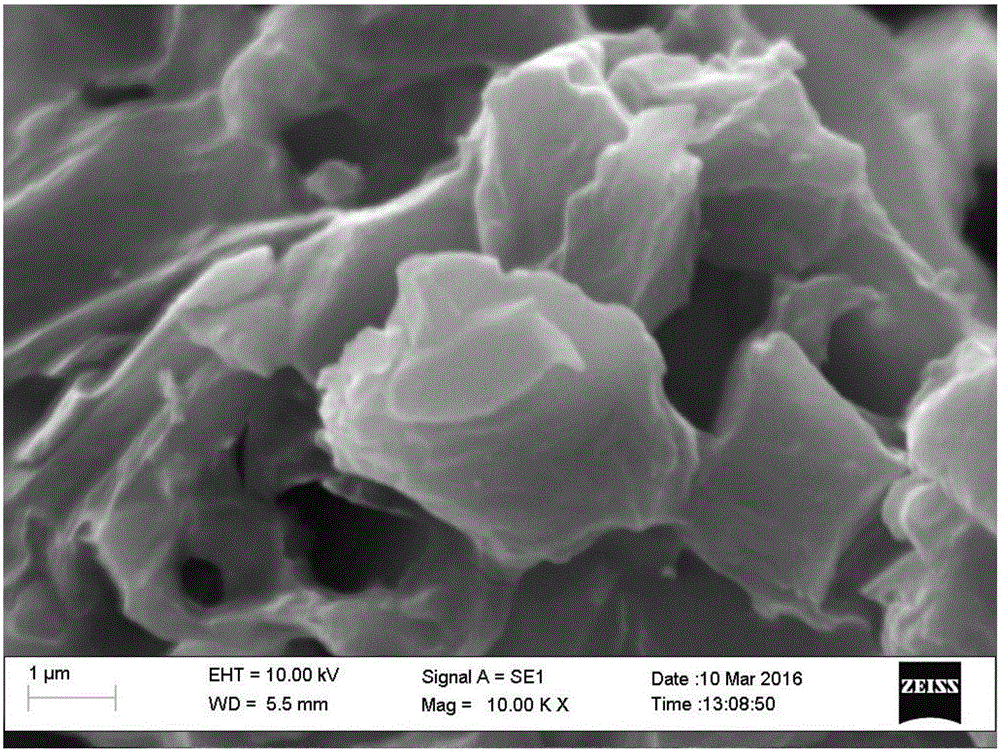

[0067] Under the protection of nitrogen, heat the pitch to 450°C in a coking furnace for 8 hours, cool it naturally, and then crush it into a powder of 50-100 μm in a pulverizer; add 1500g of powdered KOH and mix evenly. Put this mixture into a metal nickel crucible, raise the temperature to 450°C at a rate of 10-20°C / min under nitrogen atmosphere and keep it for 3h; . The product was dissolved in water, washed repeatedly until neutral, then added with 6M hydrochloric acid to reflux for 2 hours, filtered, washed with deionized water until neutral, and dried in vacuum. Put the obtained solid powder into a rotary furn...

Embodiment 2

[0073] Take 200g of coal tar pitch, heat it to melt, and keep the temperature at 180°C; weigh 1g of graphene oxide powder and add it to coal tar pitch, stir for 20min, then use a shear to stir for 90min at a shear rate of 150rmp; cool down to 120°C and place 60min, then cut again for 90min to obtain fully dispersed coal tar pitch with graphene oxide;

[0074] Under the protection of nitrogen, heat the asphalt in the coking furnace to 500°C for 6 hours, cool naturally, and then pulverize it into a powder of 50-100 μm in a pulverizer; add 500g of powdered KOH and mix evenly. Put this mixture into a metal nickel crucible, raise the temperature to 450°C at a rate of 10-20°C / min under nitrogen atmosphere and keep it for 3h; room temperature. The product was dissolved in water, washed repeatedly until neutral, then added with 6M hydrochloric acid to reflux for 2 hours, filtered, washed with deionized water until neutral, and dried in vacuum. Put the obtained solid powder into a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com