Technology and device for composite type advanced catalytic oxidation

An advanced catalytic oxidation and catalytic oxidation technology, applied in chemical instruments and methods, special compound water treatment, water/sewage multi-stage treatment, etc., can solve the problems of low investment and operating costs, poor oxidation effect, and small mud production. , to achieve the effect of reducing operating costs, high catalytic oxidation efficiency, and low comprehensive energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

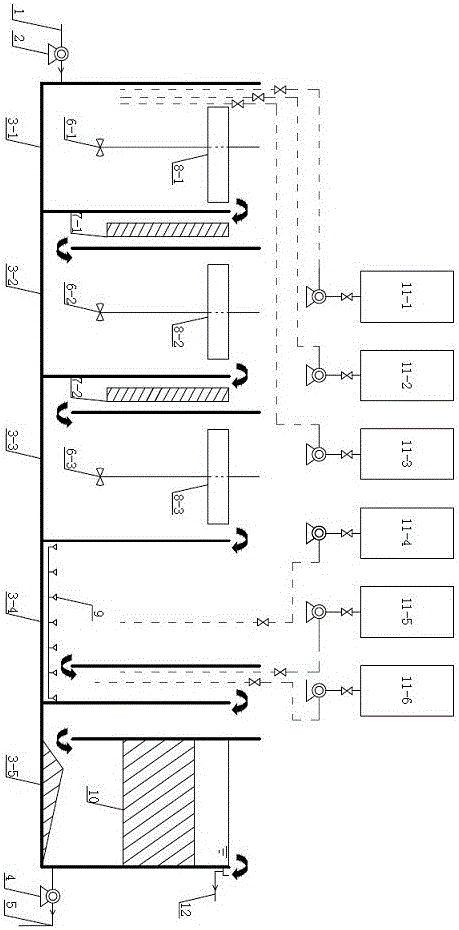

[0039] 1), the tail water of the secondary biochemical treatment process is collected into the mixing reaction tank 1 (3-1) through the water inlet pump (2);

[0040] 2), in the mixed reaction tank 1 (3-1), add known Concentrated hydrogen peroxide, ferrous iron and flow acid are stirred and mixed by the stirrer (6), so that the tail water and the medicament are fully mixed, and the pH value is adjusted to 5.5-6.5. Carry out preliminary catalytic oxidation reaction under catalysis;

[0041] 3), the mixed solution enters the catalytic oxidation tank 1 (3-2) through the composite metal oxide packing column (7), and first catalyzes through the composite metal oxide packing column (7) in the catalytic oxidation tank 1 (3-2) Oxidation reaction, then carry out catalytic oxidation reaction under the catalysis of microwave electrodeless lamp-ultraviolet light box (8), through above-mentioned two steps, finish 60-80% catalytic oxidation reaction;

[0042] 4), the mixed solution enters...

Embodiment 2

[0047] 1), the tail water of the secondary biochemical treatment process is collected into the mixing reaction tank 1 (3-1) through the water inlet pump (2);

[0048] 2), in the mixed reaction tank 1 (3-1), add known Concentrated hydrogen peroxide, ferrous iron and flow acid are stirred and mixed by the stirrer (6), so that the tail water and the medicament are fully mixed, and the pH value is adjusted to 5.5-6.5. Carry out preliminary catalytic oxidation reaction under catalysis;

[0049] 3), the mixed solution enters the catalytic oxidation tank 1 (3-2) through the composite metal oxide packing column (7), and first catalyzes through the composite metal oxide packing column (7) in the catalytic oxidation tank 1 (3-2) Oxidation reaction, then carry out catalytic oxidation reaction under the catalysis of microwave electrodeless lamp-ultraviolet light box (8), through above-mentioned two steps, finish 80-90% catalytic oxidation reaction;

[0050] 4), the mixed solution enters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com