Mesoporous La0.8Sr0.2CoO3 loaded nanometer CeO2 catalyst as well as preparation method and application thereof

A catalyst and mesoporous technology, applied in the field of oxide-supported catalysts, can solve the problems that harmful components of cold-start exhaust gas cannot be well treated, limit the practical application of catalysts, and deactivate catalysts, and achieve good low-temperature catalytic activity and thermal stability. properties, improving low-temperature catalytic activity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Preparation of mesoporous La with large specific surface area 0.8 Sr 0.2 CoO 3 ,Specific steps are as follows:

[0053] 1) Take a clean beaker, pour 200ml deionized water, add 0.016mol La(NO 3 ) 3 ·6H 2 O, 0.004mol Sr(NO 3 ) 2 , 0.02mol Co(NO 3 ) 2 ·6H 2 O, stir to dissolve, add 0.03mol citric acid monohydrate to the above-mentioned nitrate solution, stir to dissolve, magnetically stir for 12 hours at room temperature, and record it as solution A.

[0054] 2) Take another clean beaker, pour 200ml of deionized water into it, add 0.03mol of citric acid monohydrate and stir to dissolve, then add 2.4g (equivalent to 0.04mol) of SBA-15, sonicate for 15min, stir magnetically at room temperature for 12h, record it as a solution B; The template agent SBA-15 used in this example is prepared according to the literature (P.D.Yang, D.Y Zhao, et.al.Nature, 1998, 396:152~155), and the specific surface area is 840m 2 / g, the pore diameter is 6nm, the pore volume is 1.08cm ...

Embodiment 2

[0061] Only to the catalyst La that embodiment 1 makes 0.8 Sr 0.2 CoO 3 Perform hydrothermal treatment without loading CeO 2 ,Specific steps are as follows:

[0062] 1) Weigh 3.2g NaOH and dissolve it in 80ml deionized water, stir and dissolve at room temperature to obtain a NaOH solution with a concentration of 1mol / L, add 1.2g of the mesoporous La in Example 1 0.8 Sr 0.2 CoO 3 Stir well, and ultrasonically disperse for 30 minutes to obtain a dispersion;

[0063] 2) Put the dispersion liquid obtained in step 1) in a reaction kettle, conduct a hydrothermal reaction at 100°C for 24 hours, take out, filter, wash until neutral, and dry at 80°C for 12 hours to obtain a solid;

[0064] 3) The solid obtained in step 2) is ground; in a muffle furnace, the heating rate is raised to 400° C. for 2 hours at a rate of 2° C. / min, and a black powder product is obtained, that is, La 0.8 Sr 0.2 CoO 3 .

