Method for synthesizing diisostearyl malate

A technology of diisostearyl malate and diisostearyl alcohol, which is applied in the field of fine chemical product preparation, can solve the problems of affecting catalytic efficiency, slow reaction rate, waste liquid and waste water, etc., and achieve the effect of green process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

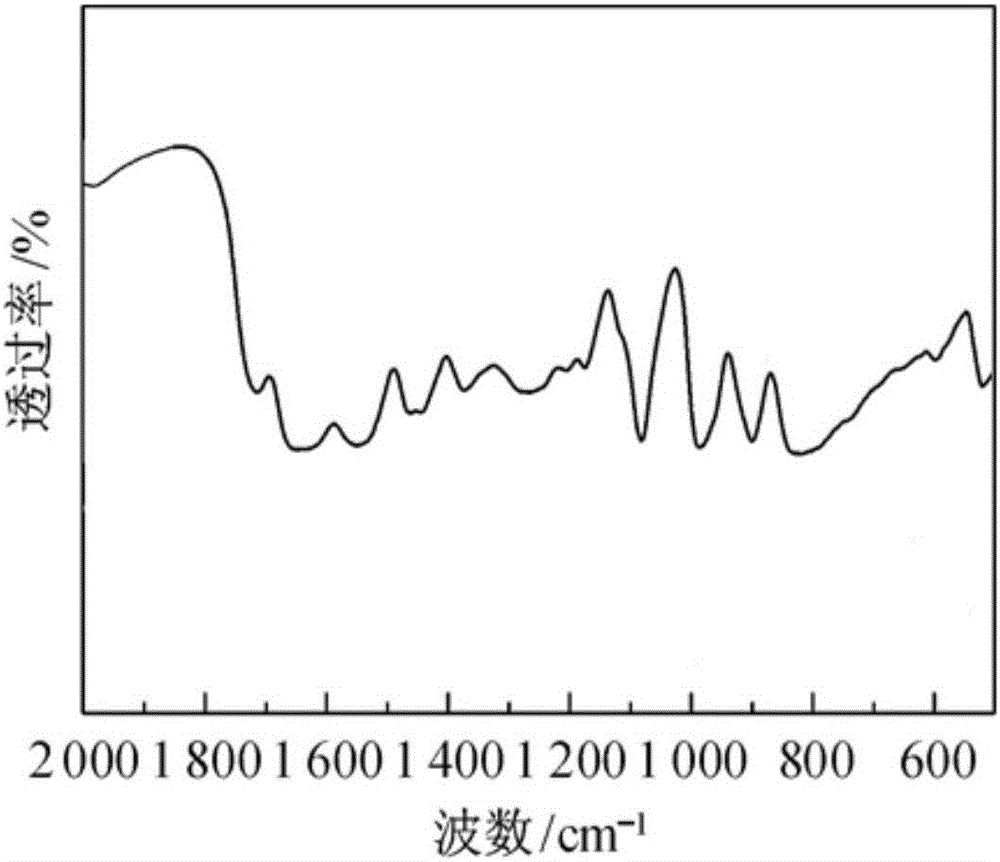

Image

Examples

Embodiment 1

[0021] Catalyst preparation: 7.6g cesium nitrate (CsNO 3 ), 9.8g lanthanum nitrate hexahydrate [La(NO 3 ) 3 ·6H 2 O] and 12g neodymium nitrate hexahydrate [Nd(NO 3 ) 3 ·6H 2 O], mixed into 40g of water, stirred for 4h, dried, then calcined in a muffle furnace at 650°C for 5h, and then heated to 850°C for 8h to obtain powder A. 14.8g copper nitrate trihydrate (CuNO 3 ·3H 2 O) and 14.6 g of phosphoric acid (H 3 PO 4 ) was dissolved in 120g deionized water to obtain solution B. 190g ammonium molybdate tetrahydrate [(NH 4 ) 6 Mo 7 o 24 4H 2 O] was dissolved in 430g deionized water, then 11.7g ammonium vanadate (NH 4 VO 3 ) was suspended therein to obtain suspension C. Add powder A to suspension C under stirring, then drop solution B into it, then stir in a sealed container at 120°C for 30h to obtain a slurry. Dry the slurry to obtain a catalyst precursor, and finally bake it in a muffle furnace at 450° C. for 15 hours. After cooling, it is broken into 80-100 mesh...

Embodiment 2

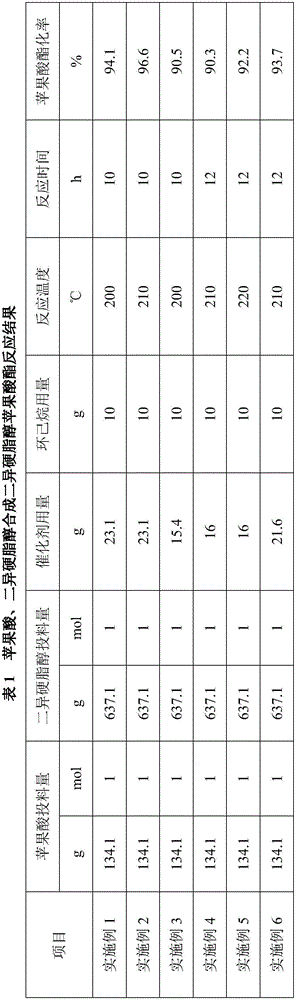

[0027] Catalyst preparation, catalyst pretreatment method, catalyst dosage, raw material dosage, and water-carrying agent dosage are the same as in Example 1, except that the synthesis reaction temperature is adjusted to 210° C., and the reaction results are shown in Table 1.

Embodiment 3

[0029] Catalyst preparation, catalyst pretreatment method, reaction temperature, raw material consumption, entrainment agent consumption are the same as embodiment 1, just catalyst consumption is adjusted to 2% of reaction substrate weight, i.e. 15.4g, and reaction result is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com