Reactive chitosan quaternary ammonium salt, and preparation method and application thereof

A chitosan quaternary ammonium salt and reactive technology, applied in the field of textile dyeing auxiliaries, can solve the problems of limited increase in dyeing rate of reactive dyes, not easy to biodegrade, poor hydrophilicity of cotton fabrics, etc., and achieve good dyeing effect , Reduce the production cost of printing and dyeing, the effect of easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

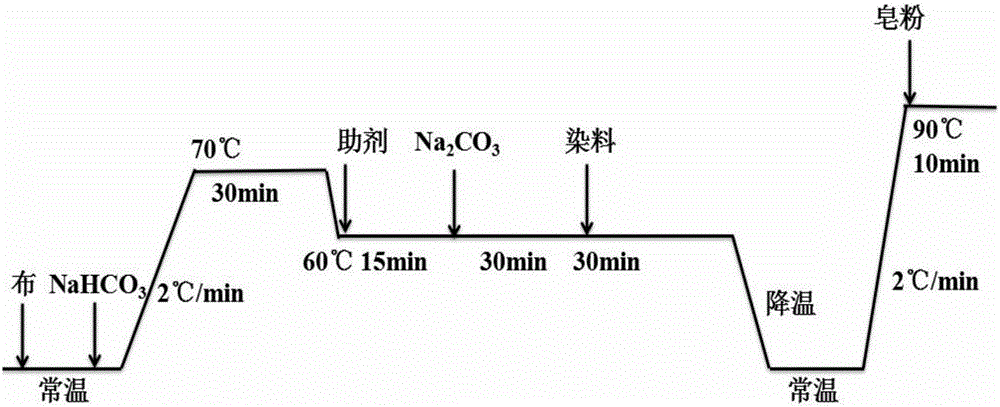

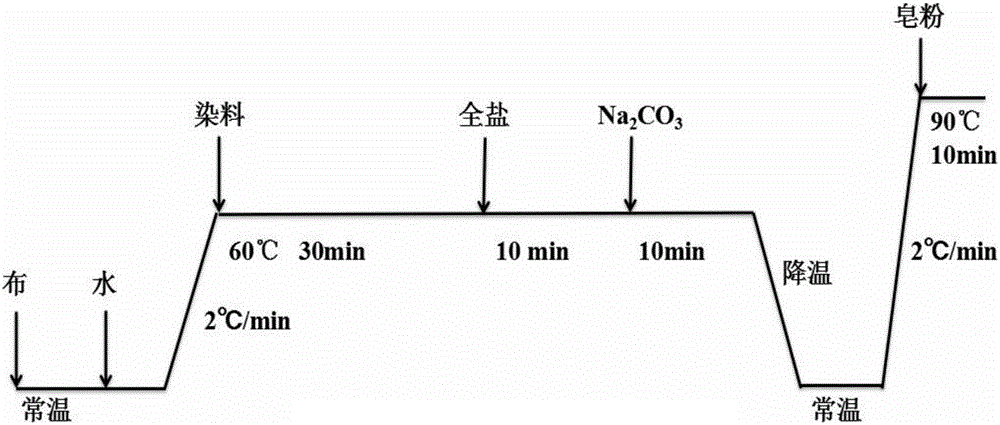

Method used

Image

Examples

Embodiment 1

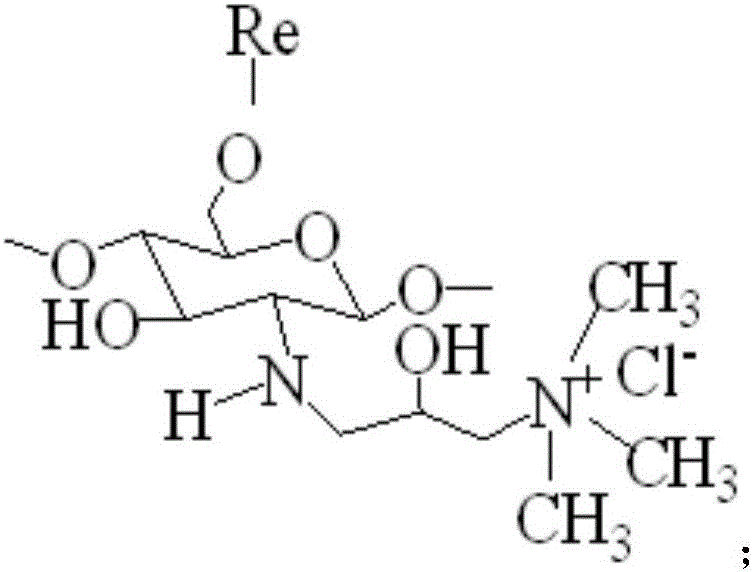

[0039] A kind of preparation method of reactive chitosan quaternary ammonium salt: first is the pretreatment of chitosan, with weight average molecular weight being 10,000, the chitosan of degree of deacetylation 40% is dissolved in the acetic acid solution of 1%, stirs Make it dissolve gradually, then add 35wt% sodium hydroxide solution drop by drop, adjust the pH=9, white precipitate will precipitate out, then soak at room temperature for 8 hours, then vacuum filter, wash with deionized water until the filtrate is neutral, then drain moisture, the product was placed in a vacuum oven to dry in vacuo.

[0040] Then the pretreated chitosan is dissolved in Virahol, heated and stirred, then slowly adding concentration is 5wt% 2,3-epoxypropyltrimethylammonium chloride solution, Friedel-Crafts reaction occurs, Among them, chitosan and 2,3-epoxypropyltrimethylammonium chloride have a molar ratio of 1:0.1, the temperature of the V-gram reaction is 40°C, and the time is 24 hours. Afte...

Embodiment 2

[0045] A kind of preparation method of reactive chitosan quaternary ammonium salt: at first be the pretreatment of chitosan, with weight average molecular weight being 60,000, the chitosan of deacetylation degree 50% is dissolved in 1% acetic acid solution, stirs Make it dissolve gradually, then add 35wt% sodium hydroxide solution drop by drop, adjust the pH=9, white precipitate will precipitate, then vacuum filter after soaking at room temperature for 8 hours, wash with deionized water until the filtrate is neutral, then drain moisture, the product was placed in a vacuum oven to dry in vacuo.

[0046] Then the pretreated chitosan is dissolved in Virahol, heated and stirred, then slowly adding concentration is 5wt% 2,3-epoxypropyltrimethylammonium chloride solution, Friedel-Crafts reaction occurs, Among them, chitosan and 2,3-epoxypropyltrimethylammonium chloride are in a molar ratio of 1:2, and the temperature of the V-gram reaction is 55 ° C, and the time is 28 hours. After ...

Embodiment 3

[0051] A kind of preparation method of reactive chitosan quaternary ammonium salt: at first be the pretreatment of chitosan, with weight-average molecular weight being 100,000, the chitosan of degree of deacetylation 60% is dissolved in the acetic acid solution of 1%, stirs Make it dissolve gradually, then add 35wt% sodium hydroxide solution drop by drop, adjust the pH=9, white precipitate will precipitate, then vacuum filter after soaking at room temperature for 8 hours, wash with deionized water until the filtrate is neutral, then drain moisture, the product was placed in a vacuum oven to dry in vacuo.

[0052] Then the pretreated chitosan is dissolved in Virahol, heated and stirred, then slowly adding concentration is 5wt% 2,3-epoxypropyltrimethylammonium chloride solution, Friedel-Crafts reaction occurs, Among them, chitosan and 2,3-epoxypropyltrimethylammonium chloride are in a molar ratio of 1:4, and the temperature of the V-gram reaction is 65 ° C, and the time is 14 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com