Solid sodium battery and preparation method thereof

A sodium battery and solid-state electrolyte technology, applied in the field of materials, can solve problems such as high cost and complex processing methods, and achieve high production efficiency, low cost, and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

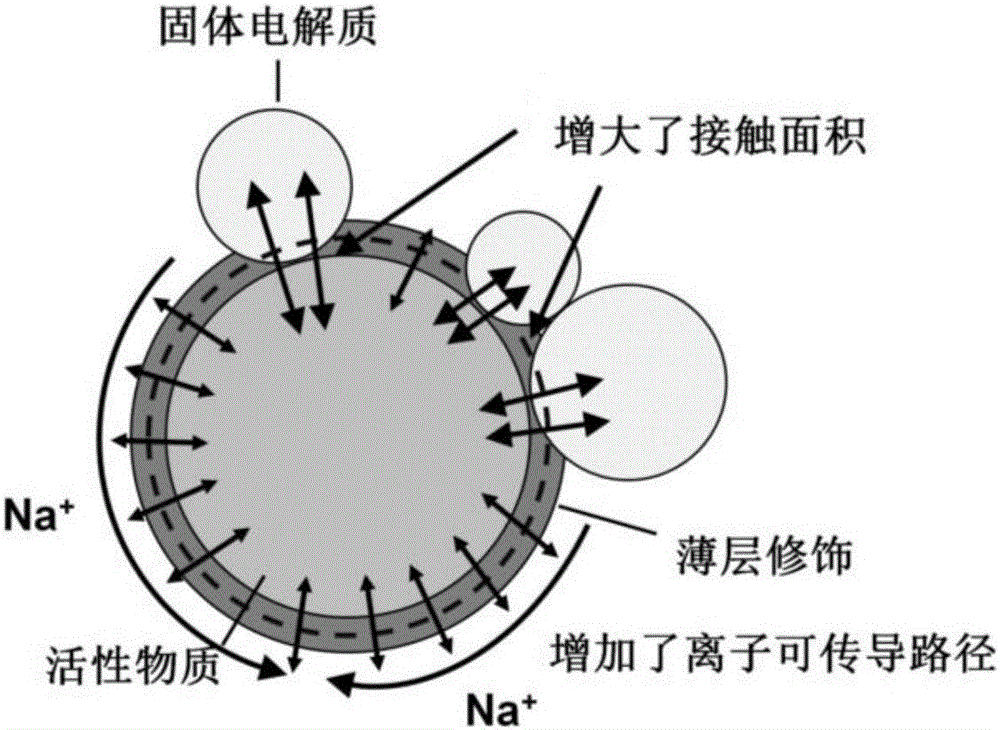

Embodiment 1

[0045] Embodiment 1 of the present invention provides a solid sodium battery, which includes a positive electrode, a negative electrode and a solid electrolyte, wherein the positive electrode is modified with a thin layer of a sodium ion conductive material. That is to say, in addition to the positive electrode, negative electrode and solid electrolyte, the solid-state sodium battery also includes a sodium ion conductive material, which is used as a thin layer modification material for the positive electrode in the battery. Preferably, the thin-layer modification material used in the solid-state sodium battery is electrolyte, molten salt or ionic liquid. in,

[0046] Preferably, the electrolyte is NaClO 4 / EC-DEC, NaClO 4 / PC, NaClO 4 / EC-DMC, NaClO 4 / EC-DEC-PC, NaClO 4 / EC-DMC-PC, NaPF 6 / PC, NaPF 6 / EC-DEC, NaFSI / EC-DMC-PC, NaPF 6 / EC-DEC-PC, NaPF 6 / EC-DMC-PC, NaFSI / EC-DEC, NaPF 6 / EC-DMC, NaFSI / EC-DMC, NaFSI / EC-DEC-PC or NaFSI / PC, etc.;

[0047] Preferably, the...

Embodiment 2

[0052] Embodiment 2 of the present invention provides a solid-state sodium battery. The solid-state sodium battery includes a positive electrode, a negative electrode and a solid electrolyte, wherein both the positive electrode and the negative electrode are modified with thin layers of sodium ion conductive materials. That is to say, in addition to the positive electrode, negative electrode and solid electrolyte, the solid-state sodium battery also includes a sodium ion conductive material, which is used as a thin-layer modification material for the positive electrode and the negative electrode in the battery. Preferably, the thin-layer modification material used in the solid-state sodium battery is electrolyte, molten salt or ionic liquid. in,

[0053] Preferably, the electrolyte is NaClO 4 / EC-DEC, NaClO 4 / PC, NaClO 4 / EC-DMC, NaClO 4 / EC-DEC-PC, NaClO 4 / EC-DMC-PC, NaPF 6 / PC, NaPF 6 / EC-DEC, NaFSI / EC-DMC-PC, NaPF 6 / EC-DEC-PC, NaPF 6 / EC-DMC-PC, NaFSI / EC-DEC, Na...

