Preparation method of EVOH (ethylene-vinyl alcohol) copolymer

A vinyl alcohol copolymer and ethylene technology, applied in the field of preparation of ethylene-vinyl alcohol copolymer, can solve the problems of low reaction efficiency, difficult control of reaction speed, unstable production, etc., and achieves good transparency, controllable reaction rate, polymerization The effect of high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

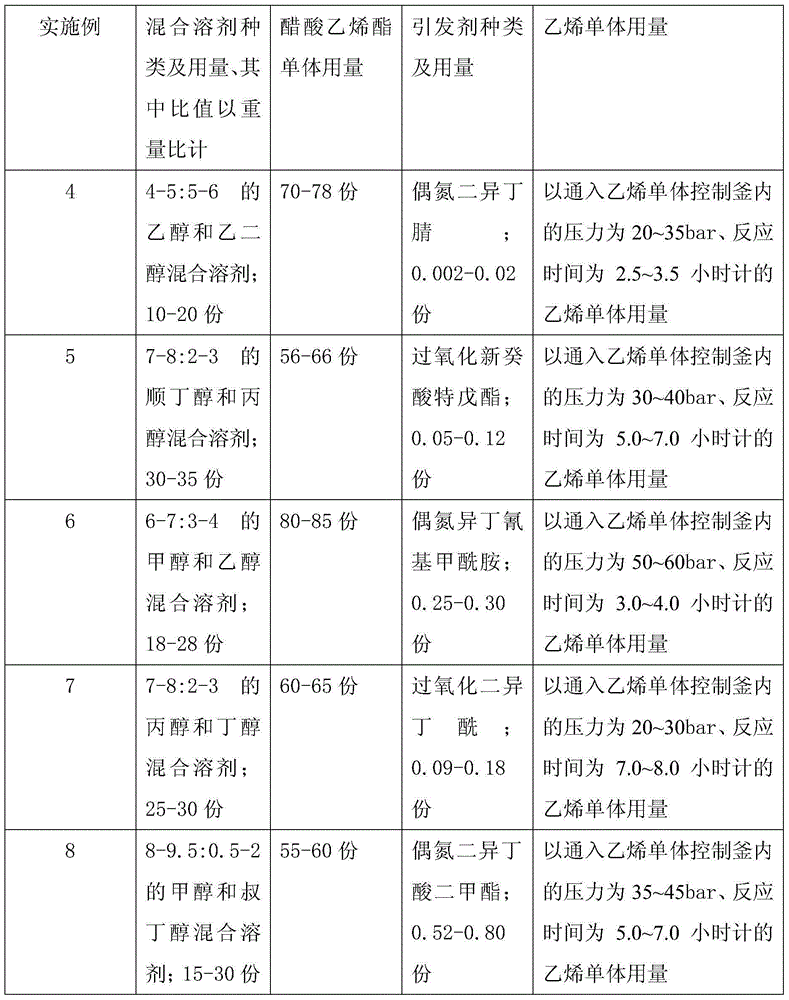

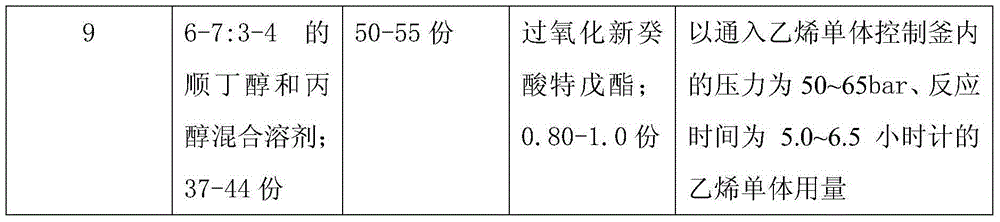

Examples

Embodiment 1

[0030] A preparation method of ethylene-vinyl alcohol copolymer, using methanol / tert-butanol mixed solvent, vinyl acetate monomer, popenyl peroxyneodecanoate initiator and ethylene monomer as raw materials, deoxidizing the raw materials, and Internal replacement, initial feeding, polymerization reaction, blowing out residual sheet and saponification steps to prepare ethylene-vinyl alcohol copolymer; the deoxygenation of the raw materials is to add vinyl acetate monomer, solvent and initiator into the mixing tank and stir, while stirring Nitrogen is mixed evenly and replaced so that the oxygen content in the system is less than 1.0*10 -3 mol / L; The polymerization reaction efficiency is greatly improved by adopting the above raw material deoxygenation steps, and the conversion rate reaches more than 60%.

Embodiment 2

[0032] A preparation method of ethylene-vinyl alcohol copolymer, which uses ethanol / ethylene glycol mixed solvent, vinyl acetate monomer, azobisisobutyronitrile initiator and ethylene monomer as raw materials, deoxidizes the raw materials, and replaces them in a kettle , initial feeding, polymerization reaction, blowing out residual single and saponification steps to prepare ethylene-vinyl alcohol copolymer; said raw material deoxygenation is to add vinyl acetate monomer, solvent and initiator to the mixing tank and stir, and feed nitrogen gas while stirring Uniform, replacement, so that the oxygen content in the system is less than 1.0*10 -3 mol / L; the replacement in the kettle uses 5-10bar N 2 The reactor was replaced twice, and then replaced twice with 5-10 bar ethylene, and each time the replacement lasted for 5-9 minutes respectively.

Embodiment 3

[0034] A preparation method of ethylene-vinyl alcohol copolymer, as follows:

[0035] 1) Deoxidation of raw materials

[0036] Add the vinyl acetate monomer, the above-mentioned solvent and the initiator into the mixing tank, start the stirring, pass in nitrogen gas while stirring, mix evenly, and fully replace, so that the oxygen content in the system is less than 1.0*10 -3 mol / L;

[0037] 2), replacement in the kettle

[0038] Use 5~10bar N 2 Replace the reactor twice, and then replace it twice with 5-10 bar ethylene, each time for 5-9 minutes;

[0039] 3), initial feeding

[0040] Add the above-mentioned vinyl acetate, methanol / ethanol mixed solvent and azobisisobutyronitrile initiator deoxygenated from raw materials into the reaction kettle through a pump, and stir at room temperature at 60-180rpm for 5-10min;

[0041] 4), polymerization reaction

[0042] Feed ethylene monomer, control the pressure at 10-60bar, start timing when the temperature in the kettle is 40-80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxygen transmission rate | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

| Chroma | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com