Method for detecting organic volatile matters by using zirconium-based sensor

A technology of organic volatiles and sensors, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low sensitivity of VOC, and achieve the effect of simple preparation process, simple structure and good measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

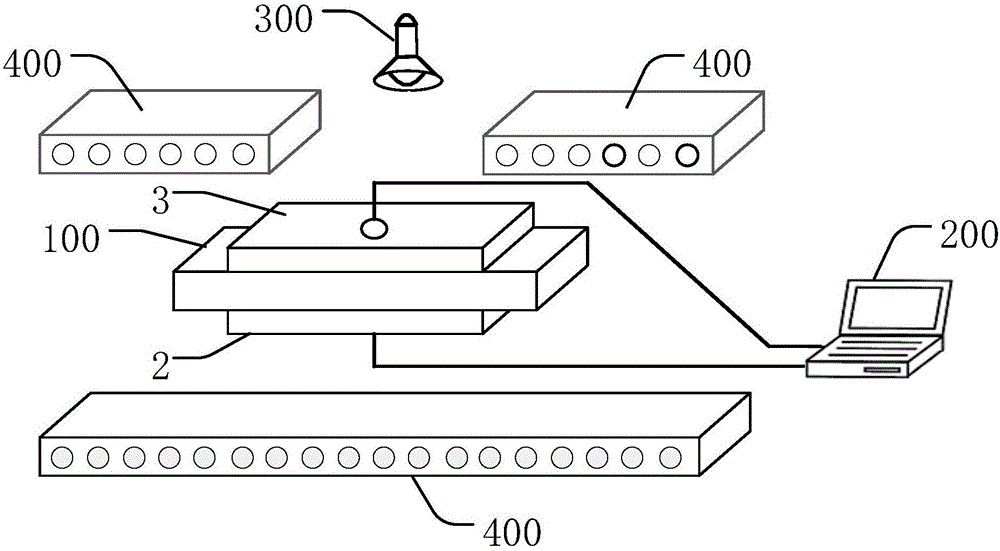

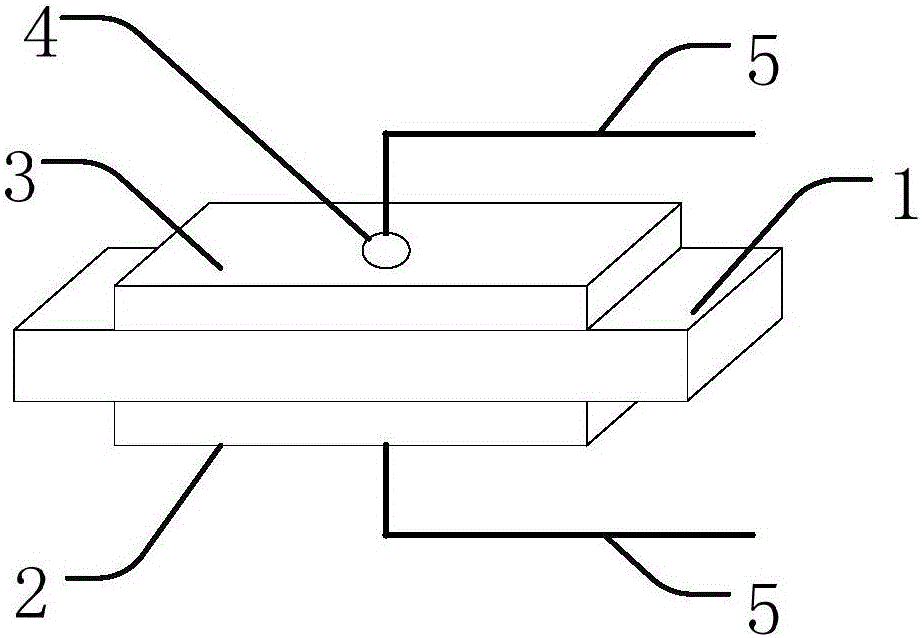

[0021] Embodiment 1: A method for detecting organic volatiles using a zirconium-based sensor, the detection device such as figure 1 As shown, the zirconium-based sensor 100 is connected with the data receiving and processing device 200, the zirconium-based sensor 100 is as figure 2 As shown, it includes a zirconium-based solid electrolyte base layer 1 and a reference electrode 2 and a sensitive electrode 3 arranged on the zirconium-based solid electrolyte base layer 1. The zirconium-based solid electrolyte base layer 1 is sintered from a 0.3mm YSZ green ceramic sheet. Electrode 2 is a porous platinum electrode. Platinum paste is printed on the surface of zirconium-based solid electrolyte base layer 1 by screen printing technology. Sensitive electrode 3 is a porous zinc oxide photosensitive electrode. After dissolving zinc oxide powder into polymer After the zinc oxide photosensitive electrode slurry is prepared in the chemical reagent, the zinc oxide photosensitive electrode ...

Embodiment 2

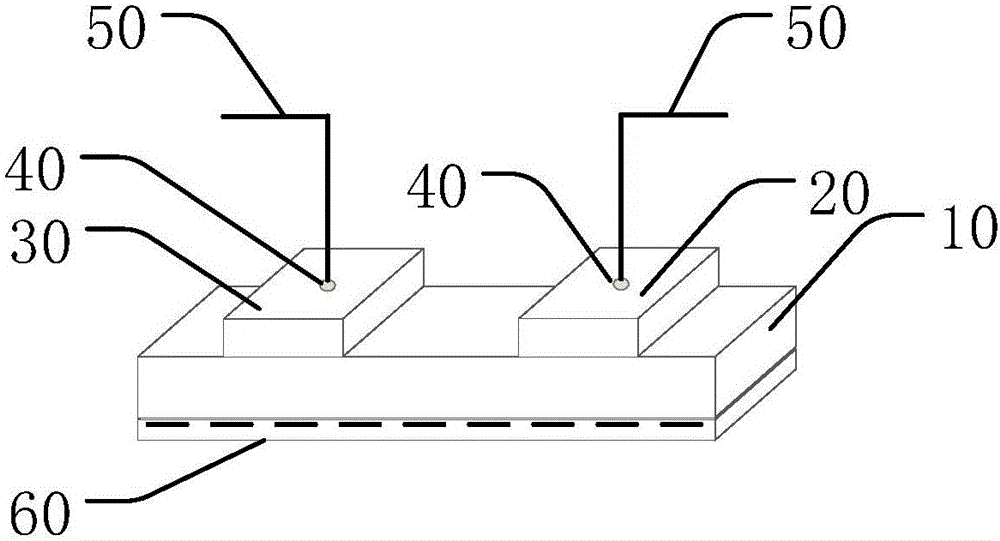

[0023] Embodiment two: if image 3 As shown, a zirconium-based sensor includes a zirconium-based solid electrolyte base layer 1 and a reference electrode 20 and a sensitive electrode 30 arranged on the same side of the zirconium-based solid electrolyte base layer 1. The zirconium-based solid electrolyte base layer 1 is made of 0.5mm YSZ green ceramic The reference electrode 20 is a porous platinum electrode, and the platinum paste is printed on the surface of the zirconium-based solid electrolyte base layer 1 by screen printing technology, and the sensitive electrode 30 is a porous zinc oxide photosensitive electrode. After dissolving the zinc oxide photosensitive electrode slurry into the polymer chemical reagent, the zinc oxide photosensitive electrode slurry is also printed on the surface of the zirconium-based solid electrolyte base layer 1 by screen printing technology, and the surface of the zirconium-based solid electrolyte base layer 1 A heating chip 60 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com