Water-based UV ink for inkjet printing and preparation method thereof

An inkjet printing, water-based technology, applied in the direction of ink, application, household utensils, etc., can solve the problems of short drying time, low energy consumption, incomplete curing, etc., to achieve improved friction resistance, good printing fluency, and product storage stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

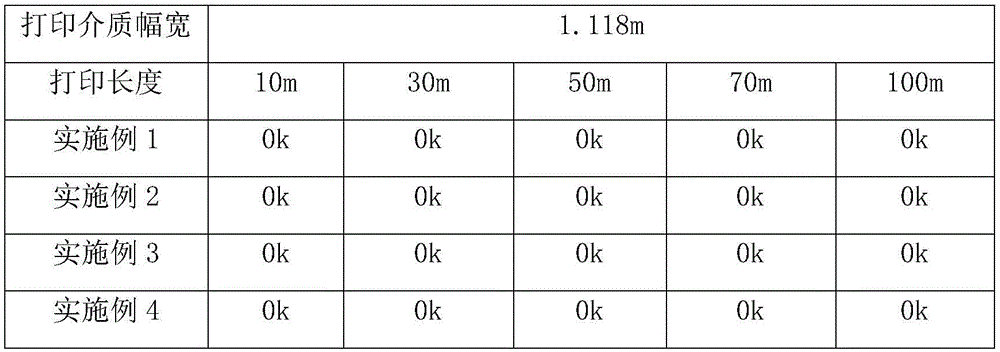

Examples

Embodiment 1

[0039] A water-based UV ink for inkjet printing:

[0040] Take the following raw materials by weight:

[0041] 3 parts of pigment red BL

[0042] Dispersant BYK-194 3 parts

[0043] Polyurethane acrylate EBECRYL 8210 40 parts

[0044] Diethylene glycol butyl ether 5 parts

[0045] Glycerin 5 parts

[0046] N-Methylpyrrolidone 7 parts

[0047] Photoinitiator KIPEM 5 parts

[0048] Surfactant BYK-348 0.5 parts

[0049] Defoamer BYK-019 1 part

[0050] Inhibitor p-hydroxyanisole 0.5 parts

[0051] 30 parts of water.

[0052] Preparation: Mix all the dispersant, 4 / 7 of the prepolymer, 5 / 9 of the co-solvent, 2 / 3 of the water and 1 / 2 of other additives, stir evenly at high speed, add all the pigments and mix evenly, transfer to the bed Type sand mill to grind to a fineness of 0.3 μm or less; add the remaining prepolymer, co-solvent, water, other additives and all photoinitiators to the ground slurry in sequence, and stir evenly to obtain water-based UV Inkjet ink.

Embodiment 2

[0054] A water-based UV ink for inkjet printing:

[0055] Take the following raw materials by weight:

[0056] Pigment Yellow 3R 4 parts

[0057] Dispersant BYK-2012 2 parts

[0058] Polyurethane acrylate KRM8721 40 parts

[0059] 6 parts triethylene glycol butyl ether

[0060] Diethylene glycol 7 parts

[0061] Cyclohexylpyrrolidone 5 parts

[0062] Photoinitiator BTC 2 parts

[0063] BPQ 2 copies

[0064] Surfactant D-502 0.5 parts

[0065] Defoamer BYK-019 1 part

[0066]Inhibitor p-hydroxyanisole 0.5 parts

[0067] 30 parts of water.

[0068] The preparation method is the same as in Example 1.

Embodiment 3

[0070] A water-based UV ink for inkjet printing:

[0071] Take the following raw materials by weight:

[0072] Pigment Blue A2R 4 parts

[0073] Dispersant BYK-194 4 parts

[0074] Epoxy acrylate EBECRYL 3701 40 parts

[0075] Diethylene glycol butyl ether 5 parts

[0076] Propylene glycol 5 parts

[0077] Glycerin 5 parts

[0078] Photoinitiator QTX 5 parts

[0079] Surfactant D-502 0.5 parts

[0080] Defoamer TEGO-830 1 part

[0081] Inhibitor p-hydroxyanisole 0.5 parts

[0082] 30 parts of water.

[0083] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com