Silver paste of high-performance lead-free crystalline silicon solar battery back electrode and preparation method thereof

A technology of solar cells and lead-free crystalline silicon, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., which can solve the problem of large contact resistance and series resistance, insufficient density of the silver layer of the silver electrode, and Insufficient adhesion of silver electrodes and other problems, to achieve the effect of enhancing compactness, improving solderability and solder resistance, and improving fusion contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

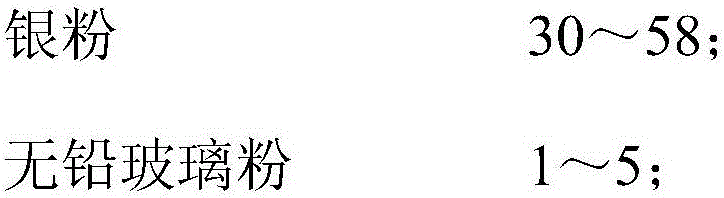

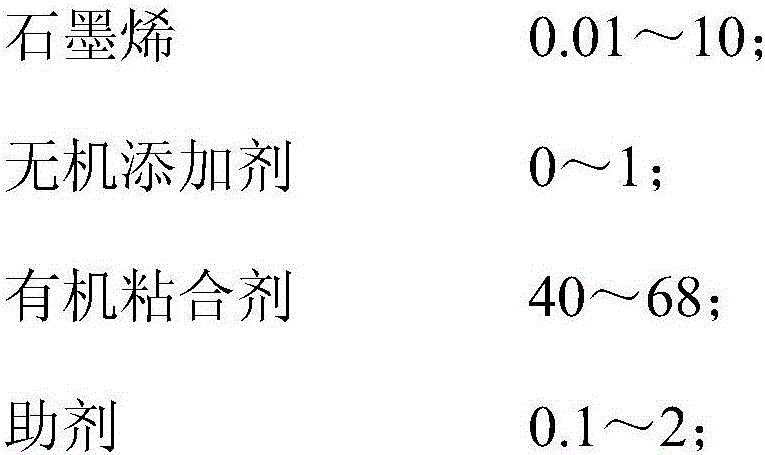

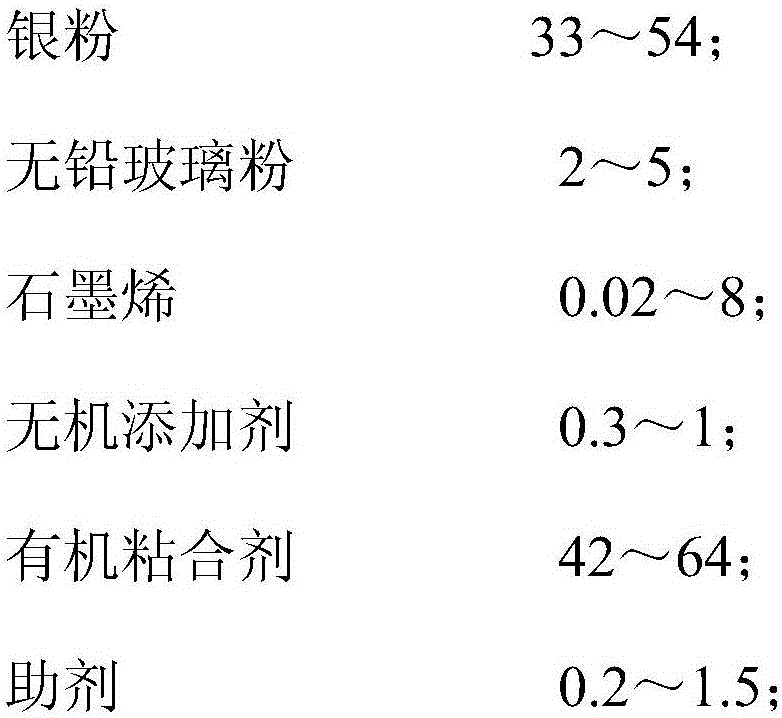

Method used

Image

Examples

Embodiment 1

[0043] (1) prepare graphene slurry:

[0044] Weigh 0.01g graphene (thickness is 3nm, sheet size is 5μm, specific surface area is 300㎡ / g), organic binder 10g, auxiliary agent is dispersant and leveling agent, wherein BYK-110 is used as dispersant , and weigh 0.1g of the dispersant, use BYK-333 as the leveling agent, and weigh 0.1g of the leveling agent, stir and mix in the container, grind and disperse on the three-roll mill to control the slurry The fineness is less than 15μm.

[0045] (2) Prepare back electrode silver paste:

[0046] Weigh 10g of irregular silver powder, 20g of high specific surface area silver powder, 58g of organic binder, 1.5g of lead-free glass powder, 0.09g of boron powder, and 0.2g of silicon powder. Continue to stir and mix the graphene slurry evenly, and then grind and disperse it on a three-roll mill to control the slurry fineness to less than 15 μm and viscosity to 30 Pa·s (25°C, Brookfield HBIIPro+).

[0047] The above silver paste is on productio...

Embodiment 2

[0051] (1) prepare graphene slurry:

[0052] Weigh 1g of graphene (thickness is 2nm, sheet size is 3μm, specific surface area is 400㎡ / g), organic binder 10g, auxiliary agent is dispersant and leveling agent, wherein BYK-110 is used as dispersant, And take the dispersant 0.1g, adopt BYK-333 as the leveling agent, and take the leveling agent 0.1g, stir and mix in the container, grind and disperse on the three-roll mill, control the fineness of the slurry The degree is less than 15 μm.

[0053] (2) Prepare back electrode silver paste:

[0054] Weigh 42g of silver powder with high specific surface area, 41.5g of organic binder, 5g of lead-free glass powder, 0.1g of boron powder, and 0.2g of silicon powder, stir and mix in the container, then add graphene slurry, continue to stir and mix evenly , and then grind and disperse on a three-roll mill to control the slurry fineness to less than 15 μm and viscosity to 70 Pa·s (25°C, Brookfield HB Ⅱ Pro+).

[0055] Above-mentioned embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com