Refrigerant oil composition and application thereof

A technology of refrigeration oil and composition, applied in the field of lubricating oil, can solve the problems of low viscosity index, poor anti-wear performance, inappropriate anti-wear performance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

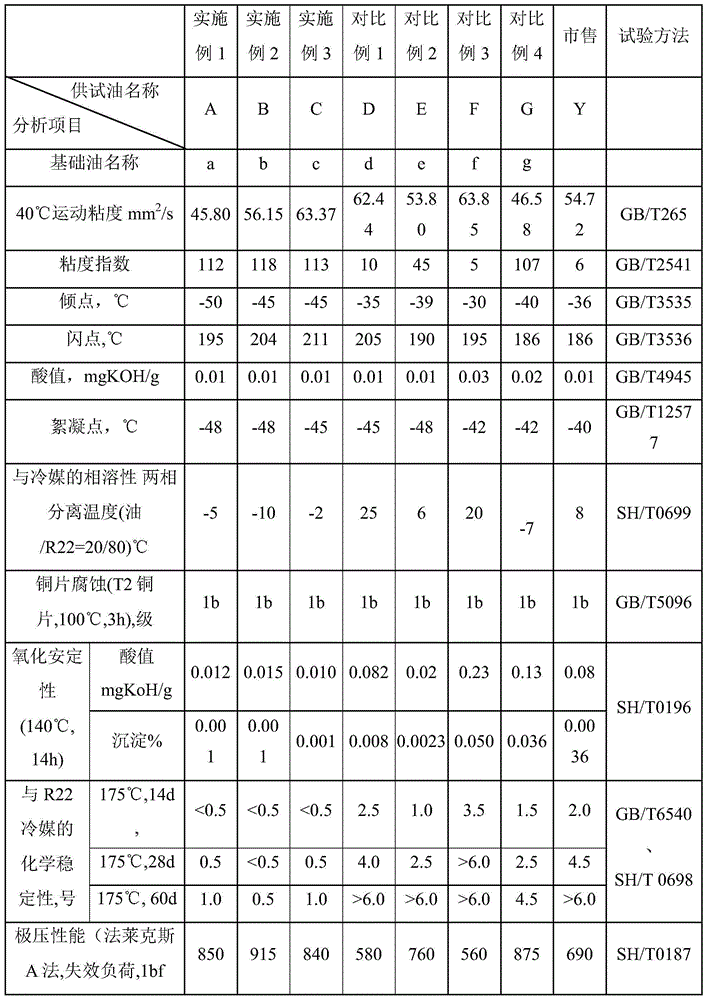

Examples

Embodiment 1

[0041] Use 55% naphthenic high-pressure hydrogenation to reduce second-line mineral oil (from Karamay Petrochemical Company), add 15% boiling point above 250 ° C, 100 ° C kinematic viscosity 7.42mm 2 / s, pour point -42°C, alkylbenzene synthetic lubricating oil base oil with a viscosity index of 105 (from commercially available Dopp Chemical products), and then add 30% of the flash point above 200°C, and the kinematic viscosity at 100°C is 8.51mm 2 / s, pour point -56°C, oil-soluble polyether base oil (from commercially available Dow Chemical products) with a viscosity index of 175, adjusted to a kinematic viscosity of 45.65mm at 40°C 2 / s base oil a.

Embodiment 2

[0043] Use 45% naphthenic high-pressure hydrogenation to reduce the third-line mineral oil (from Karamay Petrochemical Company), add 15% boiling point above 250 ° C, 100 ° C kinematic viscosity 7.42mm 2 / s, pour point -42°C, alkylbenzene synthetic lubricating oil base oil with a viscosity index of 105 (from commercially available Dopp Chemical products), and then add 40% of the flash point above 200°C, and the kinematic viscosity at 100°C is 8.51mm 2 / s, pour point -56°C, oil-soluble polyether base oil (from commercially available Dow Chemical products) with a viscosity index of 175, adjusted to a kinematic viscosity of 56.32mm at 40°C 2 / s base oil b.

Embodiment 3

[0045] Use 60% naphthenic high-pressure hydrogenation to reduce the third-line mineral oil (from Karamay Petrochemical Company), add 20% with a boiling point above 250°C, and a kinematic viscosity of 7.42mm at 100°C 2 / s, pour point -42°C, alkylbenzene synthetic lubricating oil base oil with a viscosity index of 105 (from commercially available Dopp Chemical products), and then add 20% flash point above 200°C, 100°C kinematic viscosity 8.51mm 2 / s, pour point -56°C, viscosity index 175 oil-soluble polyether base oil (from commercially available Dow Chemical products), adjusted to 40°C kinematic viscosity 63.15mm 2 / s base oil c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com