Ti-Al-Mo-N multi-component hard gradient film as well as preparation method and application thereof

A multi-component, gradient film technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., to achieve simple production methods, improve corrosion resistance, coating wear resistance, and high ionization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Determination of deposition technology and preparation of alloy targets:

[0055] The Bulat-6 multi-arc ion coating machine is used to deposit the coating. The coating machine is composed of a vacuum system, a coating system, and an electrical control system without an additional magnetic filter system. There are three arc sources in the coating chamber, and the arc sources on the left and right sides are used to initiate arc deposition.

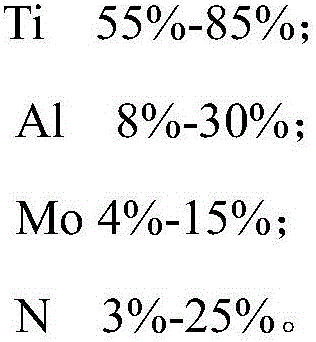

[0056] The design, selection and preparation of the target material: when TIN coating is applied, the commercially pure titanium target purchased is selected, the purity is 99.9%, and the shape of the titanium target is processed into a circular target with a diameter of φ60mm and a thickness of 42mm according to the requirements of the equipment. When the Ti-Al-Mo-N coating is applied, the target material is a self-made alloy target. The composition of the alloy target is designed as follows: the mass percentage of Ti is 75%, th...

Embodiment 2

[0068] (1) Determination of deposition technology and preparation of alloy targets:

[0069] The Bulat-6 multi-arc ion coating machine is used to deposit the coating. The coating machine is composed of a vacuum system, a coating system, and an electrical control system without an additional magnetic filter system. There are three arc sources in the coating chamber, and the arc sources on the left and right sides are used to initiate arc deposition.

[0070] The design, selection and preparation of the target material: when TIN coating is applied, the commercially pure titanium target purchased is selected, the purity is 99.9%, and the shape of the titanium target is processed into a circular target with a diameter of φ60mm and a thickness of 42mm according to the requirements of the equipment. When the Ti-Al-Mo-N coating is applied, the target material is a self-made alloy target. The composition of the alloy target is designed as follows: the mass percentage of Ti is 75%, th...

Embodiment 3

[0082] (1) Determination of deposition technology and preparation of alloy targets:

[0083] The Bulat-6 multi-arc ion coating machine is used to deposit the coating. The coating machine is composed of a vacuum system, a coating system, and an electrical control system without an additional magnetic filter system. There are three arc sources in the coating chamber, and the arc sources on the left and right sides are used to initiate arc deposition.

[0084] The design, selection and preparation of the target material: when TIN coating is applied, the commercially pure titanium target purchased is selected, the purity is 99.9%, and the shape of the titanium target is processed into a circular target with a diameter of φ60mm and a thickness of 42mm according to the requirements of the equipment. When the Ti-Al-Mo-N coating is applied, the target material is a self-made alloy target. The composition of the alloy target is designed as follows: the mass percentage of Ti is 70%, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com