3D printing method of sodium alginate/polyvinyl chloride all-physically-crosslinked double-network hydrogel scaffold

A 3D printing and polyvinyl alcohol technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems that the mechanical properties cannot meet the needs of biological tissue materials, and do not solve the problem of good compatibility, so as to achieve excellent mechanical properties, Long service life and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

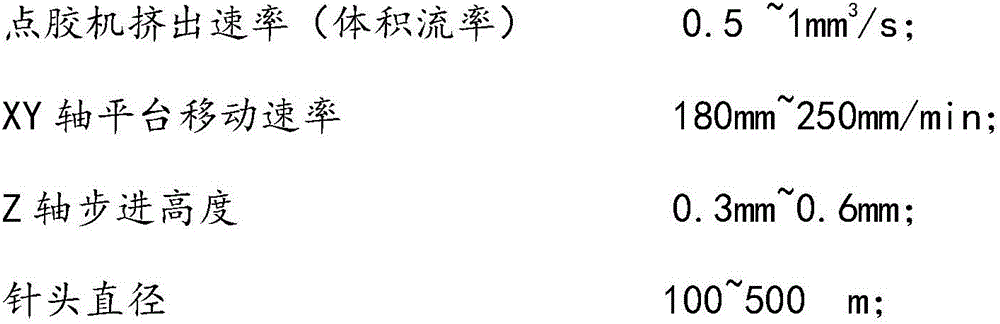

Method used

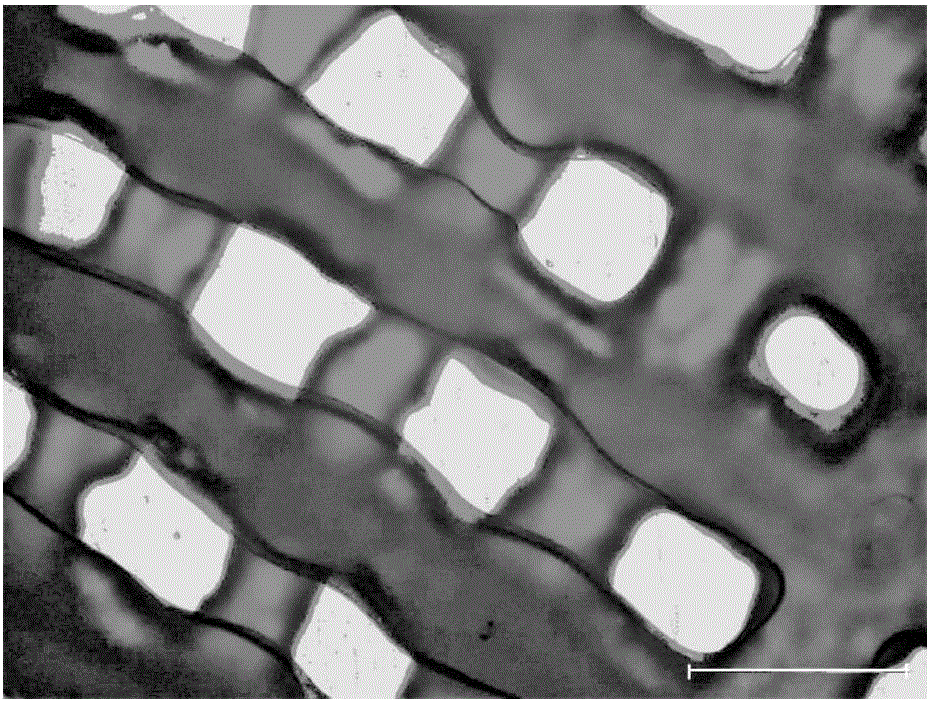

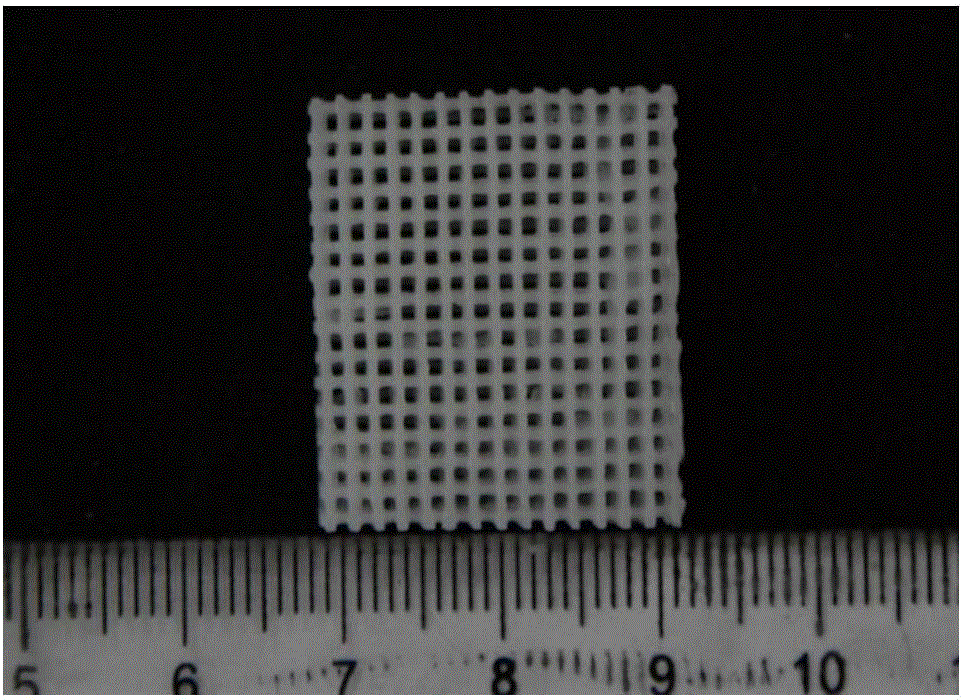

Image

Examples

Embodiment 1

[0042] Step 1: preparation of double network hydrogel scaffold material, including the following sub-steps:

[0043] Sub-step 1.1: Preparation of sol: Take 2g of sodium alginate (SA) and add it to 38g of deionized water to stir and disperse, place it in a constant temperature water at 65°C and reflux for 1 to 2 hours until the sodium alginate (SA) is completely dissolved to obtain seaweed Sodium acid solution;

[0044] Sub-step 1.2: Take 13.332g of polyvinyl alcohol (PVA) resin and add 40g of deionized water to stir and disperse, place in 95°C constant temperature water area to condense and reflux for 2 to 3 hours until the PVA is completely dissolved to obtain a PVA solution;

[0045] Sub-step 1.3: The SA solution in sub-step (1.1) and the PVA solution in sub-step (1.2) are fully mixed and stirred evenly to obtain a SA / PVA mixed solution.

[0046] Sub-step 1.4: Degas the mixed solution obtained in sub-step (1.3) in a vacuum oven at 95°C for 0.5h. After degassing is complete,...

Embodiment 2

[0054] Step 1: preparation of double network hydrogel scaffold material, including the following sub-steps:

[0055] Sub-step 1.1: Preparation of sol: Take 2g of sodium alginate (SA) and add it to 38g of deionized water to stir and disperse, place it in a constant temperature water at 65°C and reflux for 1 to 2 hours until the sodium alginate (SA) is completely dissolved to obtain seaweed Sodium acid solution;

[0056] Sub-step 1.2: Take 22.22g of polyvinyl alcohol (PVA) resin and add 66.667g of deionized water to stir and disperse, place in 95°C constant temperature water and reflux for 2 to 3 hours until the PVA is completely dissolved to obtain a PVA solution;

[0057] Sub-step 1.3: the SA solution in sub-step (1.1) is mixed with the PVA solution in sub-step (1.2) and stirred evenly to obtain a SA / PVA mixed solution.

[0058] Sub-step 1.4: Degas the mixed solution obtained in sub-step (1.3) in a vacuum oven at 95°C for 0.5h. After degassing is complete, slowly add 93.332g ...

Embodiment 3

[0065] Step 1: preparation of double network hydrogel scaffold material, including the following sub-steps:

[0066] Sub-step 1.1: Preparation of sol: Take 2g of sodium alginate (SA) and add it to 38g of deionized water to stir and disperse, place it in a constant temperature water at 65°C and reflux for 1 to 2 hours until the sodium alginate (SA) is completely dissolved to obtain seaweed Sodium acid solution;

[0067] Sub-step 1.2: Take 26.667g of polyvinyl alcohol (PVA) resin and add it to 80g of deionized water to stir and disperse, place it in a constant temperature water area at 95°C to condense and reflux for 2 to 3 hours until the PVA is completely dissolved to obtain a PVA solution;

[0068] Sub-step 1.3: The SA solution in sub-step (1.1) is fully mixed with the PVA solution in sub-step (1.2), and stirred evenly to obtain a homogeneous mixed solution.

[0069] Sub-step 1.4: Degas the mixed solution obtained in sub-step (1.3) in a vacuum oven at 95°C for 0.5h. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com