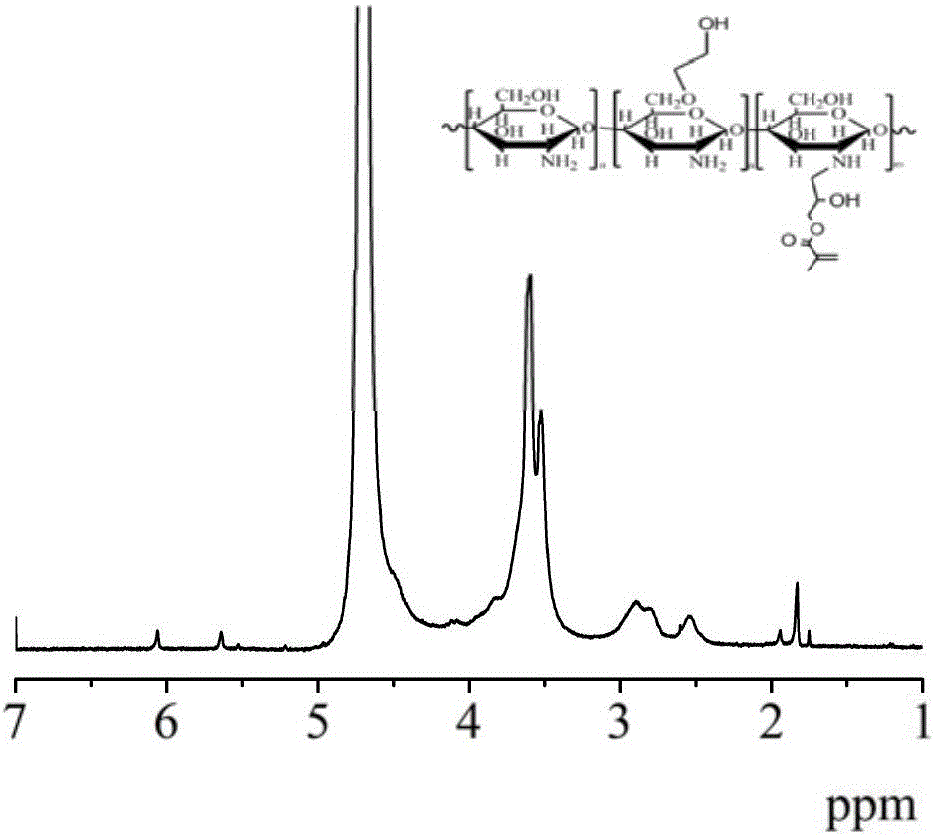

Chitosan derivative aquagel and preparation method thereof

A technology of chitosan derivatives and hydrogels, applied in medical science, prostheses, etc., can solve the problems of limited research and application, high toxicity, and affecting cell activity, etc., and achieve simple process, fast reaction speed, and uniform pore size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

