Preparation method of borate ester braking fluid with nitrogen-containing hexatomic ring structure

A technology of borate ester and six-membered ring, which is applied in the field of preparation of nitrogen-containing six-membered ring structure borate ester brake fluid, can solve the problems that the hydrolysis ability cannot be significantly improved, has not been achieved, and the coordination ability is not as good as N atoms. , to achieve low and low temperature viscosity, increased steric hindrance, and improved hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

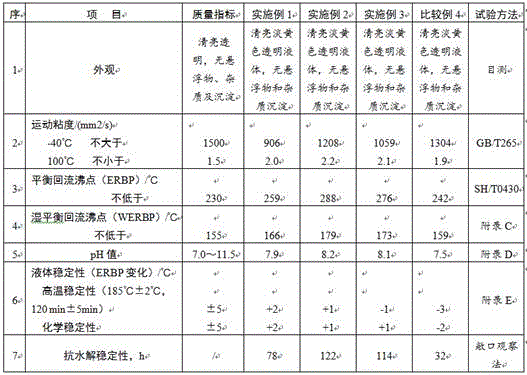

Examples

Embodiment 1

[0030] (1) Mix 129 parts of cyclohexylamine and 122 parts of salicylaldehyde in a heating device equipped with a reflux condenser, react at 100-105°C for 2 hours, and distill off under reduced pressure at a vacuum degree of 0.01-0.05MPa Moisture in the reaction, the product NA is obtained;

[0031] (2) Add 62 parts of boric acid and n-dodecyl alcohol (C 12 h 25 OH) 373 parts, continue heating to 100-110°C in the above-mentioned device for 2-4 hours to react, during the reaction process, the water in the reaction is removed by distillation under reduced pressure at a vacuum degree of 0.01-0.05MPa, and the nitrogen-containing six-membered ring structure is obtained. Borate product NB;

[0032] (3) Preparation of borate brake fluid with nitrogen-containing six-membered ring structure: Add 82 parts of diluent triethylene glycol monobutyl ether, 427 parts of polyethylene glycol ether, corrosion inhibitor benzo 5.4 parts of triazole, 33.5 parts of triethanolamine, 1.96 parts of a...

Embodiment 2

[0034] Steps (1) and (2) are the same as in Example 1, adding 46.2 parts of diluent triethylene glycol monobutyl ether, 235 parts of polyethylene glycol ether, corrosion inhibitor benzotriazole to the above borate product NB 1.2 parts, 7.45 parts of triethanolamine, 3.94 parts of antioxidant dialkylated diphenylamine, 2.0 parts of 2,6-di-tert-butyl-p-cresol, heated to 90-110°C and stirred for 1 hour. ~0.05MPa negative pressure vacuuming, cooling and cooling, filtering to obtain nitrogen-containing six-membered ring structure borate brake fluid.

Embodiment 3

[0036] Steps (1) and (2) are the same as in Example 1, adding 66 parts of diluent triethylene glycol monobutyl ether, 336 parts of polyethylene glycol ether, corrosion inhibitor benzotriazole to the above borate product NB 5.4 parts, 33.5 parts of triethanolamine, 1.96 parts of antioxidant dialkylated diphenylamine, 1.1 parts of 2,6-di-tert-butyl-p-cresol, heated to 90-110°C and stirred for 1 hour. ~0.05MPa negative pressure vacuuming, cooling and cooling, filtering to obtain nitrogen-containing six-membered ring structure borate brake fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com