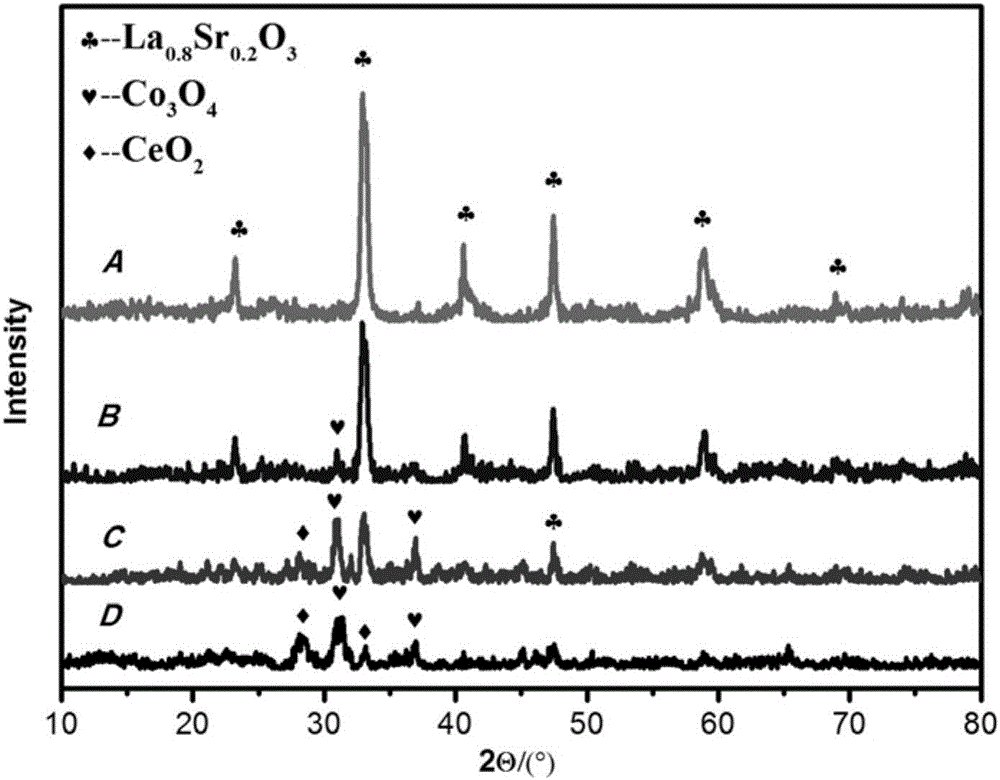

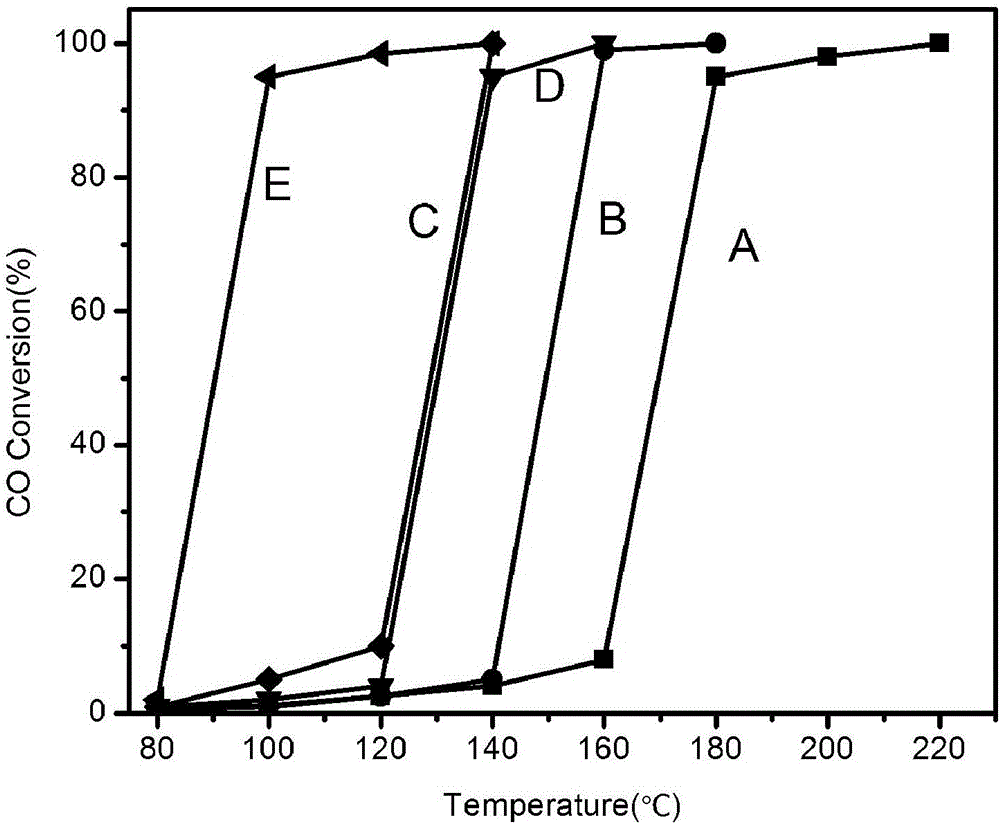

[0065] figure 1 The middle B curve is the mesoporous La obtained in this example...

Embodiment 3

[0068] Preparation of 10% CeO 2 / La 0.8 Sr 0.2 CoO 3 ,Specific steps are as follows:

[0069] 1) Weigh 0.3gCe(NO 3 ) 3 ·6H 2 O was dissolved in 10ml of deionized water, 3.2g of NaOH was weighed and dissolved in 50ml of deionized water, and the two solutions were mixed and stirred for 15min; then 1.2g of the mesoporous La prepared in Example 1 was added 0.8 Sr 0.2 CoO 3 Stir well, ultrasonic 1h to get the dispersion, add 20ml of deionized water to the dispersion, so that the concentration of NaOH is diluted to 1mol / L;

[0070] 2) Transfer the dispersion liquid into a reaction kettle, conduct a hydrothermal reaction at 100°C for 24 hours, take out the solid, filter, wash, and dry at 100°C for 8 hours to obtain a solid;

[0071] 3) Grind the solid obtained in step 2), and raise the temperature in a muffle furnace to 400°C at a rate of 2°C / min for 2 hours to obtain a black powder of 10% CeO 2 / La 0.8 Sr 0.2 CoO 3 .

[0072] figure 1 Middle C curve is the 10%CeO that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com