High temperature resistant radar and infrared compatible camouflage material and preparation method thereof

A stealth material and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant radar and infrared-compatible stealth materials and their preparation, can solve problems such as lack of infrared stealth performance, poor broadband and low-frequency absorbing performance, and no contribution to absorbing performance, etc., to achieve It is easy to realize the effect of engineering application, good broadband absorbing function and good low frequency absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

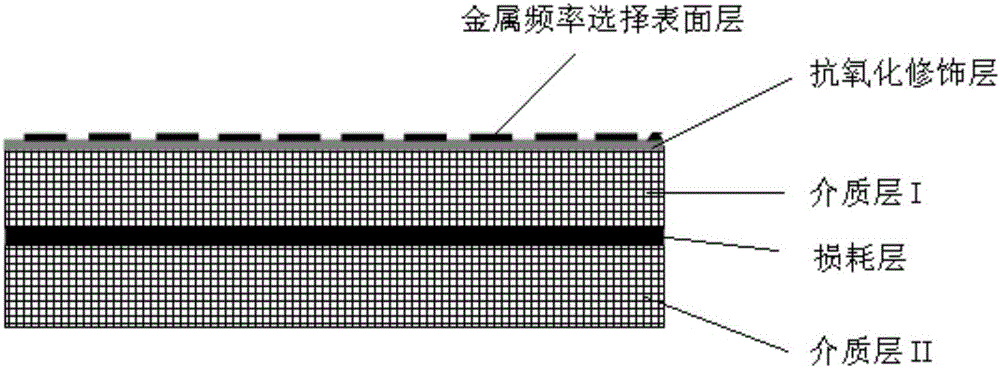

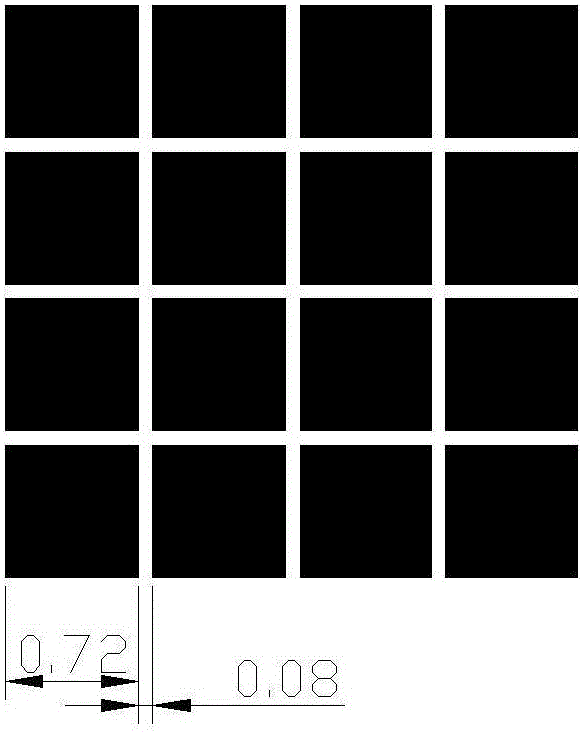

[0045] A high temperature resistant radar and infrared compatible stealth material of the present invention, the structure diagram is as follows figure 1 As shown, it is mainly composed of a silicon carbide composite material layer, an oxidation-resistant modification layer, and a rectangular metal frequency selective surface layer; among them, the silicon carbide composite material layer is a superimposed structure composed of dielectric layer I, loss layer, and dielectric layer II. The resistivity of continuous silicon carbide fibers in dielectric layer I and dielectric layer II are both 7×10 6 Ω·cm~8×10 6 Ω·cm, the thickness of dielectric layer I and dielectric layer II are 2.05mm and 2.5mm respectively; the resistivity of the continuous silicon carbide fiber in the loss layer is 5.2Ω·cm, and the thickness of the loss layer is 0.4mm; the anti-oxidation modification layer refers to Cordierite glass coating, the thickness is 0.05mm; the metal coating refers to the platinum coati...

Embodiment 2

[0054] A high temperature resistant radar and infrared compatible stealth material of the present invention, the structure diagram is as follows figure 1 As shown, it is mainly composed of a silicon carbide composite material layer, an oxidation-resistant modification layer, and a rectangular metal frequency selective surface layer; among them, the silicon carbide composite material layer is a superimposed structure composed of dielectric layer I, loss layer, and dielectric layer II. The resistivity of continuous silicon carbide fibers in dielectric layer I and dielectric layer II are both 7×10 6 Ω·cm~8×10 6 Ω·cm, the thickness of dielectric layer I and dielectric layer II are 2.3mm and 2.5mm respectively; the resistivity of the continuous silicon carbide fiber in the loss layer is 4.8Ω·cm, and the thickness of the loss layer is 0.4mm; the anti-oxidation modification layer is Refers to the cordierite glass coating with a thickness of 0.1mm; the metal coating refers to the platinu...

Embodiment 3

[0063] A high temperature resistant radar and infrared compatible stealth material of the present invention, the structure diagram is as follows figure 1 As shown, it is mainly composed of a silicon carbide composite material layer, an anti-oxidation modification layer, and a rectangular metal frequency selective surface layer; among them, the silicon carbide composite material layer is a superimposed structure composed of dielectric layer I, loss layer, and dielectric layer II , The resistivity of continuous silicon carbide fibers in dielectric layer I and dielectric layer II are both 7×10 6 Ω·cm~8×10 6 Ω·cm, the thickness of dielectric layer I and dielectric layer II are 4.97mm and 4.92mm, respectively; the resistivity of the continuous silicon carbide fiber in the loss layer is 6.5Ω·cm, and the thickness of the loss layer is 0.41mm; among them, the oxidation-resistant modified layer It refers to the cordierite glass coating, the thickness of the anti-oxidation modification lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com