Self heat-insulation and fireproof building material

A fireproof building and self-insulation technology, applied in the field of building materials, can solve the problems of poor fireproof performance, unsatisfactory thermal insulation effect, easy collapse, etc., and achieve the effects of convenient construction, improved fire resistance and reasonable formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

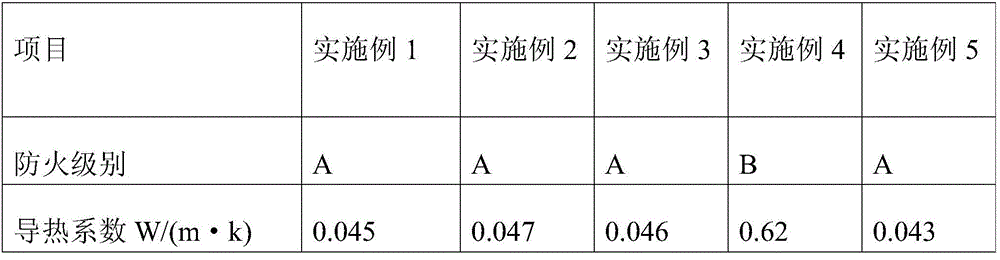

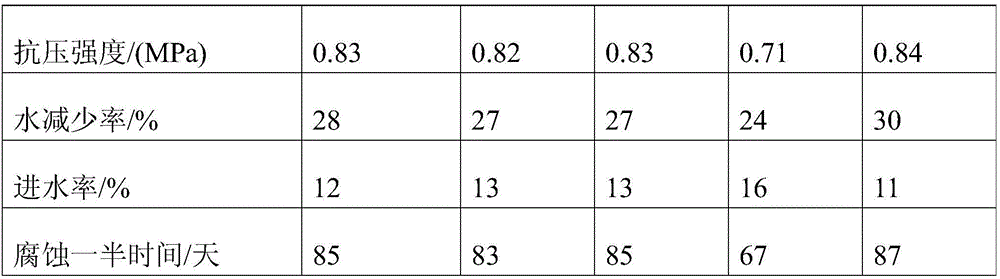

Examples

Embodiment 1

[0022] A self-insulating fire-proof building material. The raw materials for preparing the self-insulating fire-proof building material include: 30 parts of glass fiber, 30 parts of polystyrene particles, 100 parts of high alumina cement, 20 parts of asbestos, PTFE 13 parts of ethylene, 8 parts of lithium chloride, 7 parts of polyamide (nylon 46 is used in this implementation), 30 parts of ceramic cotton, 20 parts of calcined kaolin, 12 parts of ferrous sulfate, 12 parts of magnesium oxide, 11 parts of silica fume, magnesium sulfate 6 parts, 4 parts of sodium lignosulfonate, 6 parts of sodium lauryl sulfate, 14 parts of flame retardant, 3 parts of foam stabilizer, 16 parts of bauxite, 7 parts of nano rubber powder, hydroxypropyl methylcellulose 2 parts of prime, 11 parts of polyacrylamide, 17 parts of sodium alginate and 8 parts of polyethylene glycol (using PEG-2000).

[0023] The polystyrene particles are expanded polystyrene foam particles made by expanding and foaming expa...

Embodiment 2

[0032] A self-insulating fire-proof building material. The raw materials for preparing the self-insulating fire-proof building material include: 20 parts of glass fiber, 50 parts of polystyrene particles, 150 parts of high alumina cement, 10 parts of asbestos, and PTFE. 5 parts of ethylene, 5 parts of lithium chloride, 10 parts of polyamide (nylon 66 is used in this implementation), 10 parts of ceramic cotton, 10 parts of calcined kaolin, 10 parts of ferrous sulfate, 5 parts of magnesium oxide, 20 parts of silica fume, magnesium sulfate 5 parts, 1 part of sodium lignosulfonate, 1 part of sodium fatty alcohol polyoxyethylene ether sulfate, 20 parts of flame retardant, 1 part of foam stabilizer, 30 parts of bauxite, 15 parts of nano rubber powder, hydroxypropyl methyl 1 part of base cellulose, 5 parts of polyacrylamide, 30 parts of sodium alginate and 5 parts of polyethylene glycol (using PEG-2000).

[0033] The polystyrene particles are expanded polystyrene foam particles made ...

Embodiment 3

[0043]A self-insulating fire-proof building material. The raw materials for preparing the self-insulating fire-proof building material include: 50 parts of glass fiber, 20 parts of polystyrene particles, 120 parts of high alumina cement, 30 parts of asbestos, PTFE 20 parts of ethylene, 15 parts of lithium chloride, 5 parts of polyamide (nylon 46 is used in this implementation), 50 parts of ceramic cotton, 50 parts of calcined kaolin, 20 parts of ferrous sulfate, 20 parts of magnesium oxide, 5 parts of silica fume, magnesium sulfate 10 parts, 10 parts of sodium lignosulfonate, 10 parts of sodium lauryl sulfate, 10 parts of flame retardant, 5 parts of foam stabilizer, 10 parts of bauxite, 5 parts of nano rubber powder, hydroxypropyl methylcellulose 5 parts of prime, 20 parts of polyacrylamide, 10 parts of sodium alginate and 5 parts of polyethylene glycol (using PEG-3000).

[0044] The polystyrene particles are expanded polystyrene foam particles made by expanding and foaming ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com