A method for preparing fept pseudo-spin valve material

A pseudo-spin valve and substrate technology, which is applied in spin exchange-coupled multilayer films, magnetic film-to-substrate applications, inductor/transformer/magnet manufacturing, etc. problem, to achieve the effect of simple preparation, convenient control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

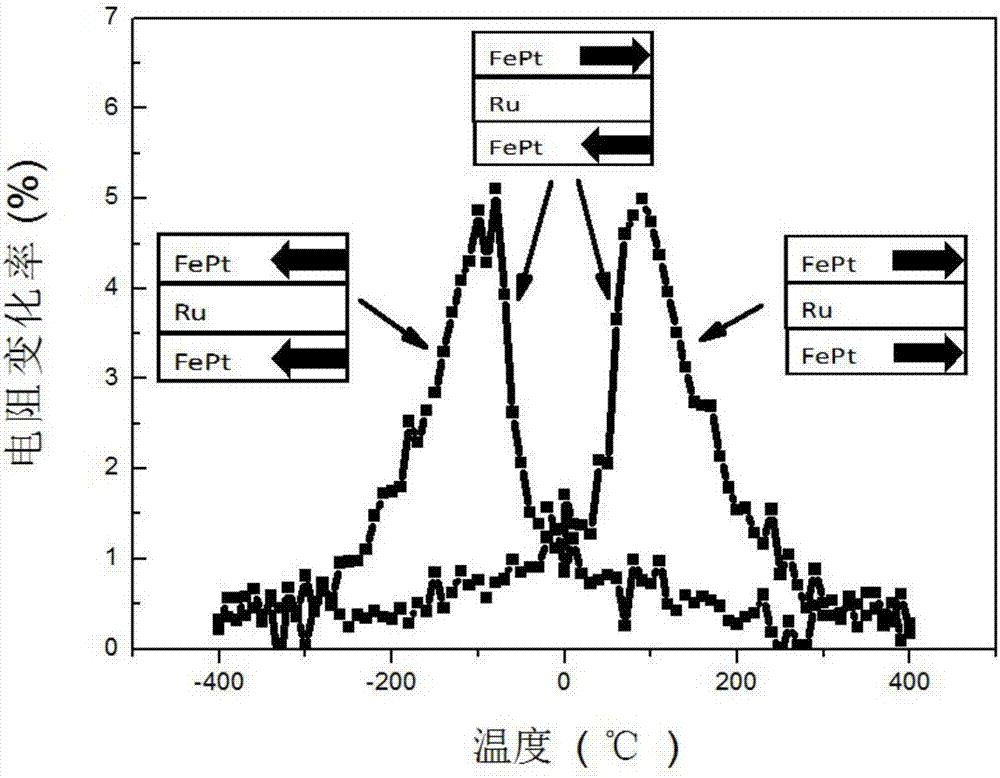

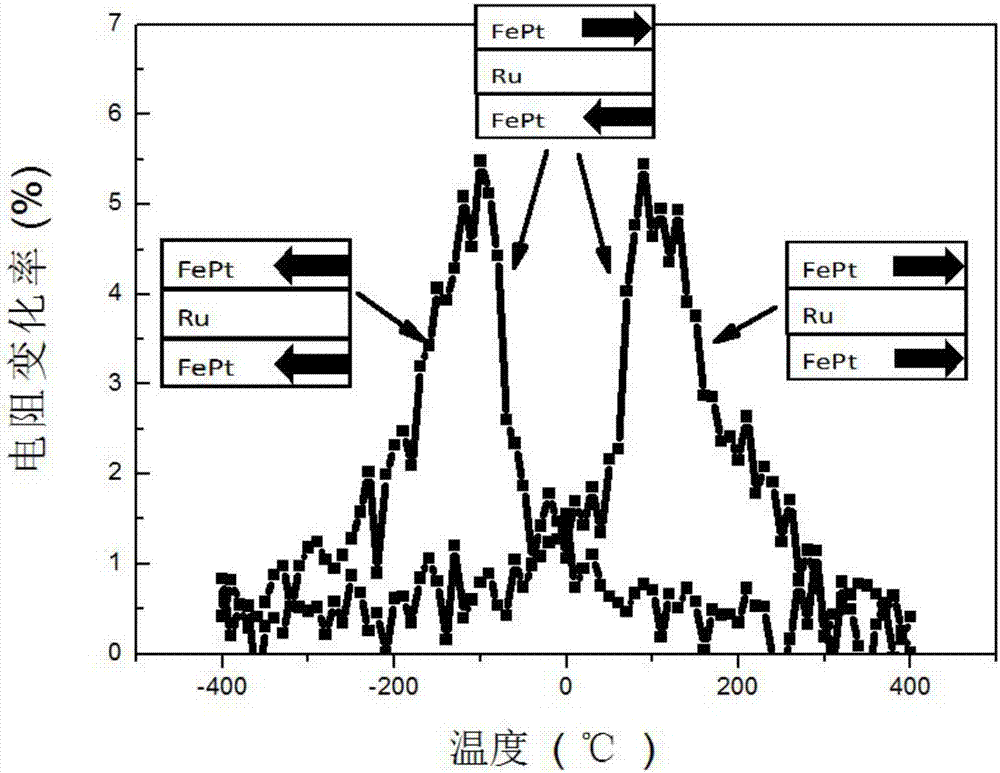

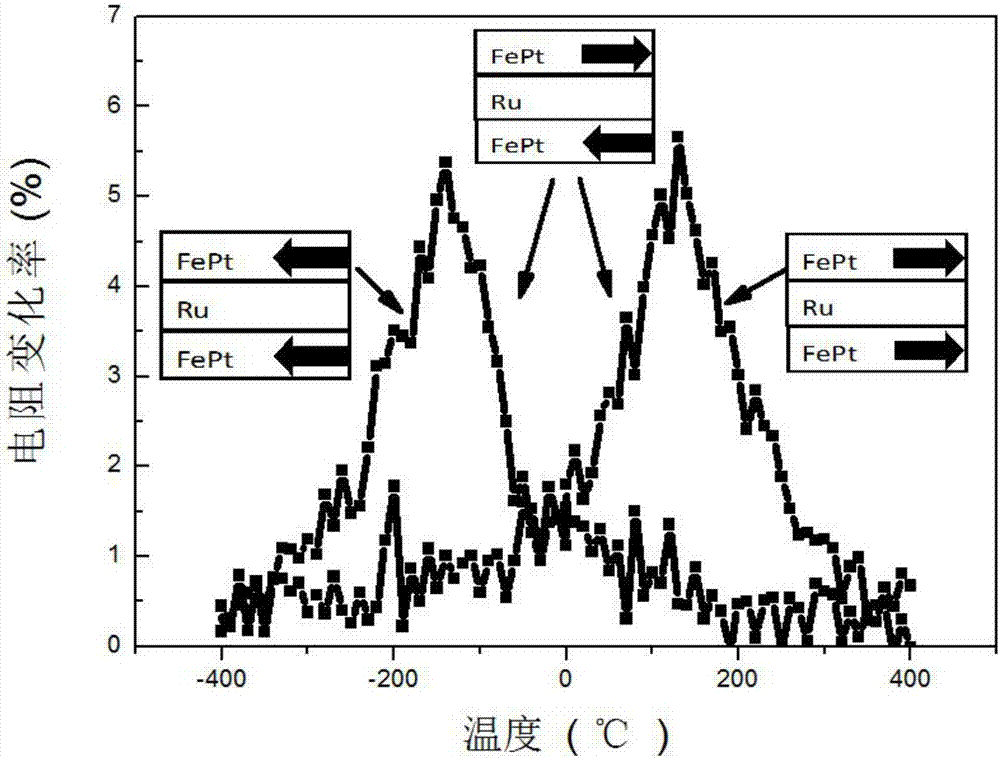

[0021] figure 1 The preparation conditions of the sample are as follows: firstly, the Cu-Zn-Al substrate is subjected to pre-stretching, surface acid treatment and surface polishing treatment, wherein the thickness of the substrate is 0.5 mm, and the pre-stretch amount is 15%; the surface acid treatment The pH value is 6, and the acidification time is 3 minutes; surface polishing treatment: mechanical polishing and chemical polishing, and the surface roughness after polishing is 0.5 nanometers. After the treatment, the surface is cleaned with acetone and alcohol to obtain a Cu-Zn-Al surface with a clean surface. Then, utilize magnetron sputtering method, on the Cu-Zn-Al substrate after above-mentioned treatment, deposit FePt atom (thickness is ), Ru atoms (thickness is ), FePt atoms (thickness is ), Ta atoms (thickness is ), thus preparing Cu-Zn-Al substrate / Multi-layer film, the background vacuum before sputtering deposition is 1×10 - 5 Pa, the argon pressure du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com