Hexagonal flaky cobalt hydroxide synthesis method

A technology of cobalt hydroxide and synthesis method, applied in the direction of cobalt oxide/cobalt hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of difficult mass production, low reactant concentration, and reaction temperature High-level problems, to achieve good industrial production application prospects, short reaction time, and easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

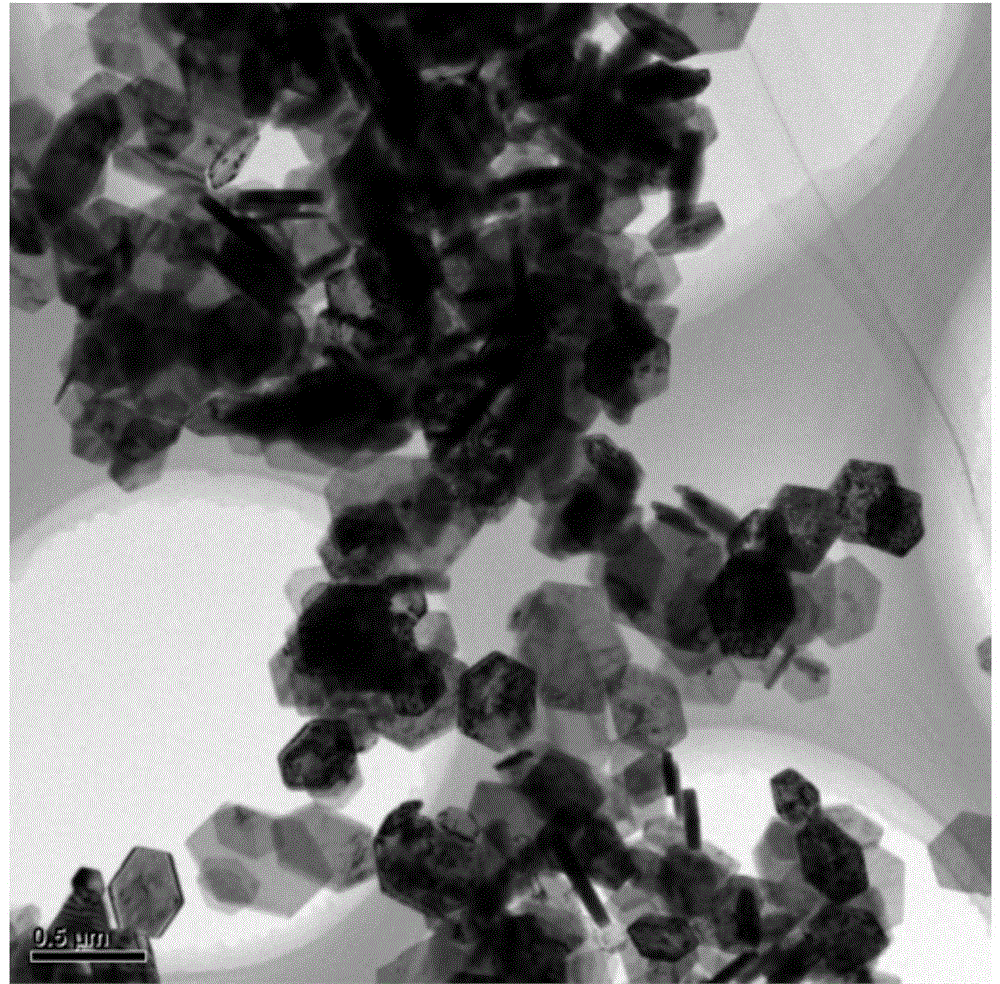

[0021] Prepare 0.5mol / L cobalt chloride aqueous solution; dissolve 10g sodium hydroxide and 1ml hydrazine hydrate in deionized water. Under the situation of vigorous stirring, add sodium hydroxide and hydrazine hydrate mixed solution rapidly in the cobalt chloride solution, make the mol ratio of sodium hydroxide and cobalt chloride be 5:1, the mol ratio of hydrazine hydrate and cobalt chloride is 0.35:1, fully reacted, washed with deionized water and absolute ethanol, and then dried at 60°C for 4 hours in a nitrogen atmosphere to obtain the following figure 1 Hexagonal nanoflakes of cobalt hydroxide are shown.

