Supported palladium-based catalyst and preparation method and application thereof

A supported palladium and catalyst technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve problems such as deactivation, catalytic activity and selectivity decline, and achieve high selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

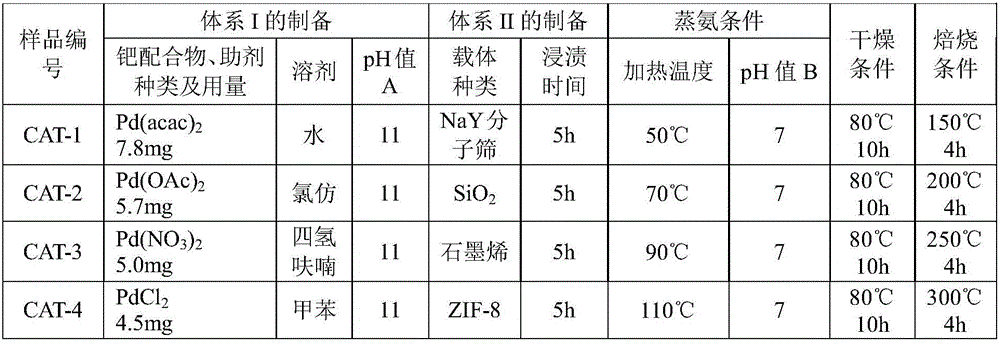

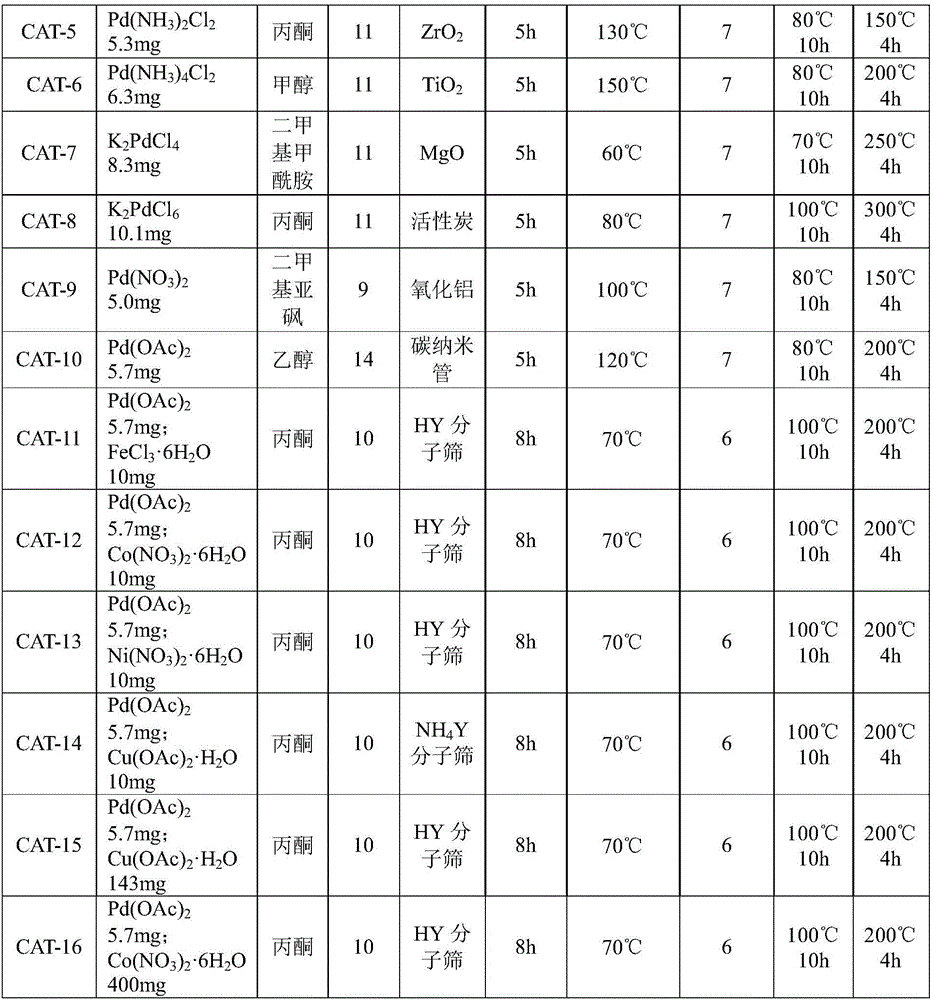

[0064] Example 1 Preparation of catalyst CAT-1~CAT-16

[0065] Disperse a certain amount of palladium-containing complex into 10 mL of solvent, add dropwise ammonia to adjust the pH of the system to A to obtain system I; add 1 g of carrier and stir and immerse at room temperature for a period of time to obtain system II; heat to the pH of system II It is reduced to B (distilled ammonia), centrifuged, dried, and roasted to obtain a supported palladium-based catalyst sample.

[0066] The relationship between the sample number and the specific preparation conditions is shown in Table 1.

[0067] Table 1

[0068]

[0069]

Embodiment 2

[0070] Example 2 Determination of the content of the components in the catalysts CAT-1~CAT-16