Embodiment 3

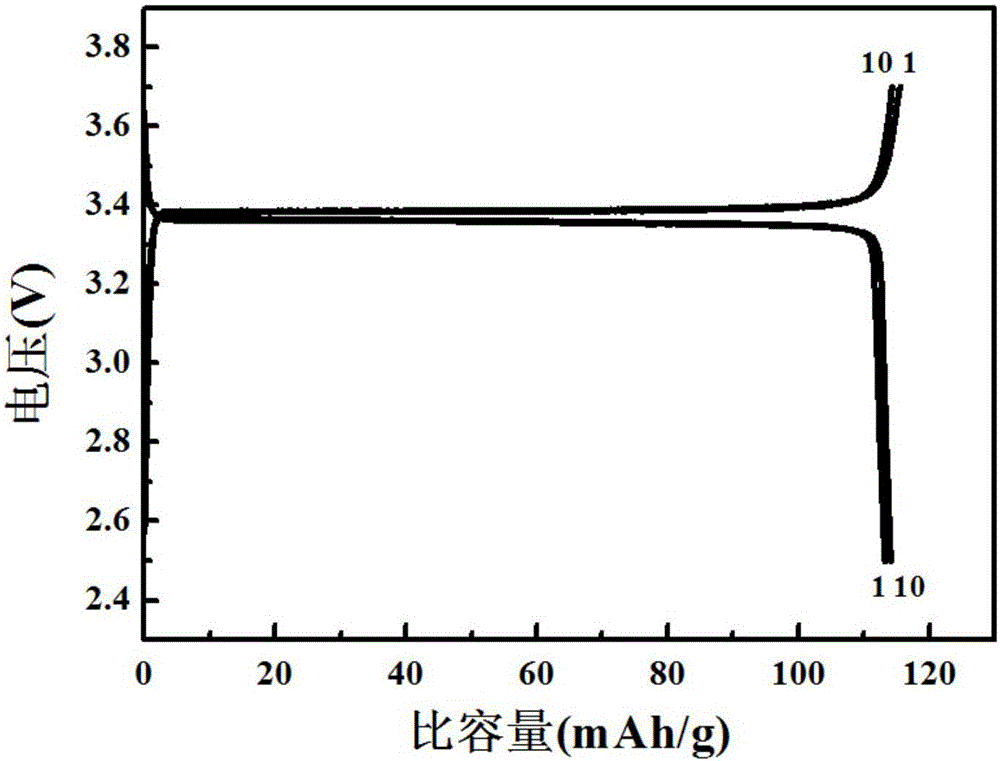

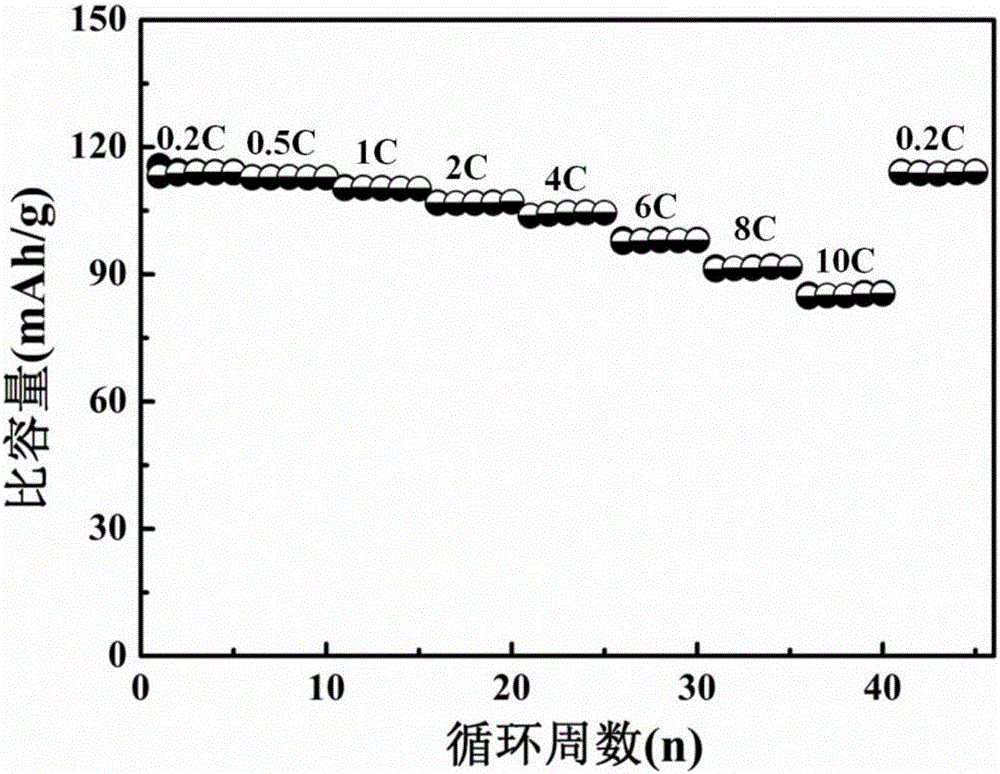

[0059] This example provides the preparation method of the solid-state sodium battery in Example 1. Metal Na is used as the negative electrode of the solid-state sodium battery, and the positive electrode is modified with a thin layer, which is carried out when assembling the battery. The preparation process is as follows:

[0060] Mix the positive electrode active material with electrolyte powder, conductive carbon black, and binder in a certain proportion, grind or stir evenly, and apply it to the surface of the ceramic sheet; dry it at room temperature to 120°C, and transfer it to a glove box; put the metal Na is pasted on the other side of the ceramic sheet, and a thin layer of modification material is dropped on the positive side for encapsulation. Preferably, during the preparation process, the mass of the thin-layer modification material is 1-50% of the total mass of the positive electrode.

[0061] The preparation method of the solid-state sodium battery provided in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com