Embodiment 2

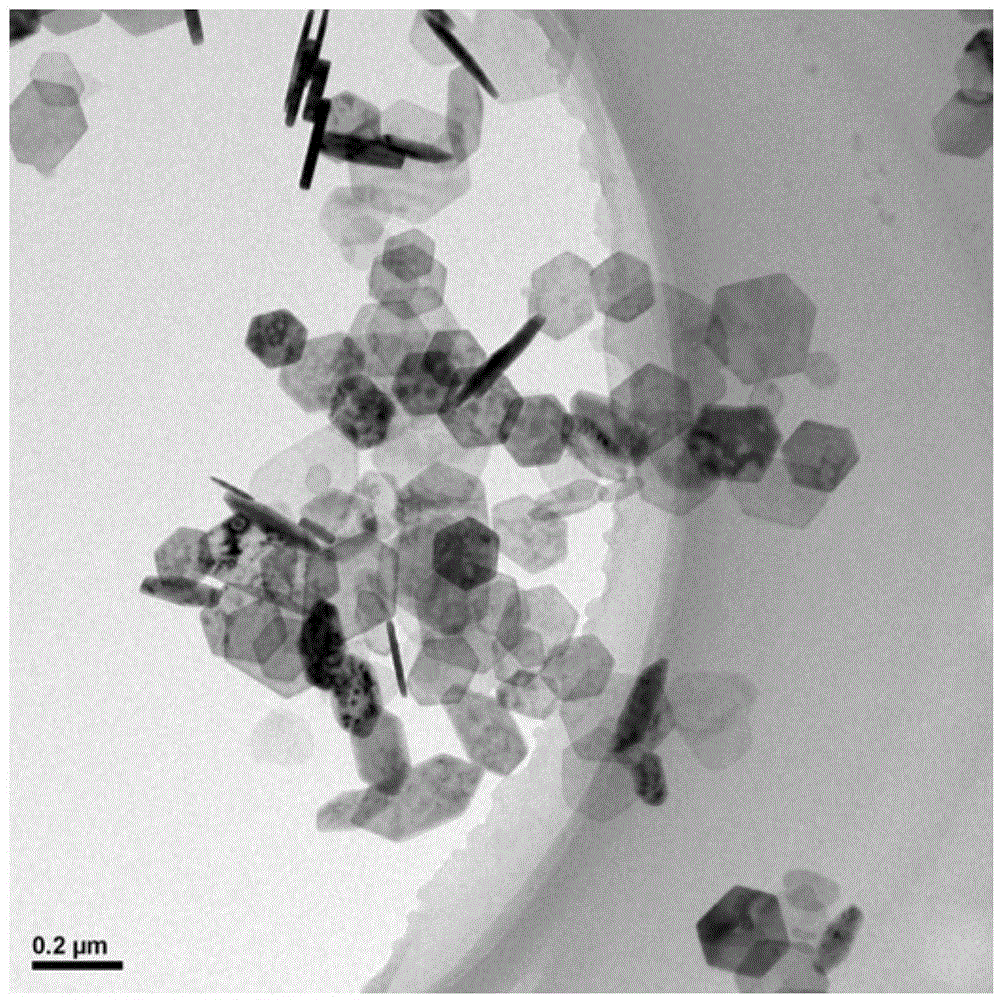

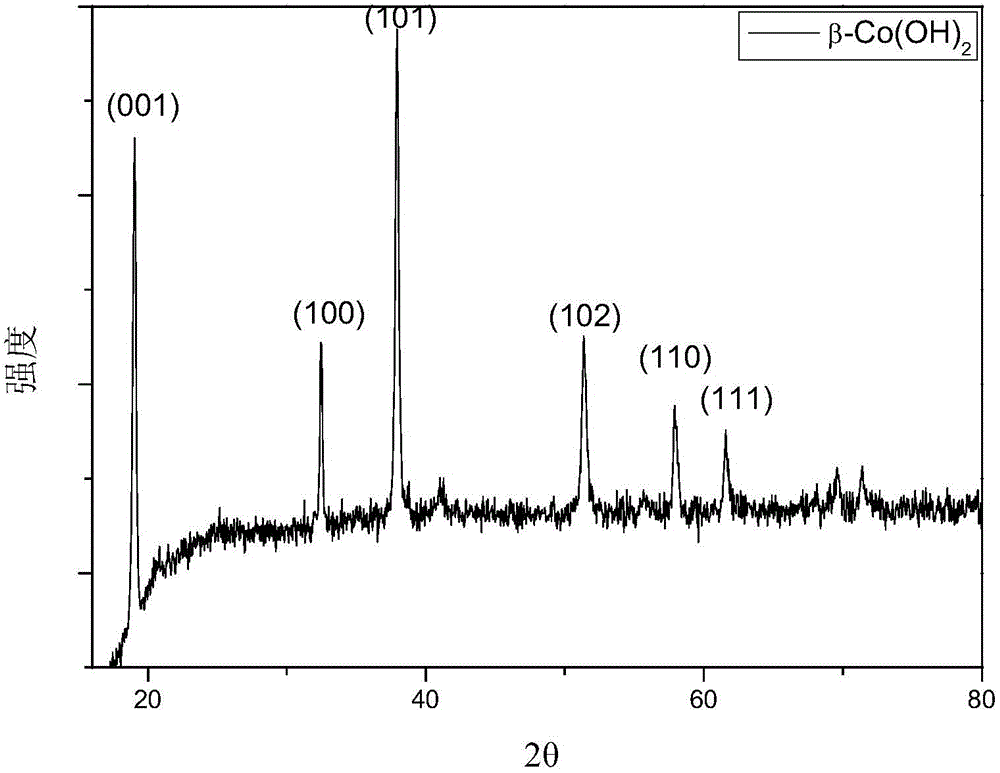

[0023] Prepare 0.005mol / L cobalt chloride aqueous solution; dissolve 0.05g sodium hydroxide and 0.5ml hydrazine hydrate in deionized water. Under the situation of strong stirring, add sodium hydroxide and hydrazine hydrate mixed solution rapidly in the cobalt chloride solution, make the mol ratio of sodium hydroxide and cobalt chloride be 2.5:1, the mol ratio of hydrazine hydrate and cobalt chloride is 17.5:1, fully reacted, washed with deionized water and absolute ethanol, and then dried at 60°C for 4 hours under a nitrogen atmosphere to obtain the following figure 2 Hexagonal nanoflakes of cobalt hydroxide are shown. image 3 It shows that the synthesized hexagonal nano-sheet cobalt hydroxide has a good crystal structure, and the synthesized hexagonal nano-sheet cobalt hydroxide is beta cobalt hydroxide.

Embodiment 3

[0025] Prepare 0.05mol / L cobalt chloride aqueous solution; dissolve 0.5g sodium hydroxide and 10ml hydrazine hydrate in deionized water. Under the situation of strong stirring, add sodium hydroxide and hydrazine hydrate mixed solution rapidly in the cobalt chloride solution, make the mol ratio of sodium hydroxide and cobalt chloride be 2.5:1, the mol ratio of hydrazine hydrate and cobalt chloride is 35:1, fully reacted, washed with deionized water and absolute ethanol, and then dried at 60°C for 4 hours in a nitrogen atmosphere to obtain hexagonal nanosheet-shaped cobalt hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com