[0071] The element composition of the samples CAT-1 to CAT-16 was measured by Ultima2 inductively coupled plasma emission spectroscopy (ICP) of Jobin Yvon Company. The results are shown in Table 2.

[0072] Table 2

[0073]

[0074]

Embodiment 3

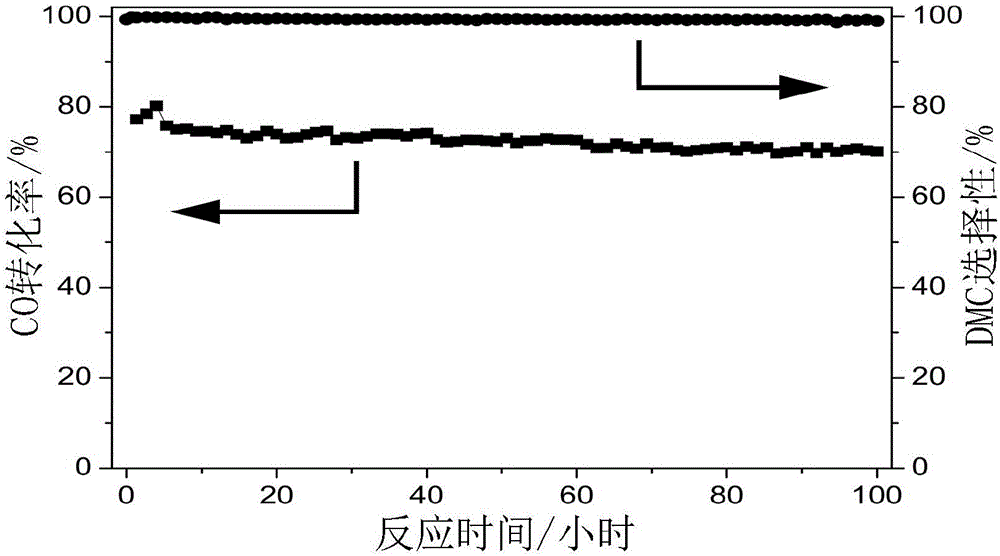

[0075] Example 3 Evaluation of catalytic performance of gas phase carbonylation of methyl nitrite to dimethyl carbonate

[0076] 200 mg of catalysts CAT-1~CAT-16 were respectively put into a fixed-bed tubular reactor, and the reaction evaluation of the gas phase carbonylation of methyl nitrite (abbreviated as MN) to prepare dimethyl carbonate (abbreviated as DMC) was performed respectively. Combine carbon monoxide, methyl nitrite, carrier gas N 2 And internal standard gas Ar (volume ratio CO: MN: Ar: N 2 = 0.17: 0.51: 0.03: 0.29), at a reaction pressure of 0.1 MPa, a reaction temperature of 120 °C, and space velocity = 2500 h -1 The catalysts CAT-1~CAT-12 were contacted respectively under the conditions to obtain the product dimethyl carbonate. The CO conversion rate and DMC selectivity of the catalysts CAT-1~CAT-16 are shown in Table 3.

[0077] The product was detected by Shimadzu's GC-2014 gas chromatograph, 5A and SE-30 columns, TCD and FID dual detectors.

[0078] The conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com