Method for removing flue gas through rosin condensate recovery

A technology for condensed water and flue gas, applied in the direction of separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve the problems of slow microbial growth cycle, high operating cost, and poor treatment effect, and achieve The processing process is simple, the safety hazard is reduced, and the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

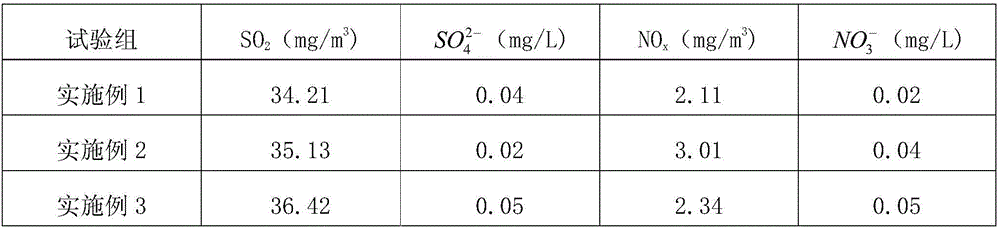

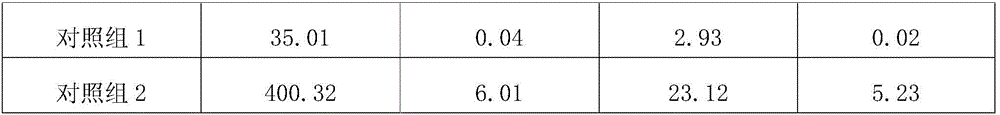

Embodiment 1

[0021] 1. Microbial activation:

[0022] (1) The configuration of the medium is according to the following medium ratio:

[0023] A medium configuration: The medium components are mixed and configured according to the following components, 0.3g of K 2 HPO 4 , 0.8 g NH 4 Cl, 1.0g yeast extract, 0.1g CaCl 2 ·H 2 O, 0.02g FeSO 4 ·7H 2 O, 5ml of 60%-70% sodium lactate solution, 800ml of distilled water, the pH value of the culture medium is 6, after the culture medium is prepared, sterilize it with steam at 120°C for 20min;

[0024] B medium configuration: The medium components are mixed and configured according to the following components, 0.5g of CH 3 COONa, 0.1 g KNO 3 , 0.02g K 2 HPO 4 , 0.02g MgCl 2 , 0.01gCaCl 2 , 800ml of distilled water, the pH value of the medium is 7, and the medium is sterilized with steam at 120°C for 20 minutes after the medium is prepared;

[0025] (2) Inoculation activation:

[0026] ① Inoculate the original species of Thiobacillus fer...

Embodiment 2

[0033] 1. Microbial activation:

[0034] (1) The configuration of the medium is according to the following medium ratio:

[0035] A medium configuration: The medium components are mixed and configured according to the following components, 0.6g of K 2 HPO 4 , 1.2 g NH 4 Cl, 1.5g yeast extract, 0.3g CaCl 2 ·H 2 O, 0.04 g FeSO 4 ·7H 2 O, 10ml of 70% sodium lactate solution, 1400ml of distilled water, the pH value of the medium is 8, after the medium is prepared, sterilize it with steam at 130°C for 30min;

[0036] B medium configuration: The medium components are mixed and configured according to the following components, 1.0g of CH 3 COONa, 0.5 g KNO 3 , 0.05g K 2 HPO 4 , 0.05g MgCl 2 , 0.03gCaCl 2 , 1500ml of distilled water, the pH value of the medium is 7.5, and the medium is sterilized with steam at 130°C for 30 minutes after the medium is prepared;

[0037] (2) Inoculation activation:

[0038] ① Inoculate the original species of Thiobacillus ferrooxidans in m...

Embodiment 3

[0045] 1. Microbial activation:

[0046] (1) The configuration of the medium is according to the following medium ratio:

[0047] A medium configuration: The medium components are mixed and configured according to the following components, 0.5g of K 2 HPO 4 , 1.0 g NH 4 Cl, 1.3g yeast extract, 0.2g CaCl 2 ·H 2 O, 0.03g FeSO 4 ·7H 2 0, 8ml of 65% sodium lactate solution, 1000ml of distilled water, the pH value of the medium is 7, after the medium is prepared, sterilize it with steam at 125°C for 25min;

[0048] B medium configuration: The medium components are mixed and configured according to the following components, 0.8g of CH 3 COONa, 0.3 g KNO 3 , 0.04g K 2 HPO 4 , 0.04g MgCl 2 , 0.02gCaCl 2 , 1000ml of distilled water, the pH value of the medium is 7.3, and the medium is sterilized with steam at 125°C for 25 minutes after the medium is prepared;

[0049] (2) Inoculation activation:

[0050] ① Inoculate the original species of Thiobacillus ferrooxidans in cul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com