Genetically engineered bacterium capable of generating polyhydroxybutyrate hydroxyvalerate and application method of genetically engineered bacterium

A technology of polyhydroxybutyrate hydroxyvalerate and genetically engineered bacteria, which is applied in the fields of genetic engineering and fermentation engineering, can solve the problems of low mole fraction and increased fermentation production costs, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The construction of embodiment 1 recombinant bacteria WM002

[0028] (1) Taking Eutropha rosenbergii genome NC_008313.1 as a template, primers phaCAB-F / phaCAB-R were used to amplify the phaCAB gene cluster, and the sequence of the primer phaCAB-F / phaCAB-R for amplifying the phaCAB gene cluster was

[0029] phaCAB-F: 5'-CTGGAATTCAGAAGGAGAATCAAATCATGGCGACCGG-3'

[0030] phaCAB-R: 5'-CCGCTCGAGAGGTCAGCCCATATGCAGG-3'

[0031] (2) Digest the PCR product with restriction endonucleases EcoRI and XhoI, the carrier pDXW-8 (the construction method of the carrier pDXW-8 refers to the application number 200910233618.1, and the name of the invention is a kind of Escherichia coli-coryneform bacteria shuttle type inducible expression carrier PDXW -8 and the patent application for its construction method) were digested with EcoRI and XhoI, and after purification of the digested products, they were treated overnight at 22°C with T4 ligase, transformed into Escherichia coli DH5α, and the...

Embodiment 2

[0033] Embodiment 2 uses Corynebacterium glutamicum genetically engineered bacteria WM002 shake flask fermentation to produce PHBV

[0034] (1) Shake flask fermentation of recombinant genetically engineered bacteria

[0035] Medium (g / 100mL): corn steep liquor 1.5, ammonium sulfate 3.5, magnesium sulfate 0.05, potassium dihydrogen phosphate 0.1, glucose 13, calcium carbonate 2, pH 7.2.;

[0036] Culture method: 31°C, 230rpm, culture for 96h.

[0037] Induction conditions: IPTG was added at a final concentration of 0.5 mM at 6 hours.

[0038] (2) Esterification of intracellular polyhydroxyalkanoate of genetically engineered bacteria WM002 and WM001 / pDXW-8 in Example 1: after the thalline in the obtained fermentation broth was centrifuged, wash two times with the phosphate buffer saline of pH 7.0 The second time, freeze-dry overnight in a vacuum freeze dryer, weigh about 20 mg of dried bacteria (mass is recorded as Wt), add it to the esterification tube, and then add 2 mL of c...

Embodiment 3

[0045] Example 3 Intracellular accumulation of Corynebacterium glutamicum genetically engineered bacteria ATCC13869 / pDXW-8-phaCAB shake flask fermentation is PHB instead of PHBV

[0046] (1) Shake flask fermentation of recombinant genetically engineered bacteria

[0047] The construction method of recombinant bacteria ATCC3869 / pDXW-8-phaCAB and ATCC3869 / pDXW-8 refers to (1) in Example 2;

[0048] (2) with (2) in embodiment 2;

[0049] (3) with (3) in embodiment 2;

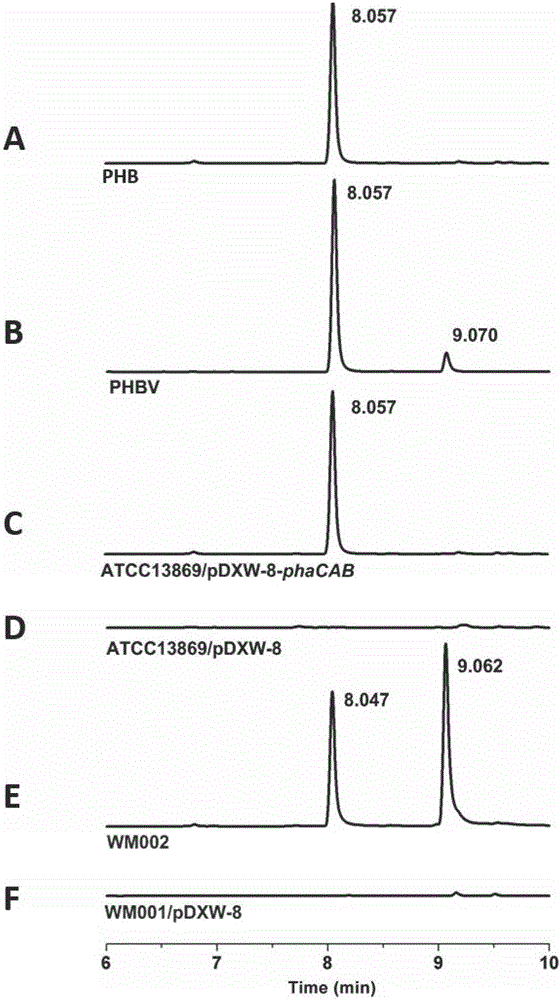

[0050] (4) with (4) in embodiment 2; Draw the esterification product of genetic engineering bacterium ATCC3869 / pDXW-8-phaCAB to have only 1 characteristic peak (such as figure 1 Shown in C), can correspond to standard sample PHB characteristic peak (such as figure 1 Shown in A), there is no PHV characteristic peak in the PHBV standard sample (such as figure 1 Shown in B), the esterification product of ATCC3869 / pDXW-8 has no characteristic peak (as figure 1 Shown in D) shows that its intracellular synthetic pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com