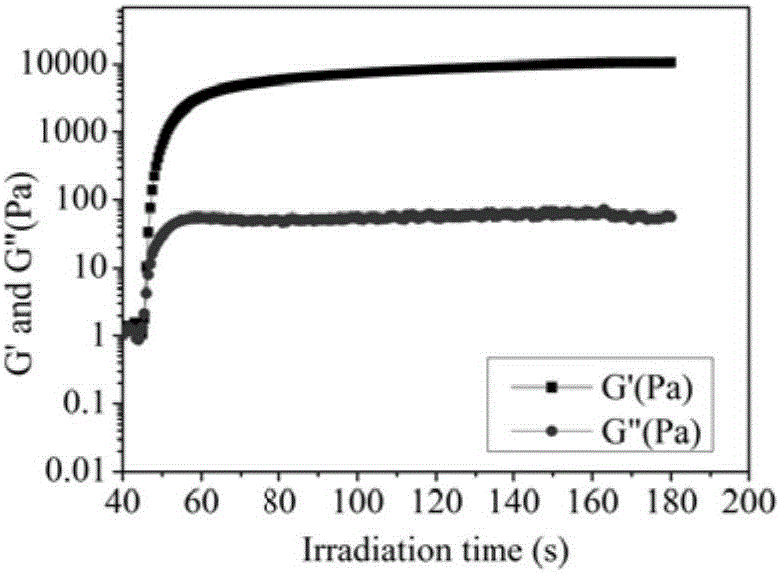

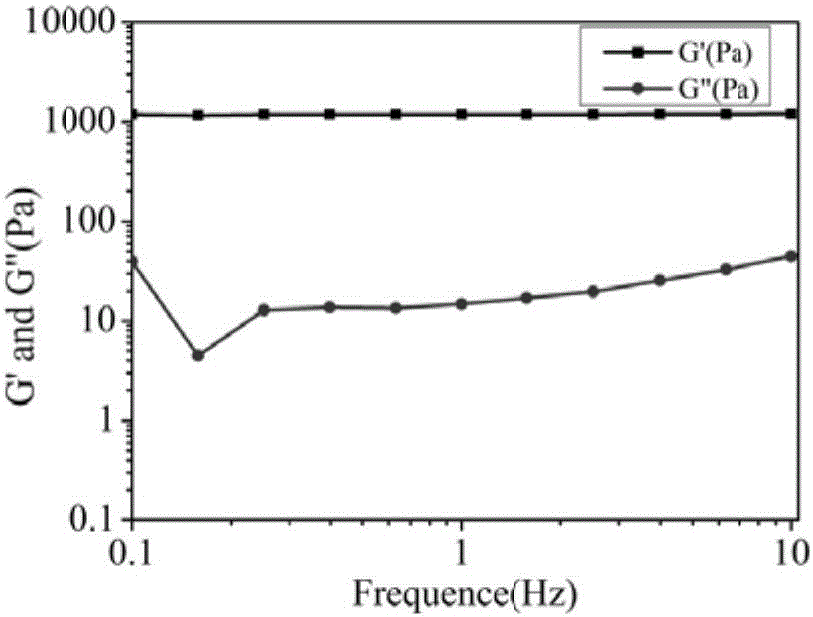

Method used

Image

Examples

Embodiment 1

[0030] 1) Dispersing chitosan with a viscosity-average molecular mass of 700kDa and a degree of deacetylation of 98% in a NaOH solution with a mass concentration of 50%, wherein the mass ratio of NaOH in chitosan and NaOH solution is 3:5; A solution of isopropanol in chlorohydrin was added thereto, and then the temperature was raised to 65° C. for reflux reaction for 5 hours; wherein, the number of chitosan repeating units: the molar ratio of chlorohydrin: isopropanol was 1:4.5:7.

[0031] 2) After the reaction, adjust the pH value to neutral with hydrochloric acid, wash the product several times with ethanol and absolute ethanol with a volume concentration of 85%, dissolve it in water after vacuum drying, and dialyze with a dialysis bag with a molecular weight cut-off of 3500Da After 48 hours, freeze-drying, specifically keeping at minus 20° C. for 72 hours and 20° C. for 4 hours, to obtain hydroxyethyl chitosan.

[0032] 3) preparation mass concentration is the hydroxyethyl ...

Embodiment 2

[0040] 1) The chitosan whose viscosity-average molecular weight is 300kDa and 95% degree of deacetylation is dispersed in the NaOH solution whose mass concentration is 30%, wherein the mass ratio of NaOH in chitosan and NaOH solution is 3:5; The isopropanol solution of chloroethanol was added therein, and then the temperature was raised to 65° C. for reflux reaction for 7 hours; wherein, the chitosan repeating unit: chloroethanol: isopropanol molar ratio was 1:3:5.

[0041] 2) After the reaction, adjust the pH value to neutral with hydrochloric acid, wash the product several times with ethanol and absolute ethanol with a volume concentration of 85%, dissolve it in water after vacuum drying, and dialyze with a dialysis bag with a molecular weight cut-off of 3500Da After 48 hours, freeze-drying, specifically keeping at minus 20° C. for 72 hours and 20° C. for 4 hours, to obtain hydroxyethyl chitosan.

[0042] 3) preparation mass concentration is the hydroxyethyl chitosan solutio...

Embodiment 3

[0045] 1) Dispersing chitosan with a viscosity-average molecular weight of 1000kDa and a degree of deacetylation of 91% in a NaOH solution with a mass concentration of 60%, wherein the mass ratio of NaOH in chitosan and NaOH solution is 3:5; The isopropanol solution of chloroethanol was added thereto, and then the temperature was raised to 65° C. for reflux reaction for 4 hours; wherein, the chitosan repeating unit: chloroethanol: isopropanol molar ratio was 1:4:7.

[0046] 2) After the reaction, adjust the pH value to neutral with hydrochloric acid, wash the product several times with ethanol and absolute ethanol with a volume concentration of 75%, dissolve it in water after vacuum drying, and dialyze with a dialysis bag with a molecular weight cut-off of 3500Da After 48 hours, freeze-drying, specifically keeping at minus 20° C. for 72 hours and 20° C. for 4 hours, to obtain hydroxyethyl chitosan.

[0047] 3) preparation mass concentration is the hydroxyethyl chitosan solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com