Method for synthesizing Cr3<+> absorption resin by taking carboxymethyl potato starch as raw material

A potato starch, carboxymethyl technology, applied in adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of polluted cultivated land, large area, large investment in ion exchange method, etc. The effect of strong adsorption capacity, excellent performance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

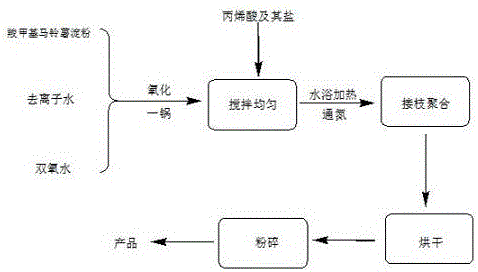

Method used

Image

Examples

Embodiment 1

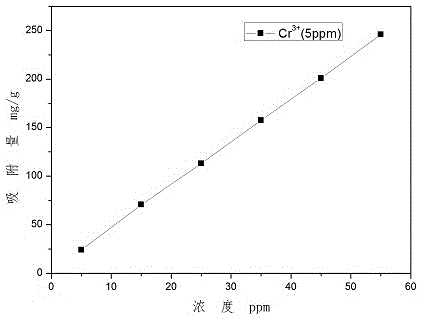

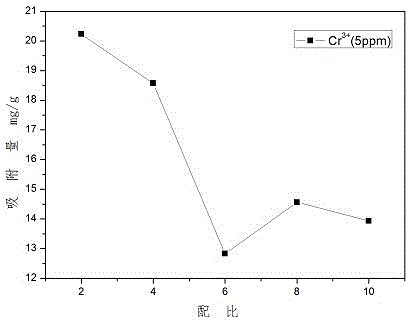

[0022] Example 1: Weigh 5g of carboxymethyl potato starch and 50ml of deionized water and mix evenly, add 6ml of 30% hydrogen peroxide and oxidize at 50°C for 1h, measure 20g (19.1ml) of acrylic acid, weigh 5.6g of sodium hydroxide and dissolve in In 30ml of deionized water, use the NaOH solution prepared above to neutralize acrylic acid under cooling in an ice-water bath, fully mix the neutralized acrylic acid and its sodium salt solution with the oxidized carboxymethyl potato starch solution, and add 4ml of 2.5mg / ml N, N'-methylenebisacrylamide solution, in N 2 Under protection, heat slowly to increase the temperature of the system gradually. After the polymerization reaction starts, stop stirring, continue to raise the temperature slowly, and keep warm at 80°C for 2 hours. The product is dried and crushed to obtain the product. The product prepared in this example is in Cr in a solution with a concentration of 25ppm 3+ The adsorption capacity is 113.1mg / g.

Embodiment 2

[0023] Example 2: Weigh 5g of carboxymethyl potato starch and mix with 50ml of deionized water evenly, add 6ml of hydrogen peroxide and oxidize at 50°C for 1h, measure 20g (19.1ml) of acrylic acid, weigh 5.6g of sodium hydroxide and dissolve in 50ml of deionized water Ionized water, use the sodium hydroxide solution prepared above to neutralize acrylic acid under cooling in an ice-water bath, fully mix the neutralized acrylic acid and its salt solution with the oxidized carboxymethyl potato starch solution, and add 6ml to a concentration of 2.5 mg / ml N, N'-methylenebisacrylamide solution, in N 2 Under protection, heat slowly to increase the temperature of the system gradually. After the polymerization reaction starts, stop stirring, continue to raise the temperature slowly, keep it at 80°C for 2 hours, dry and pulverize to obtain the product. The product that is made by the present embodiment is 35ppmCr at concentration 3+ Cr in the solution 3+ The adsorption capacity is 157...

Embodiment 3

[0024] Example 3: Weigh 5g of carboxymethyl potato starch and 50ml of deionized water and mix evenly, add 6ml of hydrogen peroxide and oxidize at 50°C for 1h, measure 30g (28.57ml) of acrylic acid, weigh 8.4g of sodium hydroxide and dissolve in 50ml of deionized water Ionized water, use the sodium hydroxide solution prepared above to neutralize acrylic acid under cooling in an ice-water bath, fully mix the neutralized acrylic acid and its salt solution with the oxidized carboxymethyl potato starch solution, and add 4ml to a concentration of 2.5 mg / ml N, N'-methylenebisacrylamide solution, in N 2 Under protection, heat slowly to increase the temperature of the system gradually. After the polymerization reaction starts, stop stirring, continue to raise the temperature slowly, keep it at 80°C for 2 hours, dry and pulverize to obtain the product. The product that is made by present embodiment is 5ppmCr at concentration 3+ Cr in the solution 3+ The adsorption capacity is 23.95mg / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com