Mercaptan etherification catalyst and preparation method and application thereof

A catalyst and mercaptan technology, which is applied in the direction of sulfide preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of unstable activity, loss of effective carbon resources, etc., and achieve high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

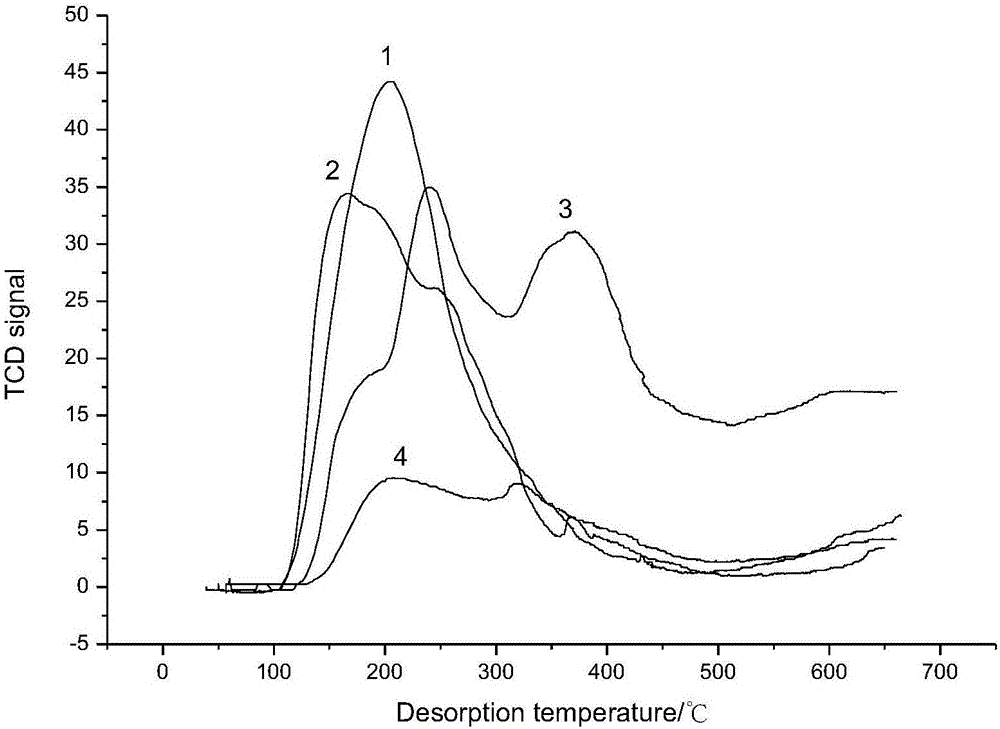

Image

Examples

Embodiment 1

[0027] Embodiment 1 of the present invention is used to prepare the catalyst of mercaptan etherification, and it is made of the raw material of following mass percentage: In step (1), be 55% NiO, 45% SiO 2 NiO-SiO 2 Powder; in the step (2), it is the NiO-SiO obtained in the 80% step (1) 2 Powder, 8% NiO, 12% Al 2 o 3 .

[0028] The preparation method comprises the following steps:

[0029] (1) Weigh 214.1g of nickel nitrate hexahydrate and 135g of silica sol, mix them with an appropriate amount of water, dry them supercritically, and roast at 550°C for 4 hours to obtain nickel oxide-silicon oxide powder.

[0030] (2) Weigh 80g of NiO-SiO prepared in the above step (1) 2 Powder, 8g NiO and 12g Al 2 o 3 Powder, added to dilute nitric acid aqueous solution, mixed and kneaded evenly, then extruded into strips;

[0031] (3) drying the extruded product in the above step (2) at 100° C., and roasting at 550° C. for 4 hours to obtain a finished mercaptan etherification catalyst...

Embodiment 2

[0033] Embodiment 2 of the present invention is used to prepare the catalyst of mercaptan etherification, and it is made by the raw material of following mass percentage: In step (1), be 60%NiO, 40%SiO 2 NiO-SiO 2 Powder; in the step (2), it is the NiO-SiO obtained in the 80% step (1) 2 Powder, 10% NiO, 10% Al 2 o 3 .

[0034] The preparation method comprises the following steps:

[0035] (1) Weigh 233.5g of nickel nitrate hexahydrate and 120g of silica sol, mix them with an appropriate amount of water, dry them supercritically, and roast at 550°C for 4 hours to obtain nickel oxide-silicon oxide powder.

[0036] (2) Weigh 80g of NiO-SiO prepared in the above step (1) 2 Powder, 10g NiO and 10g Al 2 o 3 Powder, added to dilute nitric acid aqueous solution, mixed and kneaded evenly, then extruded into strips;

[0037] (3) drying the extruded product in the above step (2) at 100° C., and roasting at 550° C. for 4 hours to obtain a finished mercaptan etherification catalyst...

Embodiment 3

[0039] Embodiment 3 of the present invention is used to prepare the catalyst of mercaptan etherification, and it is made of the raw material of following mass percentage: In step (1), be 75% NiO, 25% SiO 2 NiO-SiO 2 Powder; in the step (2), it is the NiO-SiO obtained in the 76% step (1) 2 Powder, 9.5% NiO, 14.5% Al 2 o 3 .

[0040] The preparation method comprises the following steps:

[0041] (1) Weigh 291.9g of nickel nitrate hexahydrate and 135g of silica sol, mix them with an appropriate amount of water, dry them supercritically, and roast at 550°C for 4 hours to obtain nickel oxide-silicon oxide powder.

[0042] (2) Weigh 76g of NiO-SiO prepared in the above step (1) 2 Powder, 9.5g NiO and 14.5g Al 2 o 3 Powder, added to dilute nitric acid aqueous solution, mixed and kneaded evenly, then extruded into strips;

[0043] (3) drying the extruded product in the above step (2) at 100° C., and roasting at 550° C. for 4 hours to obtain a finished mercaptan etherification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com