Low-VOC glass fiber reinforced polypropylene halogen-free flame-retardant composite and application

A flame retardant composite material and polypropylene technology, which is applied in the field of low VOC glass fiber reinforced polypropylene halogen-free flame retardant composite materials, can solve the problems of VOC, a large number of molten droplets, and the ability discount of adsorption and degradation at the same time, and achieve lasting and effective Secondary pollution, no secondary pollution, the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

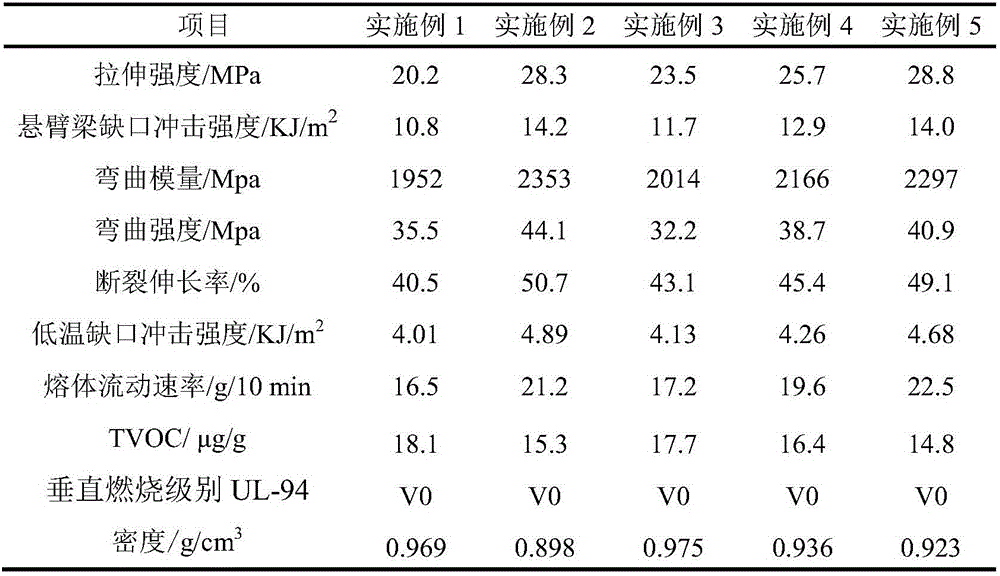

Examples

Embodiment 1

[0025] This embodiment provides a low-VOC glass fiber reinforced polypropylene halogen-free flame-retardant composite material, which includes the following components in parts by weight:

[0026] 65 parts of polypropylene, 4.5 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 1 part, 5-25mm long glass fiber 21.5 parts, talcum powder 3.5 parts, antioxidant 1010 0.2 part, anti-ultraviolet additive CYASORB UV-V680 0.3 part, ammonium polyphosphate 0.8 parts, 0.2 parts of zinc borate, 3 parts of VOC inhibitors, wherein the VOC inhibitors include titanium dioxide quantum dots, attapulgite, sepiolite, diatomite and tourmaline with 10-20nm surface doped with silver nanoclusters, wherein the nano The mass ratio of photocatalyst, attapulgite, sepiolite, diatomite and tourma...

Embodiment 2

[0029] A low-VOC glass fiber reinforced polypropylene halogen-free flame-retardant composite material, the composite material includes the following components in parts by weight:

[0030] 35 parts of polypropylene, 5 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 3 parts, 5-25mm long glass fiber 45 parts, talcum powder 5 parts, antioxidant 0.5 part, this antioxidant is made of antioxidant 1010 and antioxidant 168 according to mass ratio 2 : 1 compound, 0.3 parts of anti-ultraviolet additive CYASORB UV-3808PP5, 1.5 parts of N, N-p-phenylenediamine (2-hydroxyl) tetraethyl dibenzyl phosphonate, 0.5 parts of zinc borate, VOC suppression 3 parts, wherein the VOC inhibitor includes titanium dioxide quantum dots, attapulgite, sepiolite and diatomite doped with silver na...

Embodiment 3

[0033] A low-VOC glass fiber reinforced polypropylene halogen-free flame-retardant composite material, the composite material includes the following components in parts by weight:

[0034] 70 parts of polypropylene, 6 parts of hollow glass microspheres, wherein the particle diameter of the hollow glass microspheres is 1-3mm, and the surface of the hollow glass microspheres is repeatedly dipped and coated with PP-g-MAH (grafting ratio of 2.5-3.0wt %, melt index is 120-200g / 10min) 2.3 parts, 5-25mm long glass fiber 15 parts, antioxidant 168 0.2 part, anti-ultraviolet additive CYASORB UV-V680 0.5 part, dimethyl methylphosphonate 1.5 parts , 4 parts of VOC inhibitors, wherein the VOC inhibitors include titanium dioxide quantum dots, attapulgite, sepiolite, and diatomite doped with silver nanoclusters on the surface of 10-20nm, wherein nano-photocatalyst, attapulgite, sepiolite , The mass ratio of diatomite is 15:30:40:15.

[0035] Above-mentioned raw material is produced accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com