Method for preparing nitrogen-containing porous carbon by using recycled waste carbon and production and application thereof

A technology of porous carbon and waste activated carbon, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of unrecoverable catalysts, large corrosion of reaction equipment, and high production costs, and achieves a simple preparation method. Ease of operation, lower recycling costs, and the effect of lowering recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The waste charcoal produced in the decolorization process in the biotin production process is used as raw material.

[0039] Weigh 2g of spent activated carbon, 8g of sodium bicarbonate and 8g of ammonium oxalate, transfer them to a 30ml crucible after mechanical mixing, and then calcine them in a nitrogen furnace. The steps of calcining are: heating up to 900°C at 15°C / min, calcining at 900°C for 1 hour; then cooling down to room temperature naturally. The calcined product was ground, mixed with deionized water, filtered after standing for 24 hours, the precipitate was washed until neutral, and dried to obtain the nitrogen-containing porous carbon material.

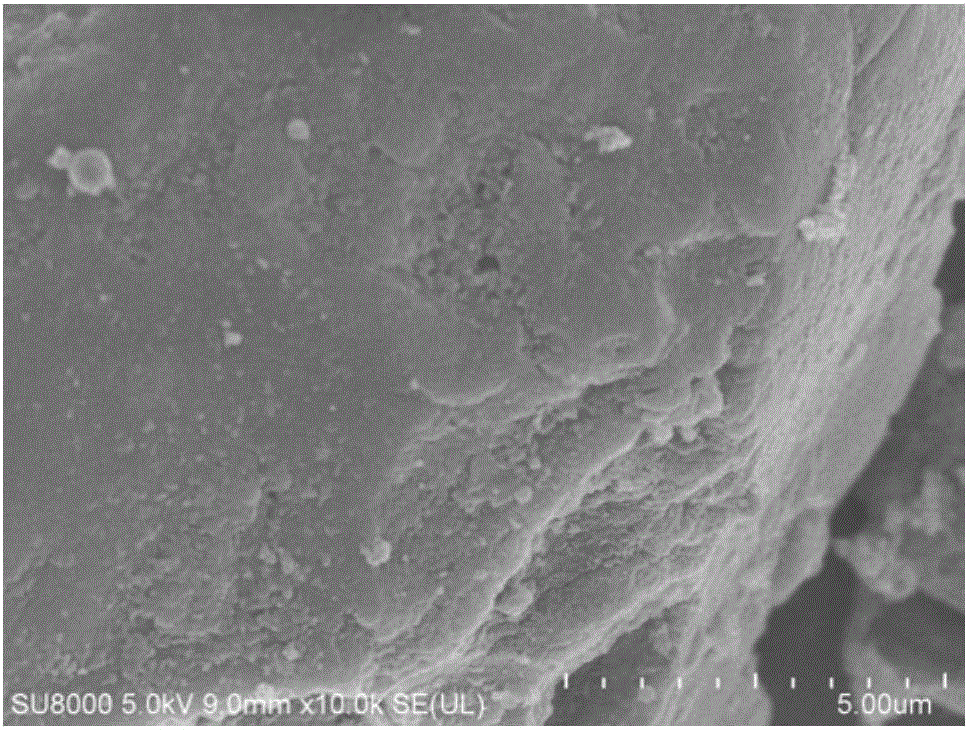

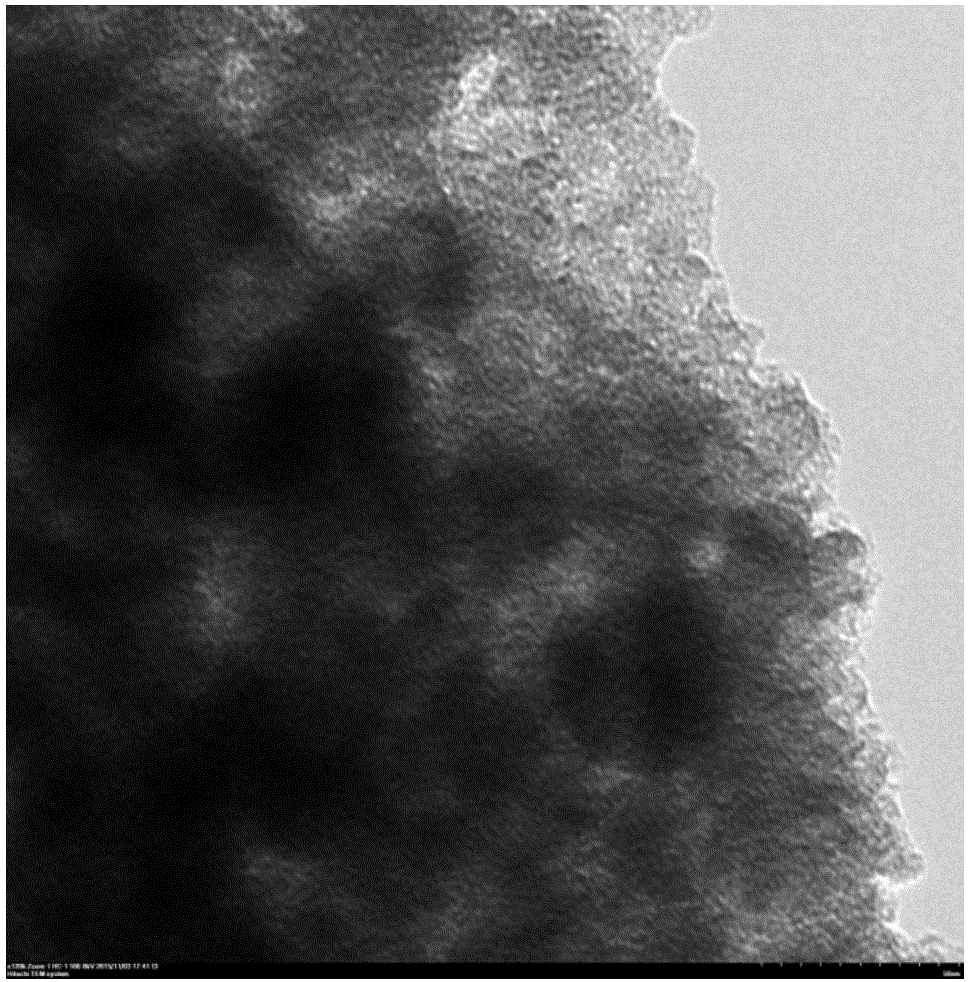

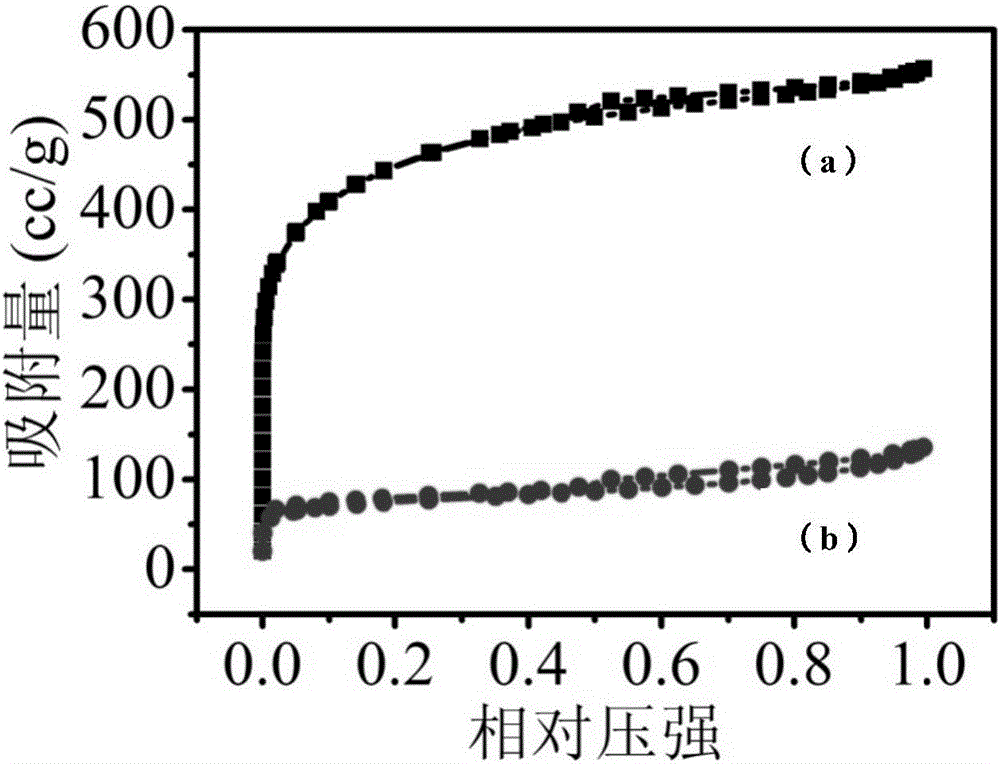

[0040] The SEM and TEM images of the nitrogen-containing porous carbon material prepared in this example are as follows figure 1 , 2 Shown:

[0041] Observed figure 1 It can be seen that the surface of the activated carbon material contains some pores, and its microporous structure can be determi...

Embodiment 2

[0060] Embodiment 2: Taking the waste activated carbon after the decolorization of the sugar industry as raw material

[0061] Weigh 2g of spent activated carbon and mechanically mix with 8g of sodium bicarbonate and 8g of potassium oxalate, then transfer to a 30ml crucible. Calcination is then carried out in a nitrogen furnace. The calcining steps are: heating up to 900°C at 15°C / min, calcining at 900°C for 1 hour; then cooling down to room temperature naturally. Grind the calcined mixture, then wash with 300ml deionized water, filter after 24h, wash until neutral, and dry to obtain a nitrogen-containing porous carbon material. Its scanning electron microscope (SEM) image is as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com