Method of synthesizing MoS2@graphene composite nanomaterial

A graphene composite and nano-material technology, applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the complex synthesis process of composite materials and other problems, and achieve high uniformity of material loading, simple process, and controllable conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] a. Weigh 30 mg of pyrolysis-reduced graphene oxide, and ultrasonically disperse it in 60 ml of pre-prepared 10 mM tris buffer;

[0019] b. Add 90 mg of dopamine to the mixed solution of a above, stir for 2 hours, and fully dissolve;

[0020] c. Add 0.2g of sodium molybdate to the above solution b, and continue to stir for 1h; then add 0.4g of thiourea, and stir for 1h;

[0021] d. Pour the reacted mixed solution into a polytetrafluoroethylene-lined autoclave and react at 200°C for 24 hours;

[0022] e. After the reaction is completed, the product is taken out from the reaction kettle, centrifuged, washed repeatedly with deionized water and ethanol, dried in vacuum at 60°C overnight, and calcined at 600°C for 2 hours in a nitrogen atmosphere to obtain MoS prepared by the present invention 2 @graphene composite nanomaterials.

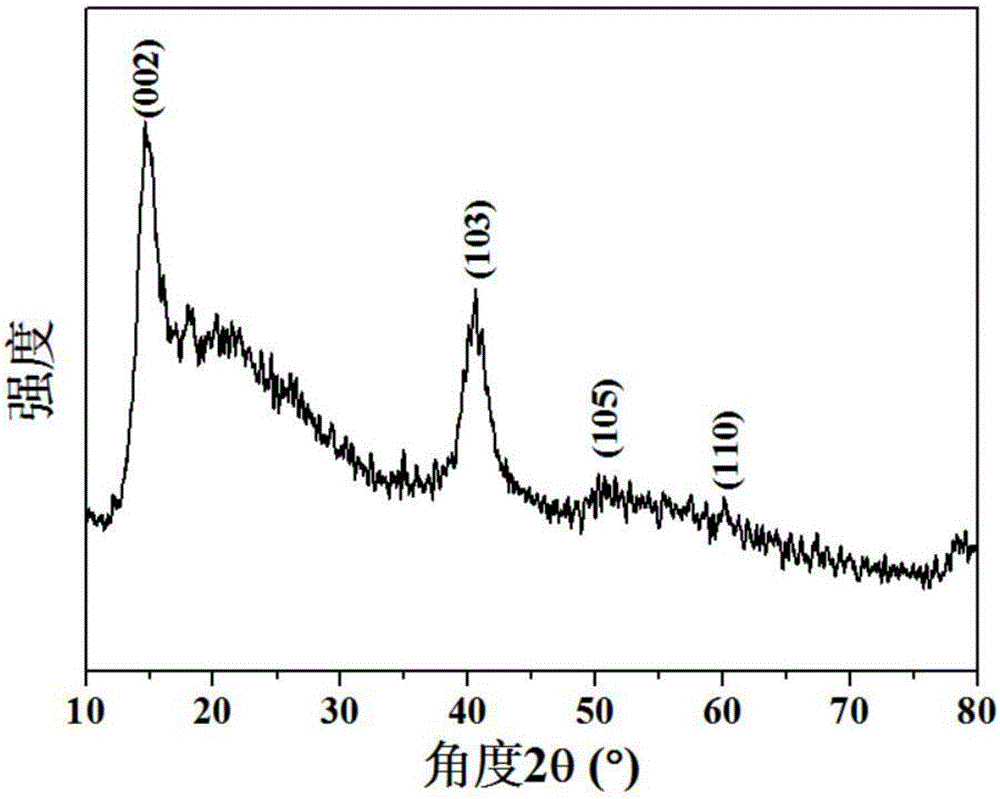

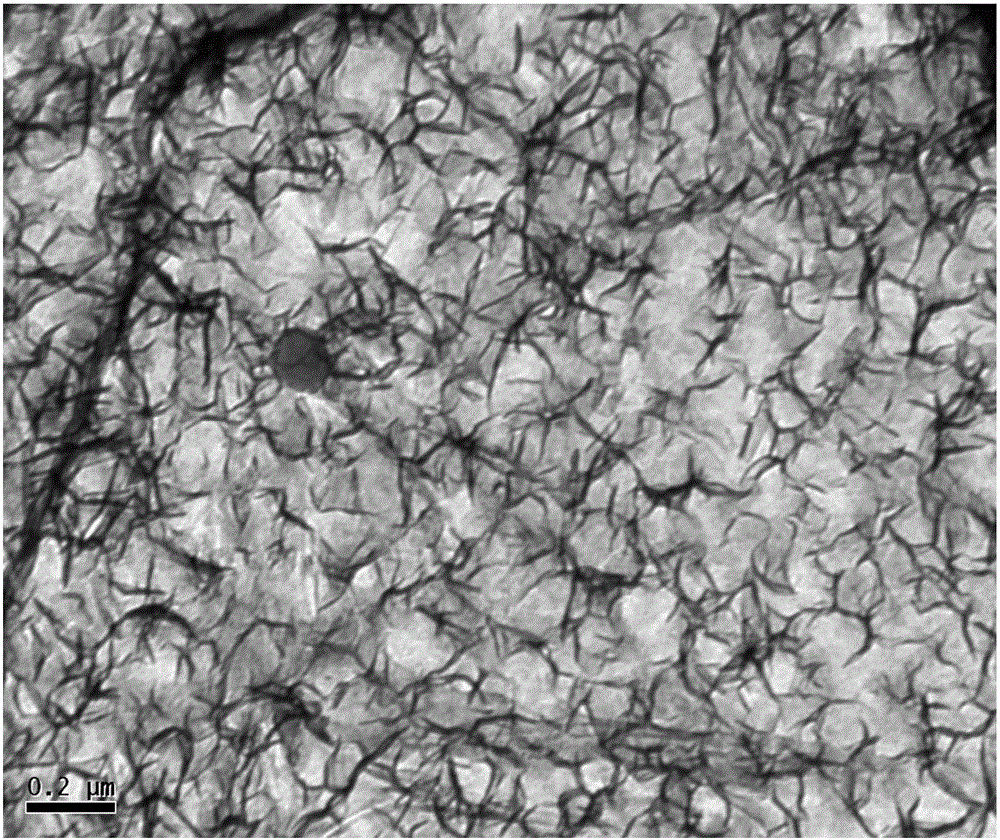

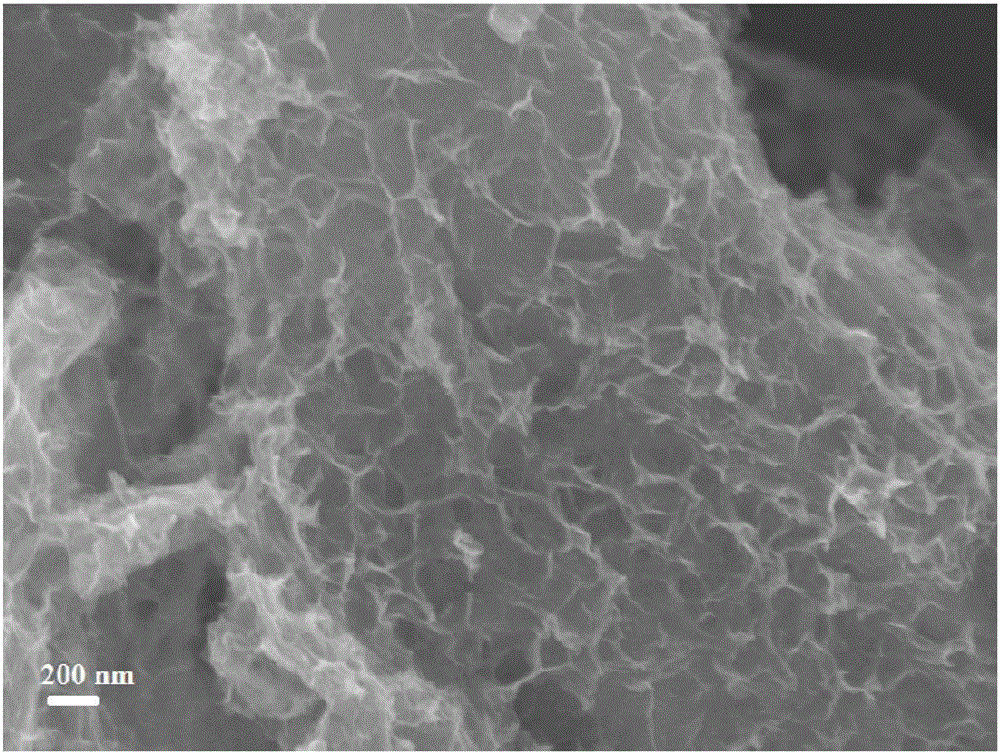

[0023] The physical properties of the obtained samples were characterized, and some of the results are shown in the accompanying drawings. Fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com