Waterproof oil-proof agent for paper products and preparation method and application thereof

A waterproof and oil-repellent agent and paper product technology, applied in the direction of water-repellent agent addition, paper, papermaking, etc., can solve the problems of large addition ratio, poor stability, insufficient effect of waterproof and oil-repellent agent, etc., and achieve the effect of eliminating volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: synthetic example 1

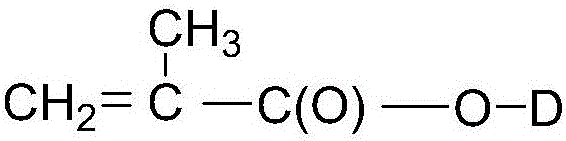

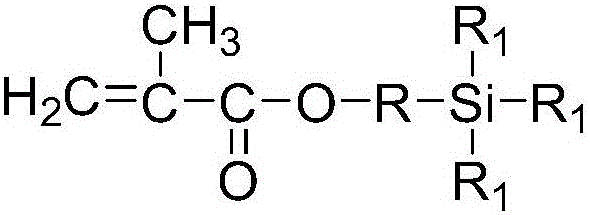

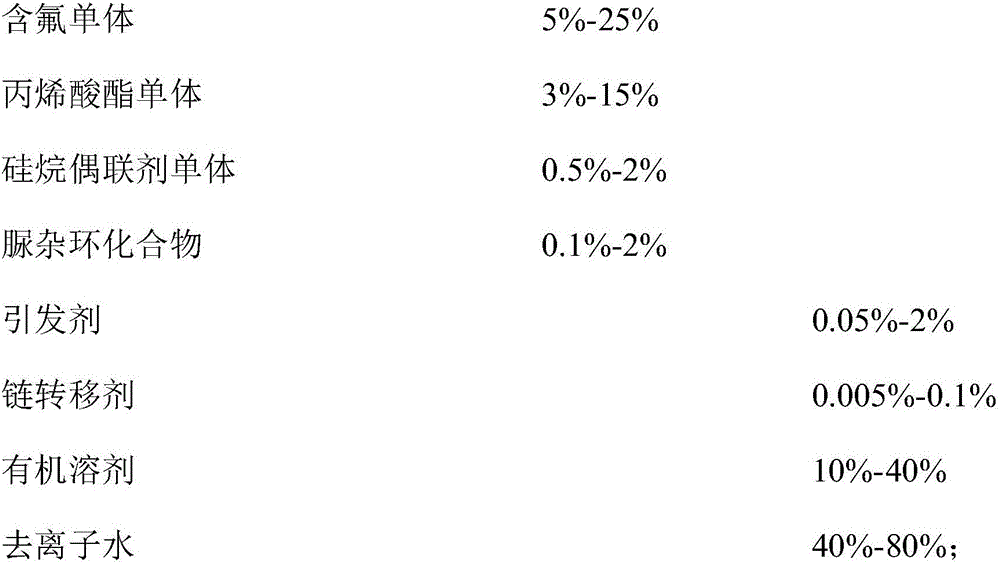

[0086] At room temperature, 58 g of acetone was added as a solvent into a 500 ml reaction kettle equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure funnel and a nitrogen replacement device. Turn on the stirring, and mix 10.5g of fluorine-containing monomer (CF 3 (CF 2 ) 3 CH 2 CH 2 OCOC (CH 3 )=CH 2 ) into the reactor. Then add 0.5g urea heterocyclic compound hydroxyethyl ethylene urea and 1.78g methacryloxypropyltrimethoxysilane containing double bonds, then 7.9g butyl acrylate and 3.4g glycidyl methacrylate After the esters are mixed, slowly drop them into the reaction kettle with a constant pressure funnel. Then 0.14g of dodecyl mercaptan was diluted with a small amount of acetone solvent and slowly dropped into the reactor from a constant pressure funnel. Next, use a small amount of acetone as a solvent to dissolve 0.74g of azobisisobutyronitrile, heat to 50-85°C to promote the dissolution pro...

Embodiment 2

[0087] Embodiment 2: synthetic example 2

[0088] At room temperature, 30 g of acetone was added as a solvent into a 500 ml reaction kettle equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure funnel and a nitrogen replacement device. Open stirring, under low speed, the fluorine-containing monomer (CF) of 49g 3 (CF 2 ) 5 CH 2 CH 2 CH 2 OCOC (CH 3 )=CH 2 ) into the reactor, then add 0.77g urea heterocyclic compound pseudothiohydantoin containing double bonds and 2.47g methacryloxypropylmethyldimethoxysilane, then add 15.3g of formazan After mixing ethyl ethyl methacrylate and 8.9 g of isobornyl methacrylate, they were slowly dropped into the reaction kettle with a constant pressure funnel. Then 0.2 g of mercaptoethanol was diluted with a small amount of acetone solvent and slowly dropped into the reaction kettle from a constant pressure funnel. Next, use a small amount of acetone as a solvent to dissolve 0.74g of azobisisobutyronitrile, heat ...

Embodiment 3: Synthetic example 3

[0090] At room temperature, 60 g of acetone was added as a solvent into a 500 ml reaction kettle equipped with a stirrer, a thermometer, a reflux condenser, a constant pressure funnel and a nitrogen replacement device. Start stirring, under low speed, the fluorine-containing monomer (CF) of 23g 3 (CF 2 ) 3 CH 2 CH 2 OCOCH=CH 2 ) into the reaction kettle, then add 0.5g urea heterocyclic compound α-(2-furanoyl) ureidophenylacetic acid and 2.465g methacryloxypropylmethyldiethoxysilane containing double bonds, Then, 11.18 g of dimethylaminoethyl methacrylate was slowly dropped into the reaction kettle with a constant pressure funnel. Then, 0.12 g of mercaptoethanol was diluted with a small amount of acetone solvent and slowly dropped into the reaction kettle through a constant pressure funnel. Next, use a small amount of acetone as a solvent to dissolve 0.74g of azobisisobutyronitrile, heat to 50-85°C to promote the dissolution process, and add it to a constant pressure funn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com